Superconducting magnet with quench protection circuit

A superconducting magnet and quench protection technology, applied in emergency protection circuit devices, superconducting magnets/coils, circuits, etc., can solve the problems of superconductor mechanical performance damage, heat dissipation, extension, etc., to avoid the degradation of superconducting wires, The effect of improving work efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

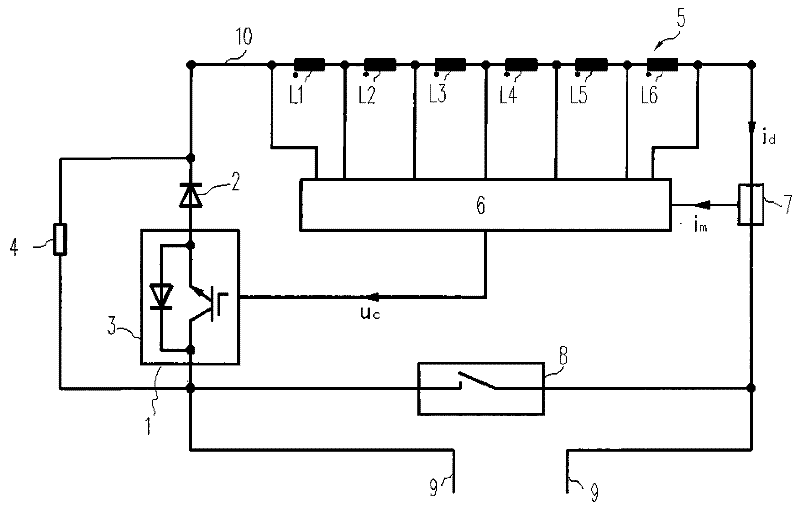

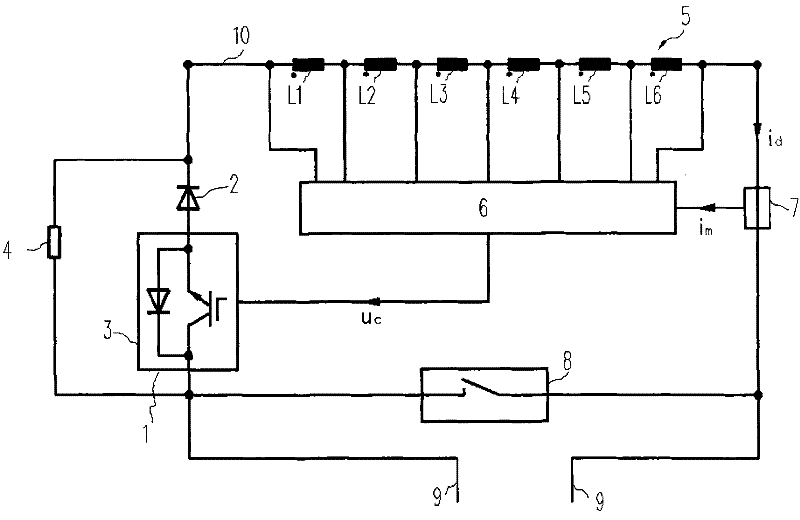

[0014] like figure 1 The present invention as shown provides a superconducting magnet quench protection circuit 1 and a superconducting magnet 10 with the protection circuit 1, the superconducting magnet quench protection circuit 1 includes a diode 2, an insulated gate bipolar transistor 3 and The energy leakage resistor 4 is connected in parallel with the energy leakage resistor 4 after the diode 2 is connected in series with the insulated gate bipolar transistor 3 .

[0015] The superconducting magnet 10 includes a superconducting magnet body 5 composed of at least six series superconducting coils L1-L6, equipped with the above-mentioned superconducting magnet quench protection circuit 1, quench detector 6, current sensor 7, short circuit 8 and a current injection wire 9, one end of the superconducting magnet body 5 in the superconducting magnet 10 is connected to one end of the short circuit 8 through the current sensor 7, and the other end of the superconducting magnet bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com