Method for extracting tea polysaccharides and tea polyphenol from coarse old green tea

A technology of tea polysaccharides and tea polyphenols, applied in the fields of anti-toxic agents, metabolic diseases, organic chemistry, etc., can solve the problems of low yield, environmental pollution, etc., achieve high yield, avoid a lot of waste, and enhance the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

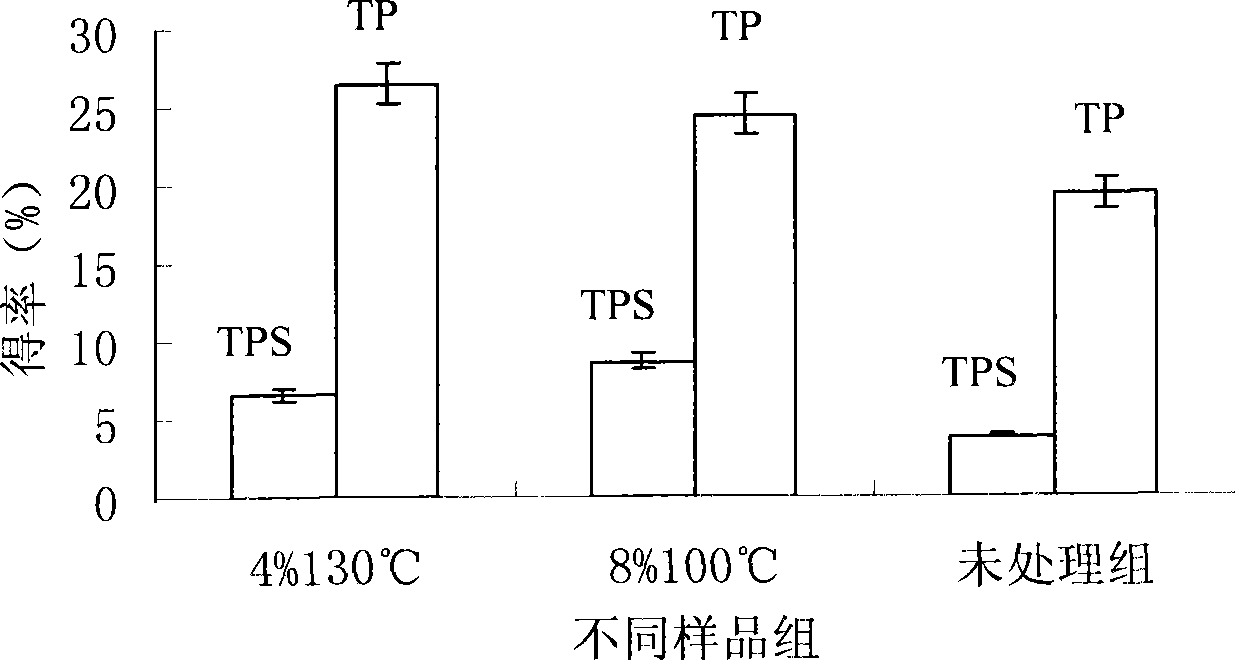

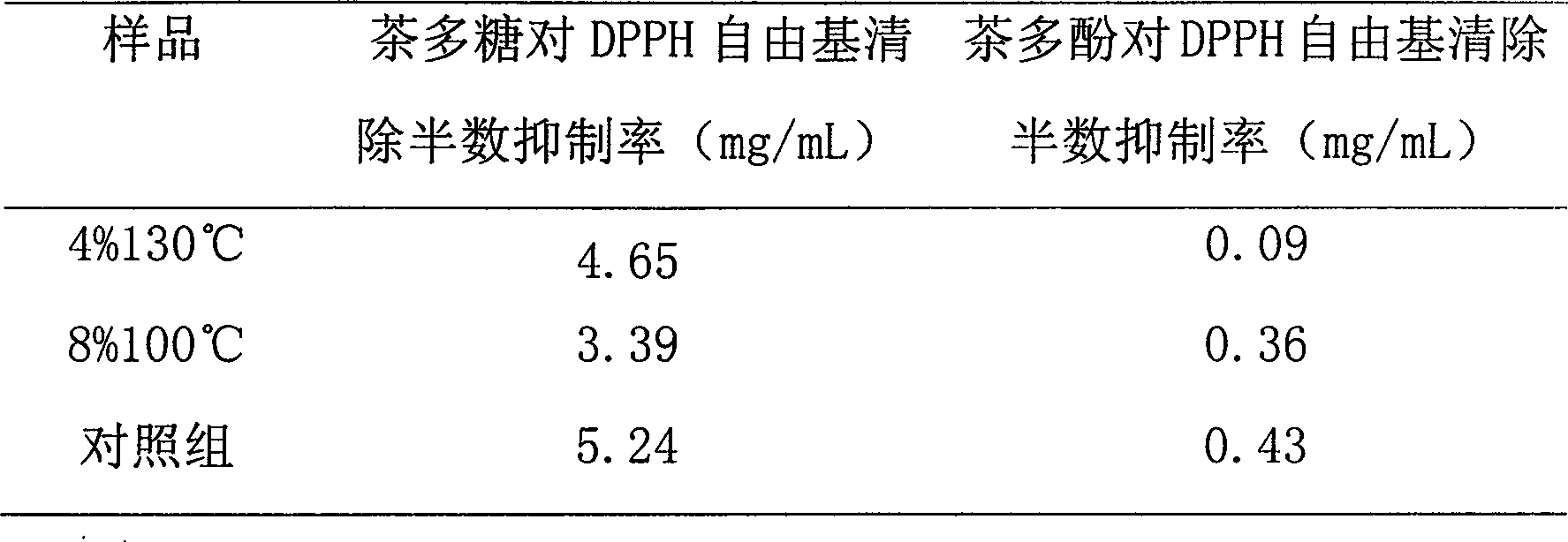

[0020] 1) adding 4% water by mass to the thick old green tea, and then extruding with a single-screw extruder at a temperature of 130° C. to pre-treat the raw materials;

[0021] 2) Add the above-mentioned crude old green tea that has been squeezed into deionized water, the mass ratio of the thick old green tea to deionized water is 1:10, then stir and extract at a temperature of 80° C. for 0.5 hours, and repeatedly extract 3 times, then filtered under reduced pressure, and the filtrates were combined to obtain a tea leaves test solution containing tea polysaccharides and tea polyphenols;

[0022] 3) At a temperature of 50° C. and a pressure of 0.09 MPa, place the above-mentioned tea leaves for test solution in a rotary evaporator and concentrate under reduced pressure to 1 / 4 of the original volume, and then add 3 times the volume to the concentrated tea leaves for test solution Precipitate with absolute ethanol, let it stand for 12 hours, then centrifuge at 2500 rpm for 8 min...

Embodiment 2

[0026] 1) adding water with 8% of its mass in the thick old green tea, and then extruding with a single-screw extruder at a temperature of 100° C. to pre-treat the raw materials;

[0027] 2) adding the above-mentioned thick old green tea that has been squeezed into deionized water, the mass ratio of the thick old green tea to deionized water is 1:5, then stirring and extracting at a temperature of 70° C. for 1.5 hours, and repeatedly extracting 4 times, then filtered under reduced pressure, and the filtrates were combined to obtain the tea leaves test solution containing tea polysaccharides and tea polyphenols;

[0028] 3) Place the above-mentioned tea leaves for test solution in a rotary evaporator at a temperature of 45°C and a pressure of 0.09 MPa to concentrate under reduced pressure to 1 / 8 of the original volume, and then add 3 times the volume to the concentrated tea leaves for test solution Precipitate with absolute ethanol, let it stand for 8 hours, then centrifuge at ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap