Method and device for testing microcomputer control system of diesel locomotive

A technology of microcomputer control and system testing, applied in the direction of electrical testing/monitoring, etc., to achieve the effects of small size, improved vehicle simulation test, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings.

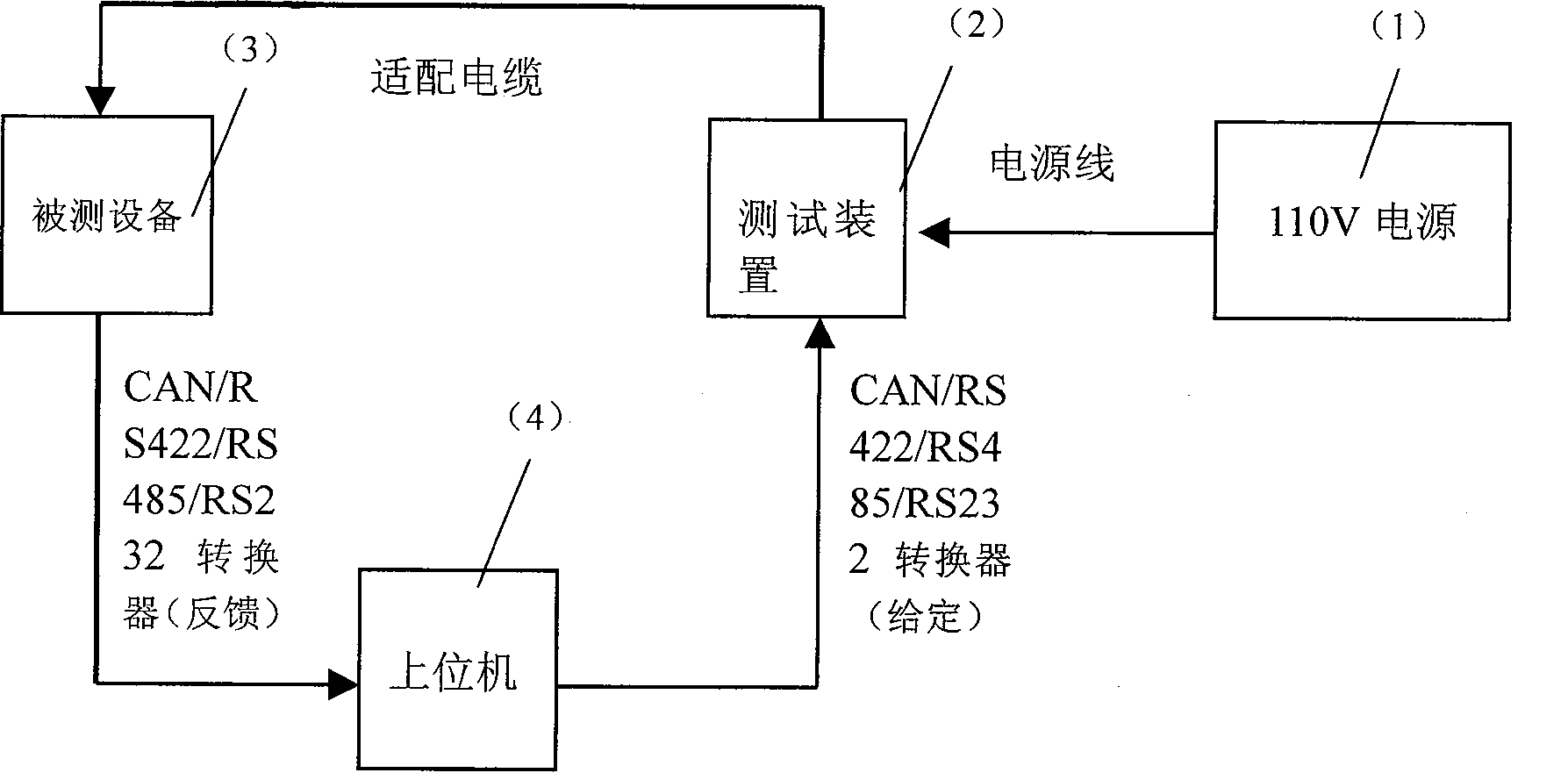

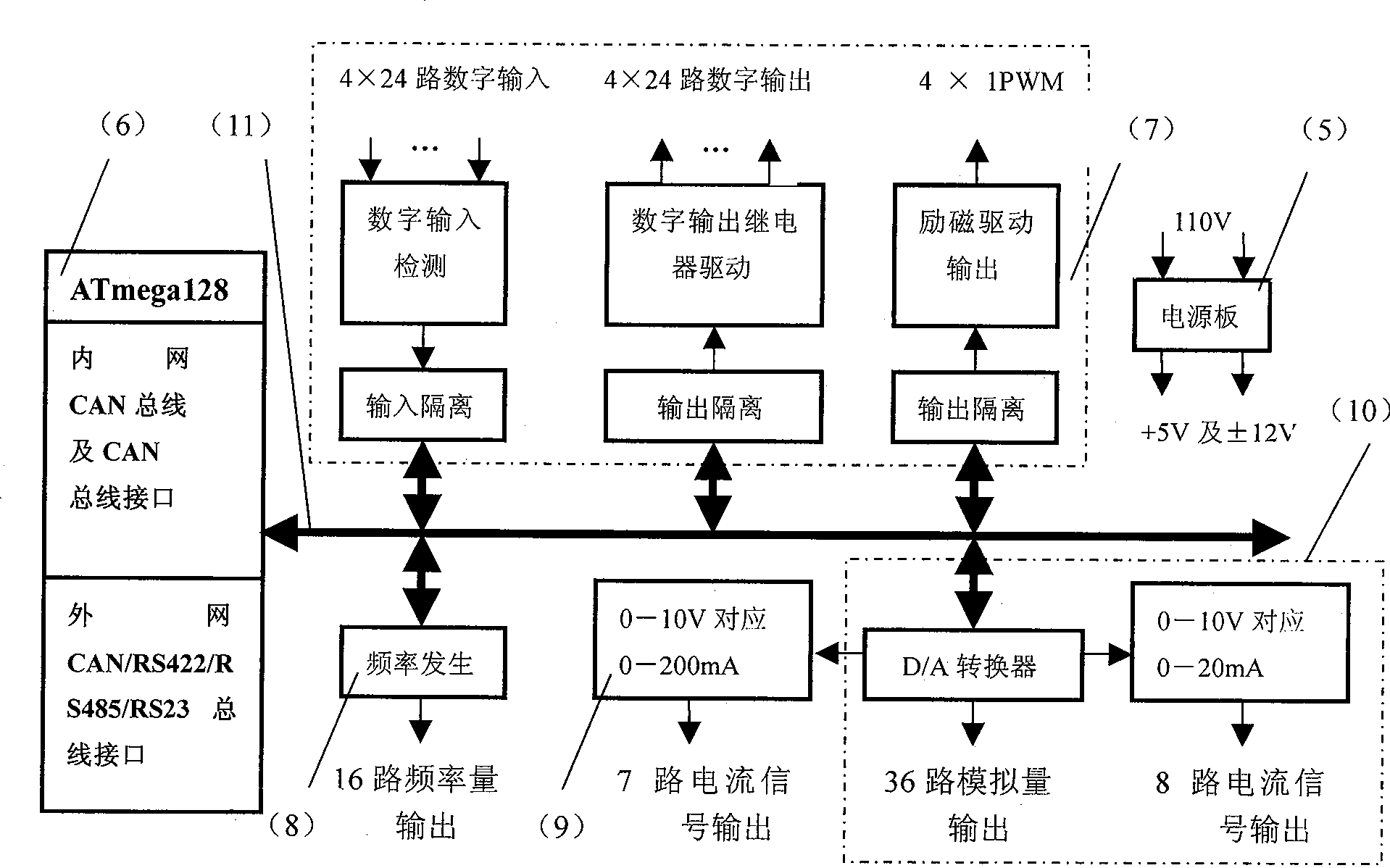

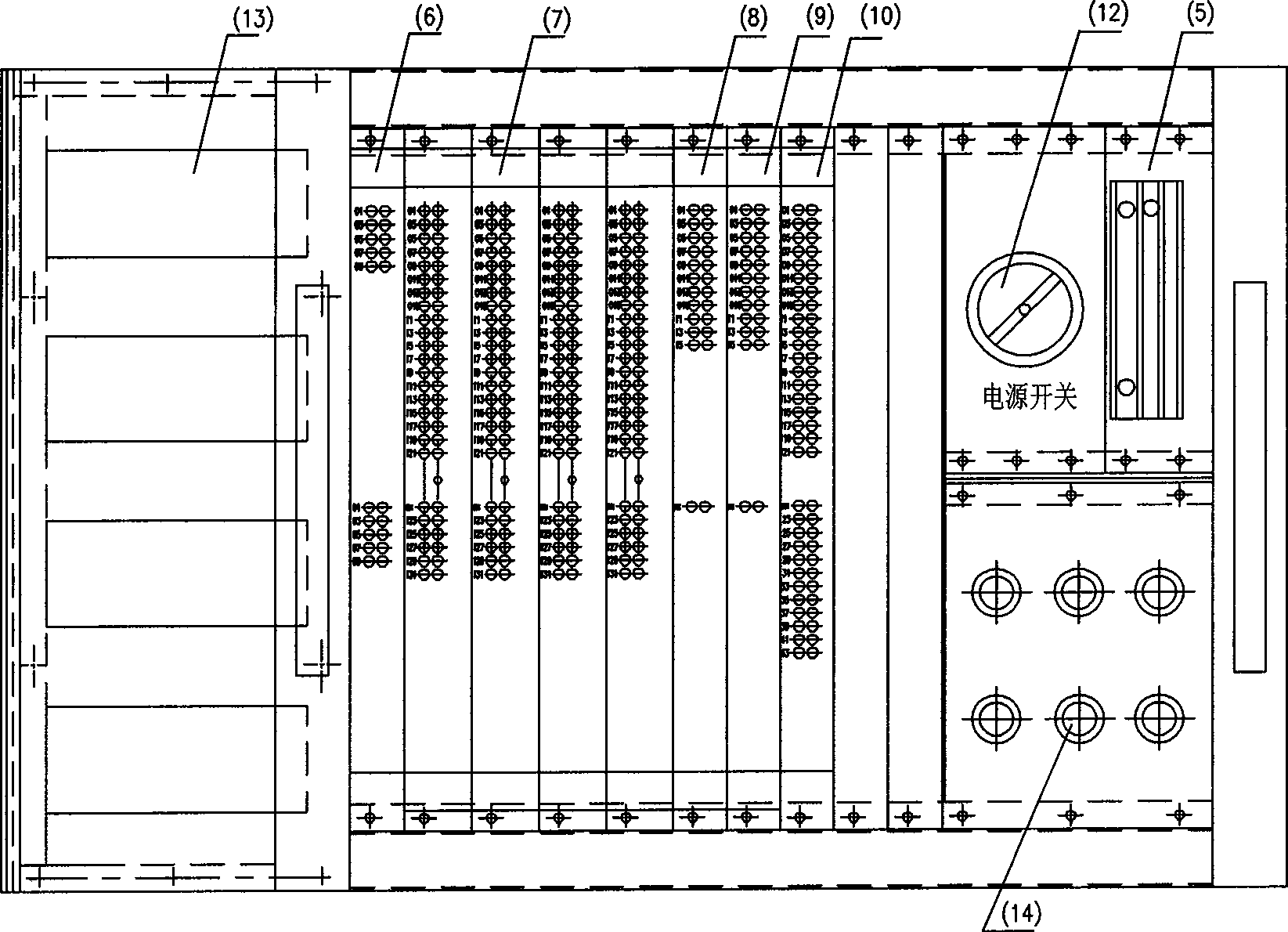

[0019] attached figure 1 It is a block diagram of the entire test system composed of the test device, the host computer, and the equipment under test. figure 1 It can be seen that the present invention is a test system for a microcomputer control system of a diesel locomotive. The whole system is composed of a 110V power supply 1 , a test device 2 , a device under test 3 and a host computer 4 . Among them, the 110V power supply 1 provides working power to the test device 2 and the device under test 3; the host computer 4 gives the command information and sends it to the test device 2 through CAN or serial bus (RS232, RS422, RS485, etc.); the test device 2 Provide various signal sources (such as digital input, digital output, analog voltage, current, etc.) to the device under test 3 through the adapter cable; the device under test 3 receives the corresponding signal, thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com