Press-working method, and press-working apparatus

A technology of stamping processing and stamping forming, which is applied in the field of stamping processing and stamping processing devices, can solve problems such as tensile stress concentration, and achieve the effect of preventing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

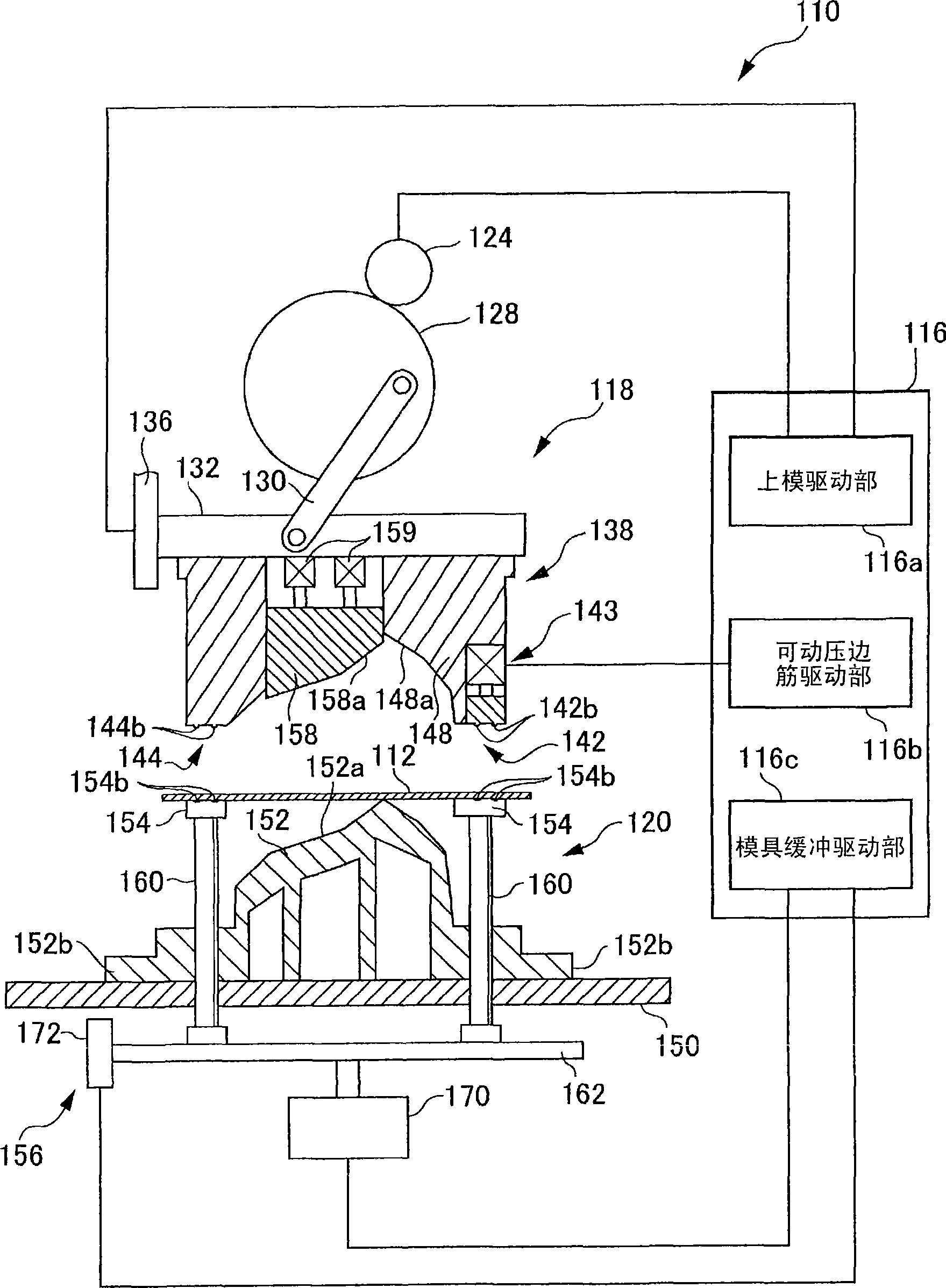

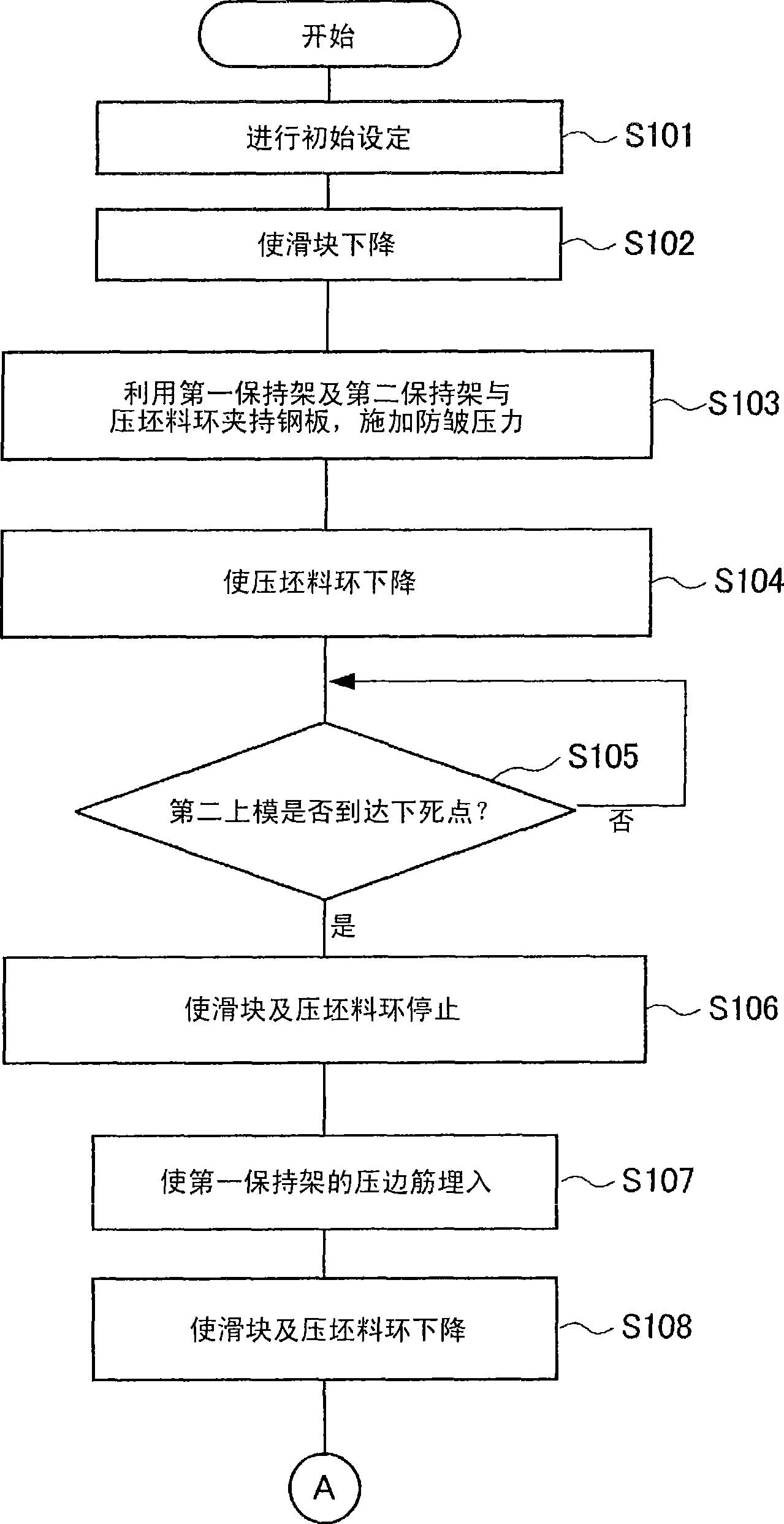

Method used

Image

Examples

no. 1 approach

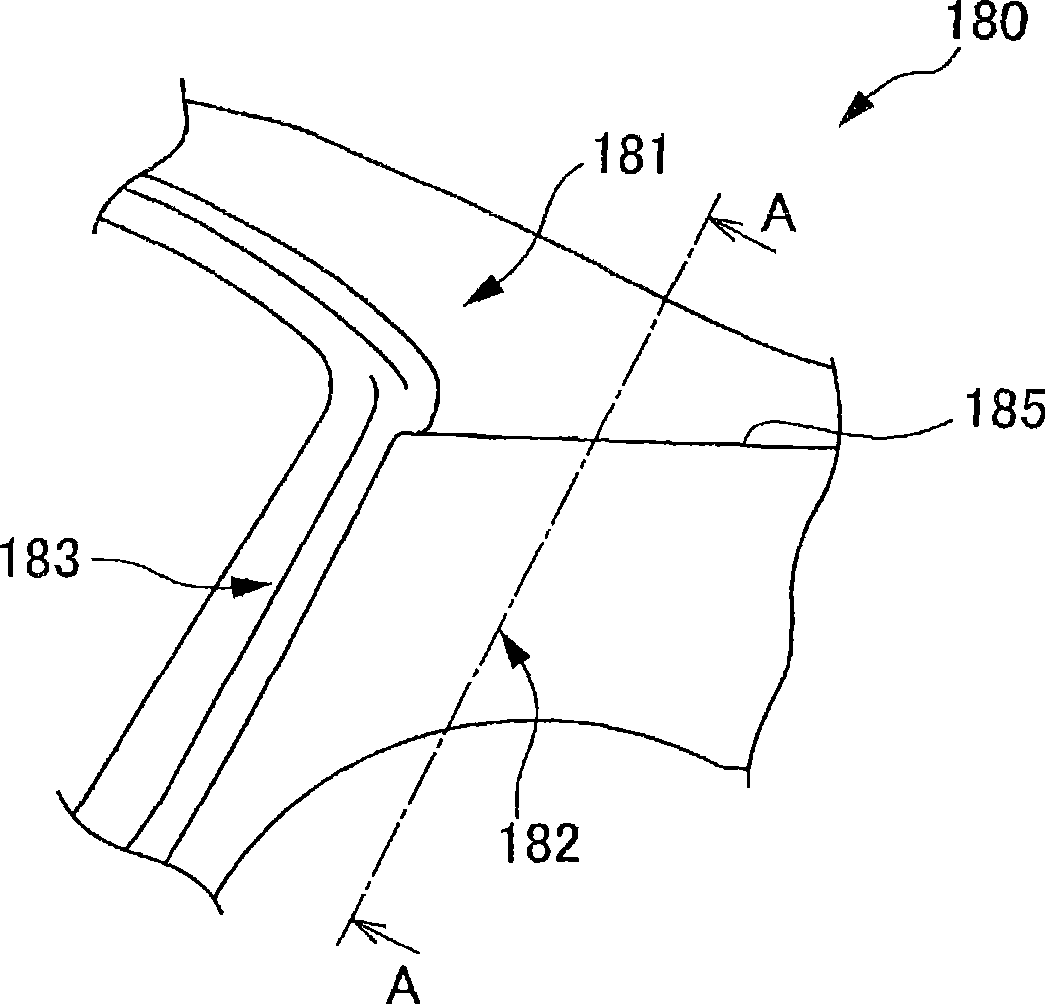

[0078] figure 1 It is a front view showing the structure of a vehicle rear side outer panel 180 as a formed product press-formed by the press working apparatus and the press working method according to the first embodiment of the present invention.

[0079] The rear outer panel 180 is made of a single steel plate, and has a substantially flat upper panel 181 and lower panel 182 , and a flange 183 that fits into a door of a vehicle (not shown).

[0080] Characteristic lines 185 serving as ridgelines formed by bending a steel plate are formed on the rear outer panel 180 . As a result, the rear outer panel 180 takes the characteristic line 185 as the boundary line according to the figure 1 The middle and upper parts are divided into upper plate 181 and lower plate 182 .

[0081] The flange portion 183 is provided on the top of the plate 181 and the bottom of the plate 182. figure 1 Center left. The flange portion 183 is formed by bending the end of the steel plate along figu...

no. 2 approach

[0140] Figure 11 It is a front view showing the structure of the vehicle rear side outer panel 280 press-formed by the press working apparatus of the 2nd Embodiment of this invention.

[0141] The rear outer panel 280 is made of a single steel plate, and has a substantially flat upper panel 281 and lower panel 282 , and a flange 283 that fits into a door of a vehicle (not shown).

[0142] The upper part 281 of the plate and the lower part 282 of the plate are separated and located at the boundary of the characteristic line 285 Figure 11 Upper and lower parts. This characteristic line 285 is an important ridgeline in design.

[0143] The flange part 283 is provided on the upper part 281 of the above-mentioned board and the lower part 282 of the board. Figure 11 Center left. The flange portion 283 is formed by bending the end of the steel plate along the Figure 11 Extend in the up and down direction. In addition, in this flange portion 283 , a recessed corner portion a...

no. 3 approach

[0191] Figure 17 It is a front view showing the structure of a vehicle rear side outer panel 380 press-formed by a press working apparatus according to a third embodiment of the present invention.

[0192] The rear outer panel 380 is made of a single steel plate, and has a substantially flat panel body 381 and a flange portion 385 that fits into a door of a vehicle (not shown).

[0193] The plate main body 381 is bordered by a characteristic line 382 formed by bending the steel plate. Figure 17 The upper and lower parts are divided into upper plate 383 and lower plate 384 .

[0194] The flange portion 385 is provided on the top of the plate 383 and the bottom of the plate 384. Figure 17 Center left. The flange portion 385 is formed by bending the end of the steel plate along the Figure 17 Extend in the up and down direction. In addition, in this flange portion 385 , a recessed corner portion adjacent to the plate portion 383 constitutes a bent portion (end portion) 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com