Fiber-reinforced plastic and process for production thereof

A technology of fiber reinforced plastics and manufacturing methods, which is applied in thin material processing, other household appliances, transportation and packaging, etc. It can solve the problems of reduced mechanical properties of molded products, uneven distribution of reinforcing fibers, and uneven orientation, so as to improve rigidity and Excellent strength and mechanical properties, high specific modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

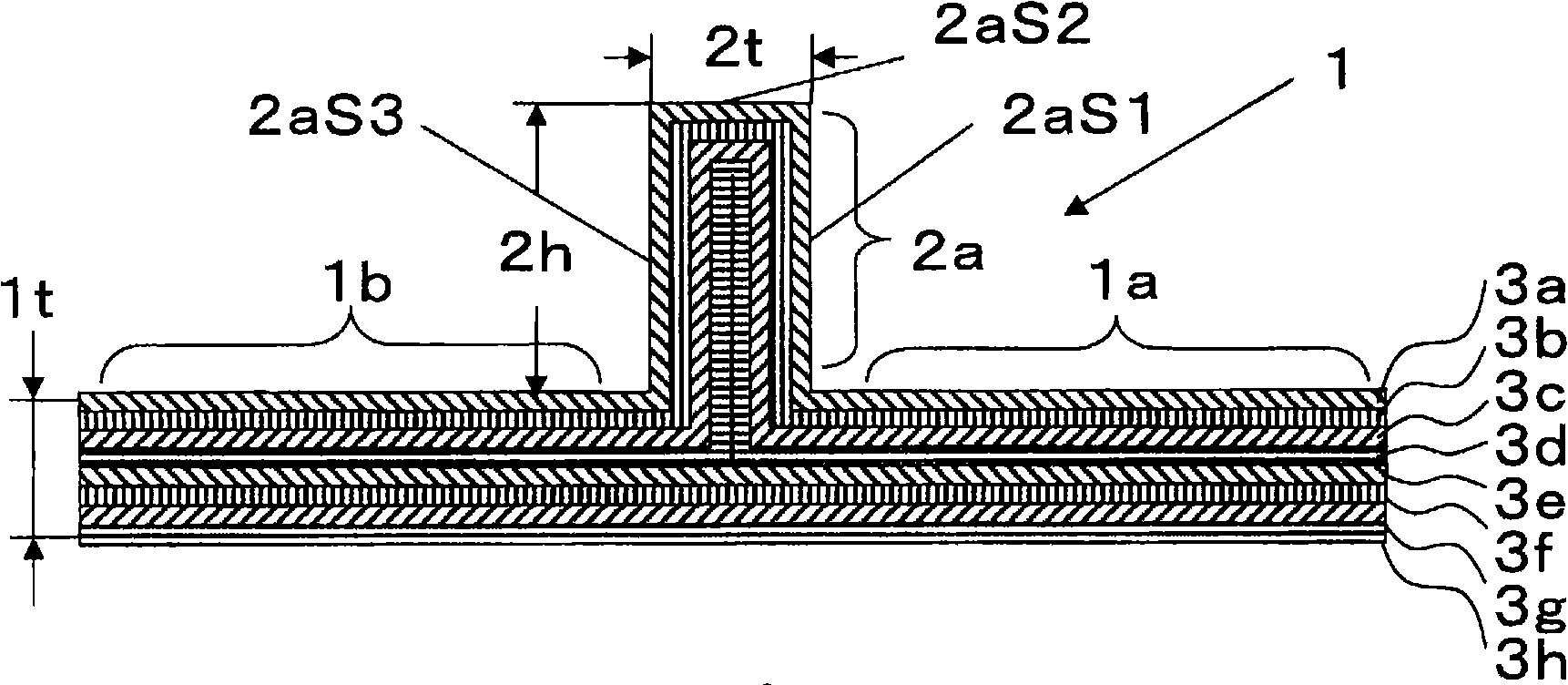

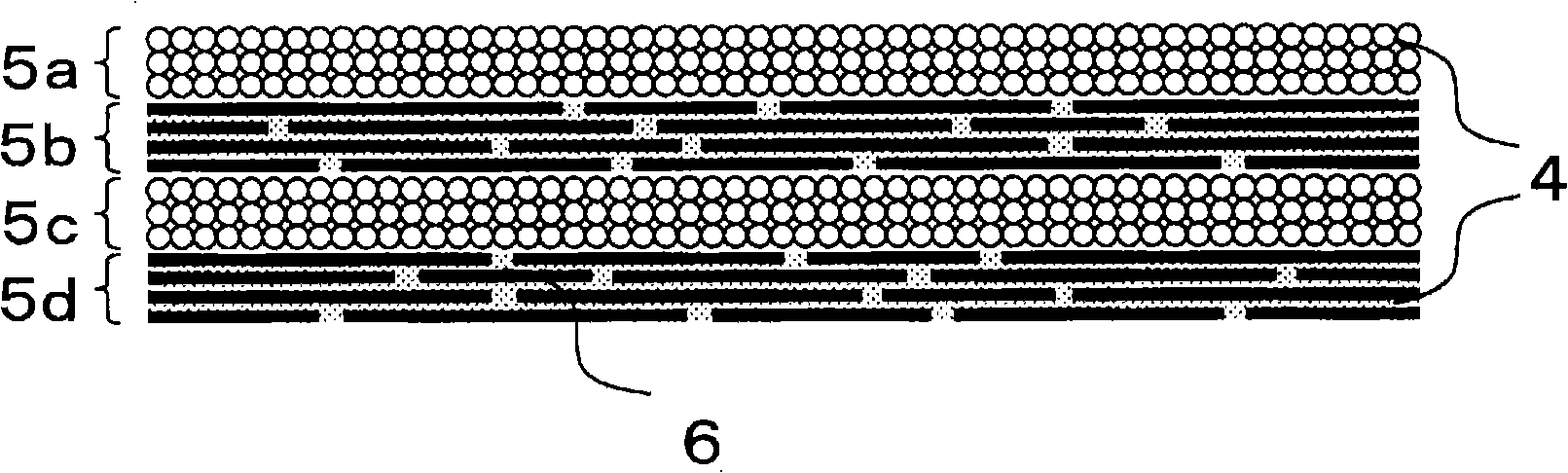

[0148] By the method of making the above prepreg, prepare Figure 6 A unidirectional prepreg sheet 11 is shown. Figure 6 In the unidirectional prepreg sheet 11, the arrangement direction (fiber length direction) of the plurality of reinforcing fibers in the unidirectional prepreg sheet 11 is indicated by the arrow symbol 9 ( Figure 6 The up and down direction in ) indicates; the direction perpendicular to the arrangement direction of the reinforcing fibers (fiber orthogonal direction) is indicated by the arrow symbol 10 ( Figure 6 in the left and right direction) indicates. The unidirectional prepreg sheet 11 is continuously inserted in the direction perpendicular to the fibers using an automatic shearing machine. Figure 6 The equally spaced and regular cuts 12 are shown. exist Figure 6Here, the width a of each incision is 10 mm, the interval (pitch) b between the incisions in the fiber length direction, that is, the cut length of the reinforcing fiber is 30 mm, and t...

Embodiment 2

[0155] In addition to using the position of the groove for forming the raised part of the upper mold to Figure 9 Except for the upper die 13B of the cross-shaped grooves 14B1 and 14B2 shown, a molded body (plate-shaped body) was produced in the same manner as in Example 1.

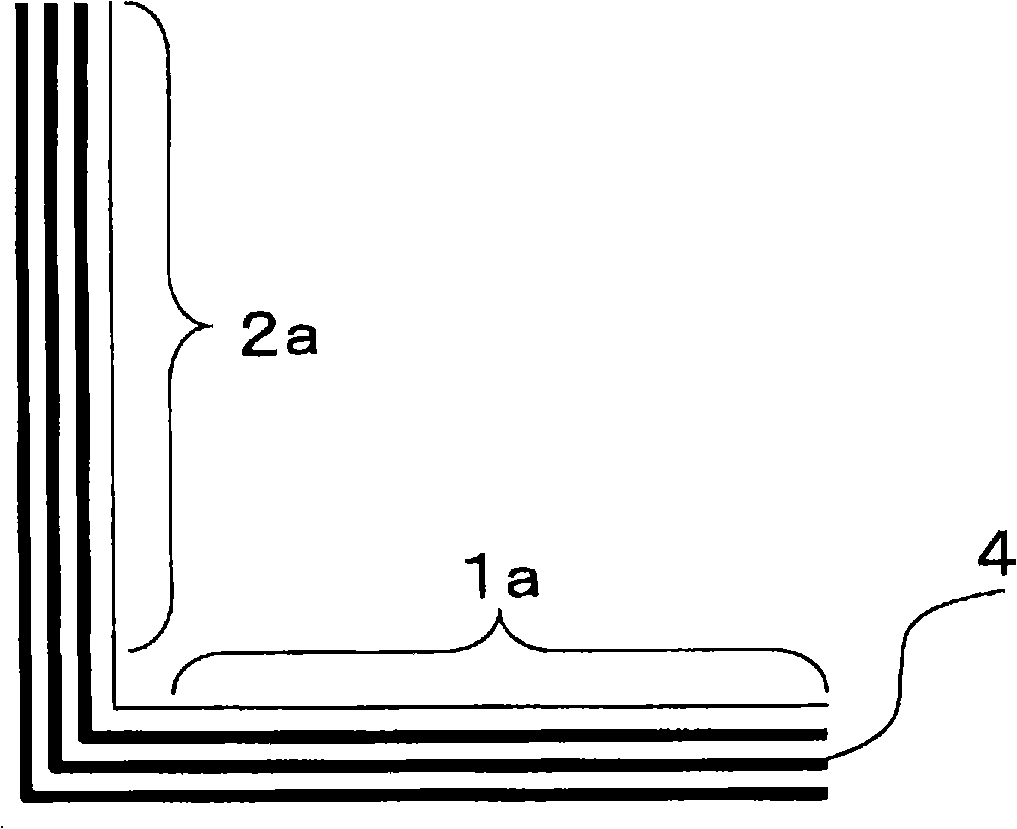

[0156] The thickness 1t of the plate-shaped part of the obtained plate-shaped body was 2.0 mm, and the reinforcing fiber was filled to the front end of the flange. When the cross-section of the flange was observed, it was as follows: figure 1 As shown, it was confirmed that a laminated structure was formed in the flange, and the reinforcing fibers in the laminated structure continued from the reinforcing fibers in the laminated structure of the plate-shaped part, and the 8 layers of the flange were formed as having a shape along the flange. , that is, layers of shapes corresponding to both side surfaces and the upper surface of the flange exist.

[0157] The results of the three-point bending test showed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com