Anti-explosive valve

A valve body, unit valve technology, applied in building components, shockproof, construction, etc., can solve problems such as failure to reach anti-explosion level, economic losses, major accidents, etc., and achieve the effect of protecting personal and equipment safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

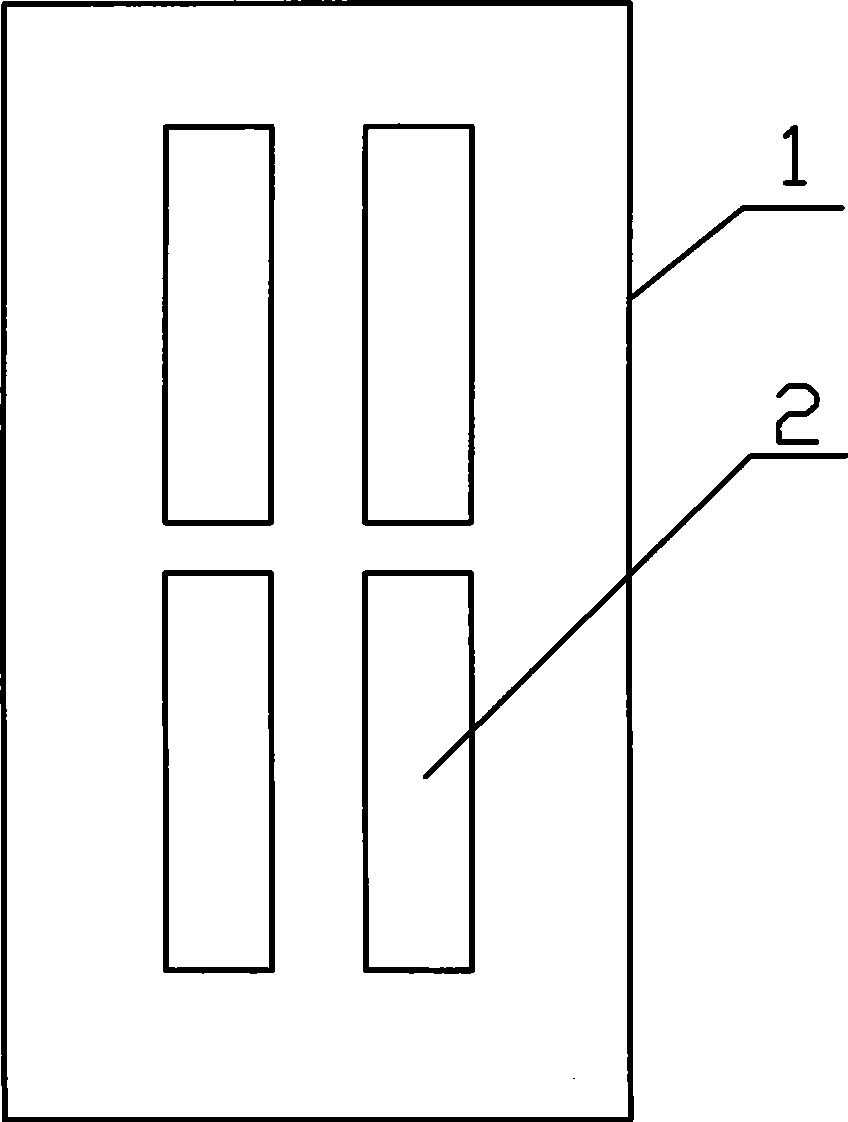

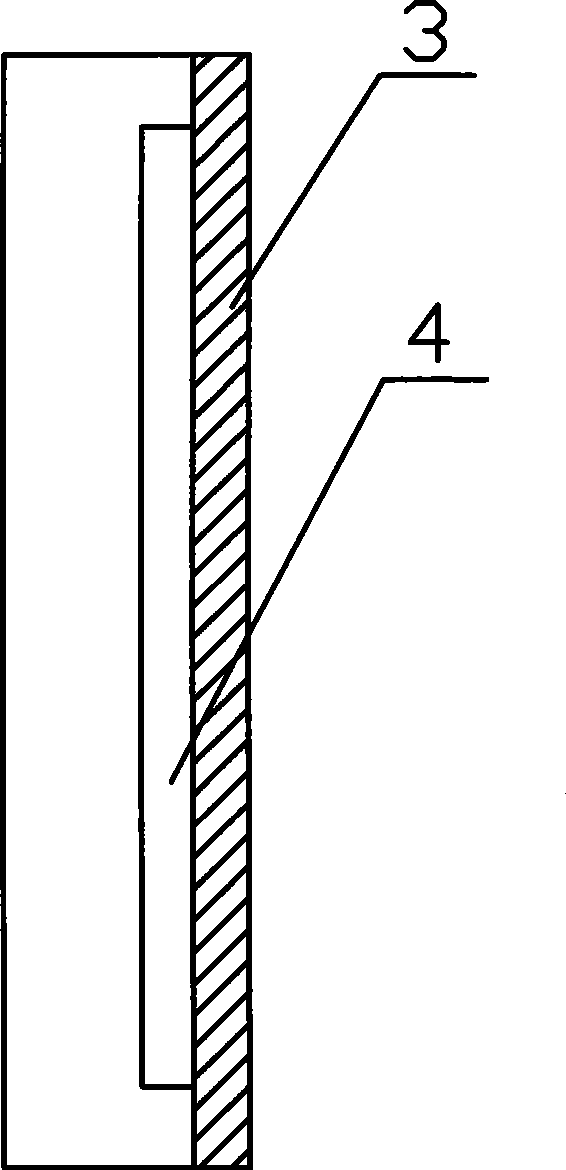

[0010] As can be seen from the drawings, the anti-knock valve is composed of a unit valve body 1, the surface of the unit valve body 1 is provided with an air outlet 2, and a bottom plate 3 is provided inside the unit valve body 1, and a slider is provided on the bottom plate 3 4. The slider 4 is elastically connected to the bottom plate 3, and the elastic connection mainly adopts a spring connection. The valve body can be fabricated from high strength structural steel for complete corrosion resistance. The unit valve body 1 can be combined in a determinant form, and specifically, valve bodies with different numbers of rows and columns can be customized for customers according to the needs of customers. The anti-knock valve is installed in the direction of the blast-facing surface of the wall, and can be installed vertically or horizontally. When selecting an anti-explosion valve, it is necessary to determine the valve body with different numbers of rows and columns according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com