Solidification microstructure of aggregate molded shaped castings

A microstructure and casting technology, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problem of damage to the ductility of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment

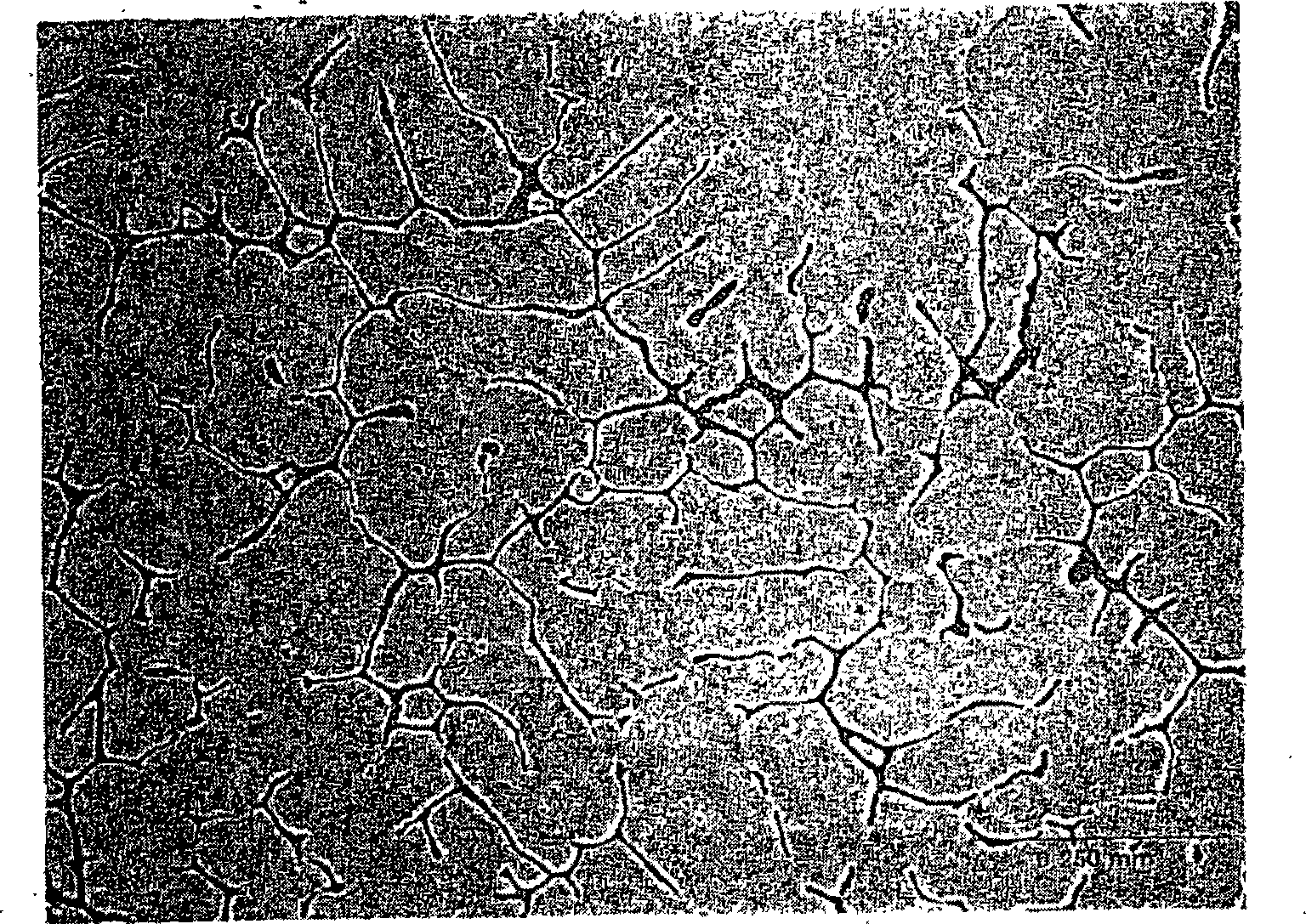

[0091] In one example of the application of the technology described in this application, a single test bar of 20 mm in diameter and 200 mm in length was molded, equipped at one end with a small conical sprue cup filled to act as a feeder . The model material was silica molding sand bound with a water-soluble inorganic binder as described in co-pending application Ser. No. 10 / 614,601.

[0092] A thermocouple was inserted into the mold cavity at the base of the feeder, at the base of the mold cavity. Place two additional thermocouples at equal intervals along the axis. The four thermocouples are labeled TC1 (riser), TC2 (top middle), TC3 (bottom middle), and TC4 (bottom).

[0093] A 6061 aluminum alloy at a temperature of 730°C (1350°F) was poured into a mold cavity positioned perpendicular to its axis. Water at 20°C (68°F) was then applied from a nozzle directed at the base of the model over a period of about 10 seconds, starting ablation of the model upwards from the base....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com