Method for correcting depth trace of self-adapting well drilling

A correction method and depth tracking technology, applied in earthwork drilling, wellbore/well components, measurement, etc., can solve the problems of increased measurement error and decreased measurement accuracy, and achieve the effect of eliminating error correction, simple process, and error correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

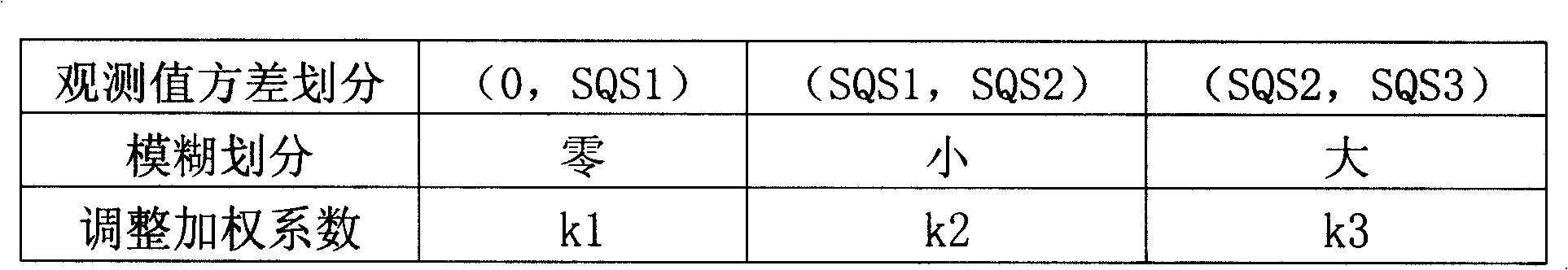

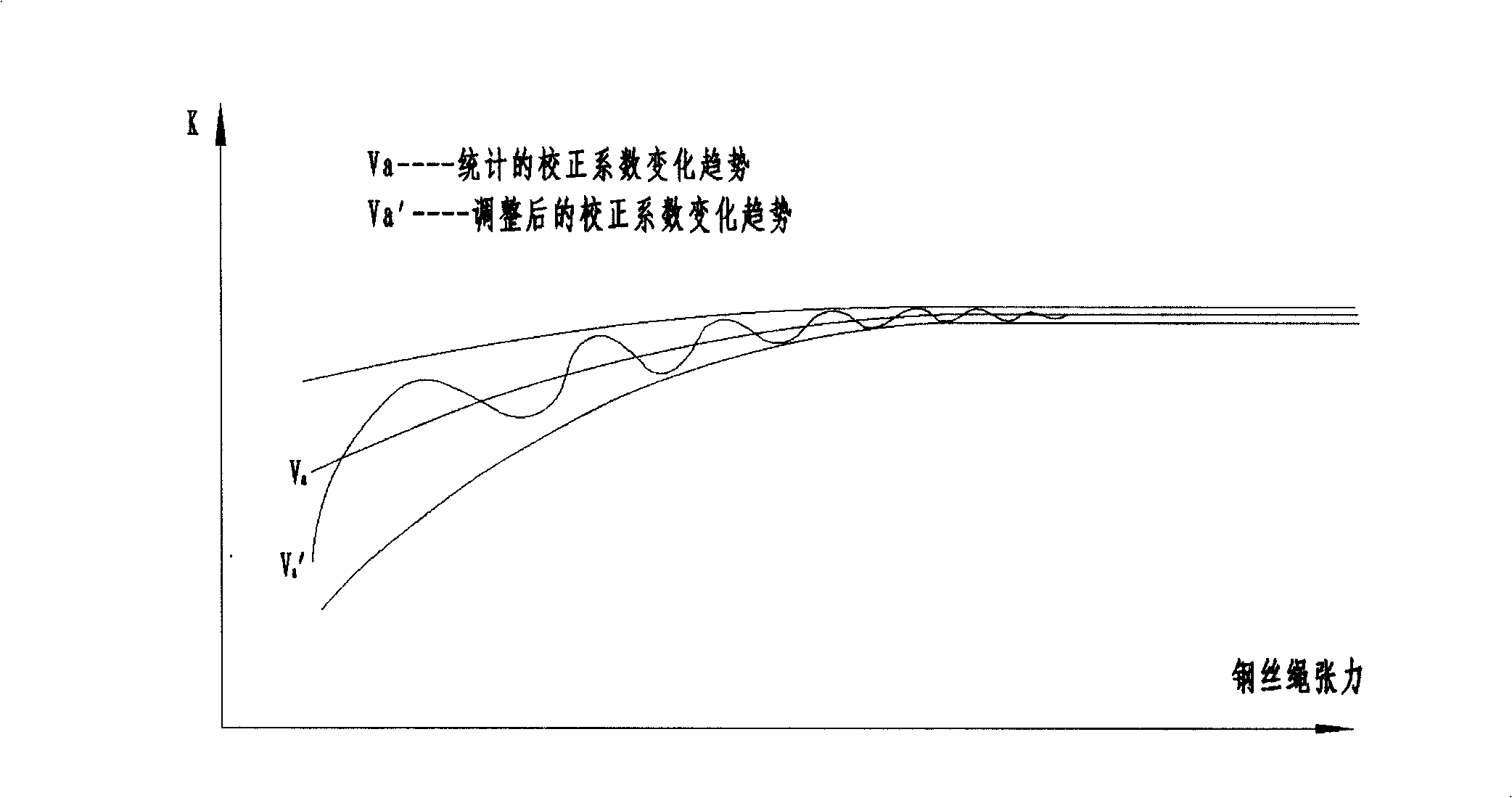

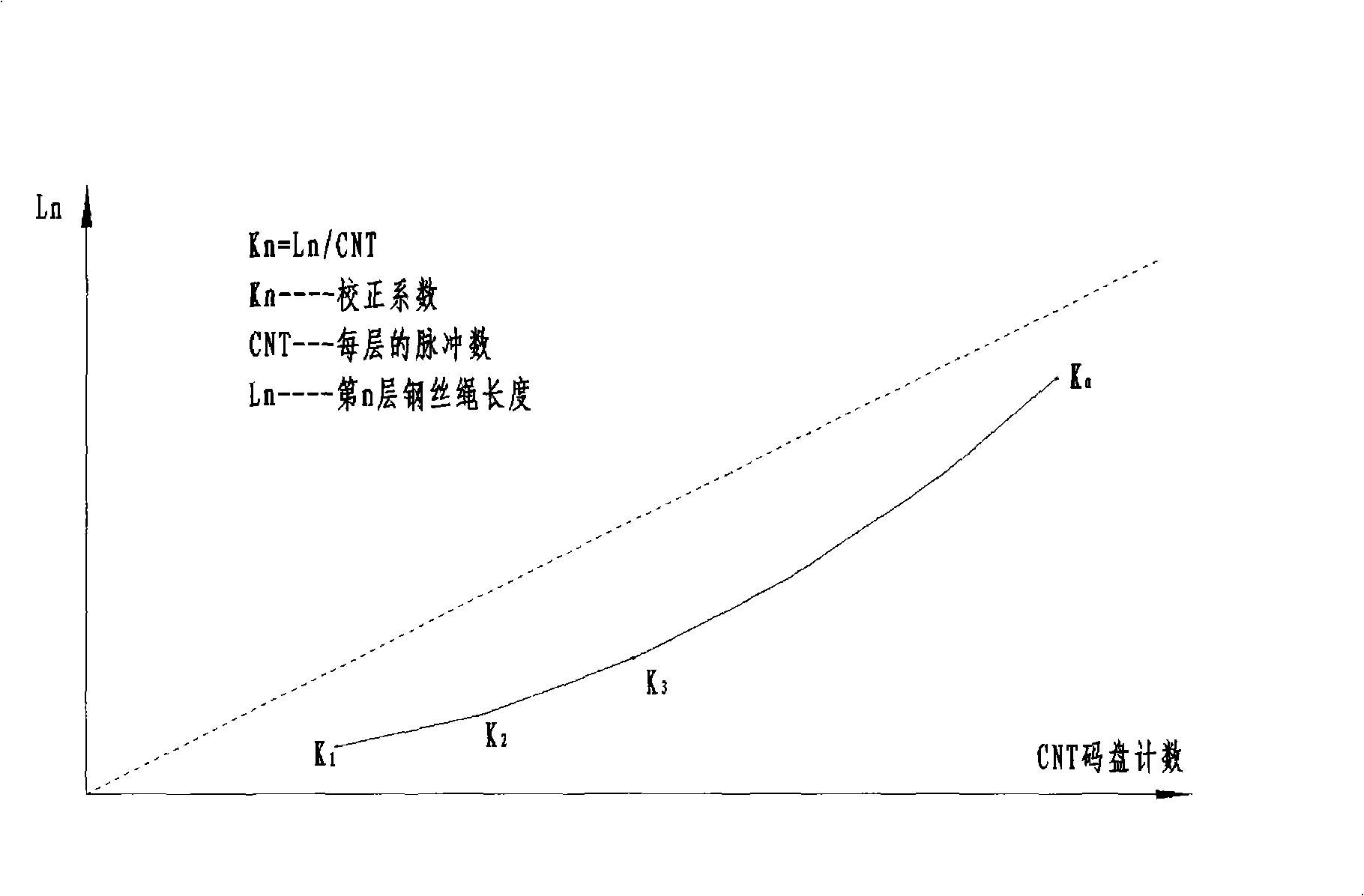

[0014] Attached below figure 1 , 2 , 3 further describe the present invention.

[0015] Carry out according to the traditional initial depth calibration method, put the kelly into the wellhead and then lift the drilling tool until the steel wire rope of the current layer on the drum is completely wrapped, keep the drilling tool stationary, measure and record the lifting height of the drilling tool ( That is, the calibration length of one layer), and record the count value at this time, the ratio of the calibration length and the count value of this layer is K1, (such as figure 1 ). After the completion, enter the next layer of calibration, continue to lift the drilling tool, and gradually calibrate the remaining layers according to the above method (actually lift the drilling tool to 15 meters to 20 meters after the end of the calibration) to obtain K2, K3...Kn, the same The correction coefficient sequence (K1, K2, K3, . . . Kn) can also be obtained through theoretical calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com