Method for improving temperature distribution in process of single crystal casting solidification

A temperature distribution and casting technology, applied in the direction of self-solidification, single crystal growth, single crystal growth, etc., can solve the problems of large undercooling, hinder the growth and expansion of single crystal, destroy the single crystallinity of the blade, etc., and achieve an optimized temperature field. Distribution, application implementation is simple and easy, and the effect of ensuring smooth growth and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

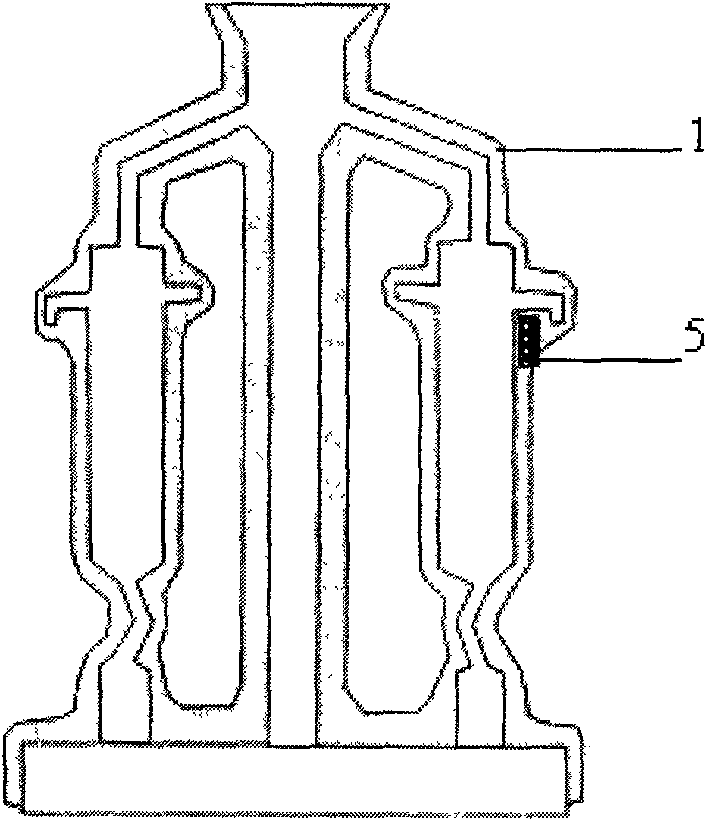

[0021] Apply the technology of the present invention to the casting of a single crystal blade, the blade length is 150mm, the material is CMSX6, and the structure of the ceramic formwork is shown in the attached figure 2 .

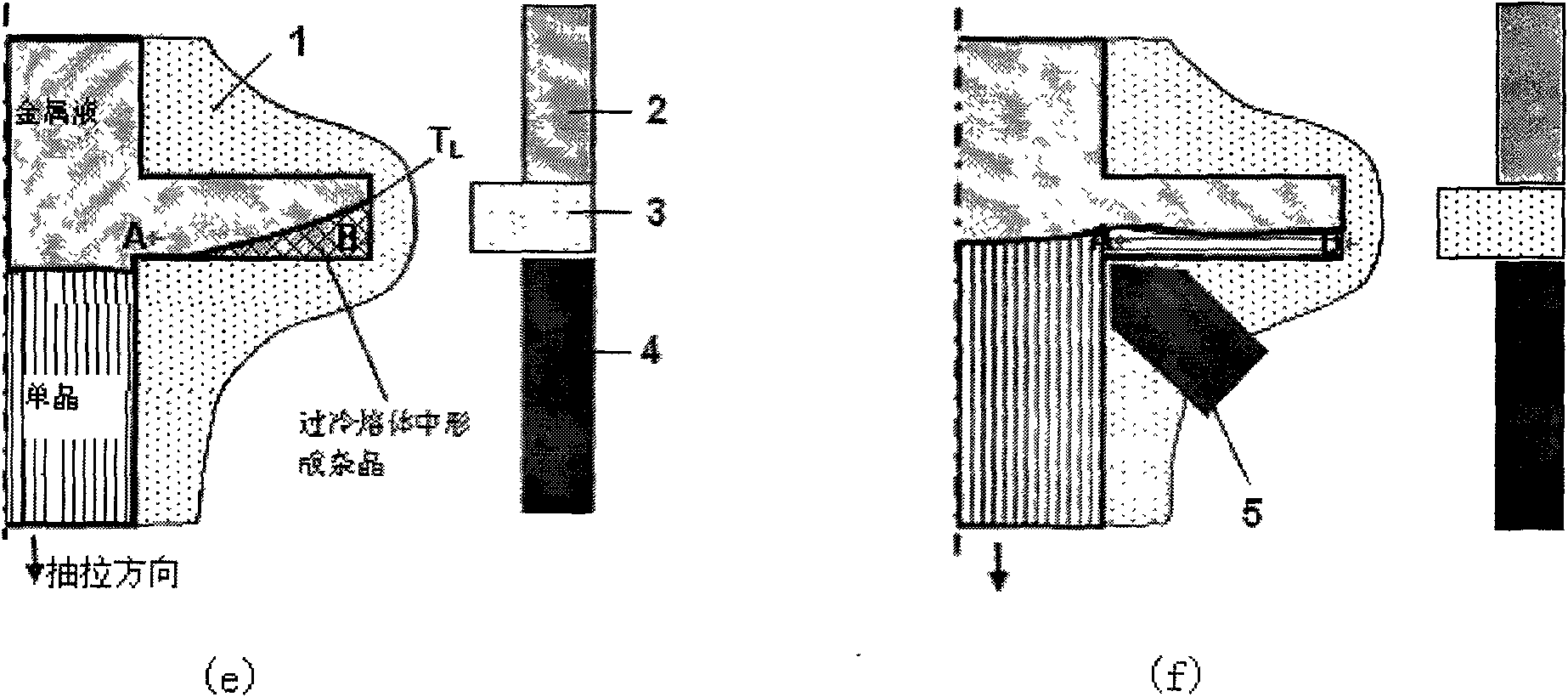

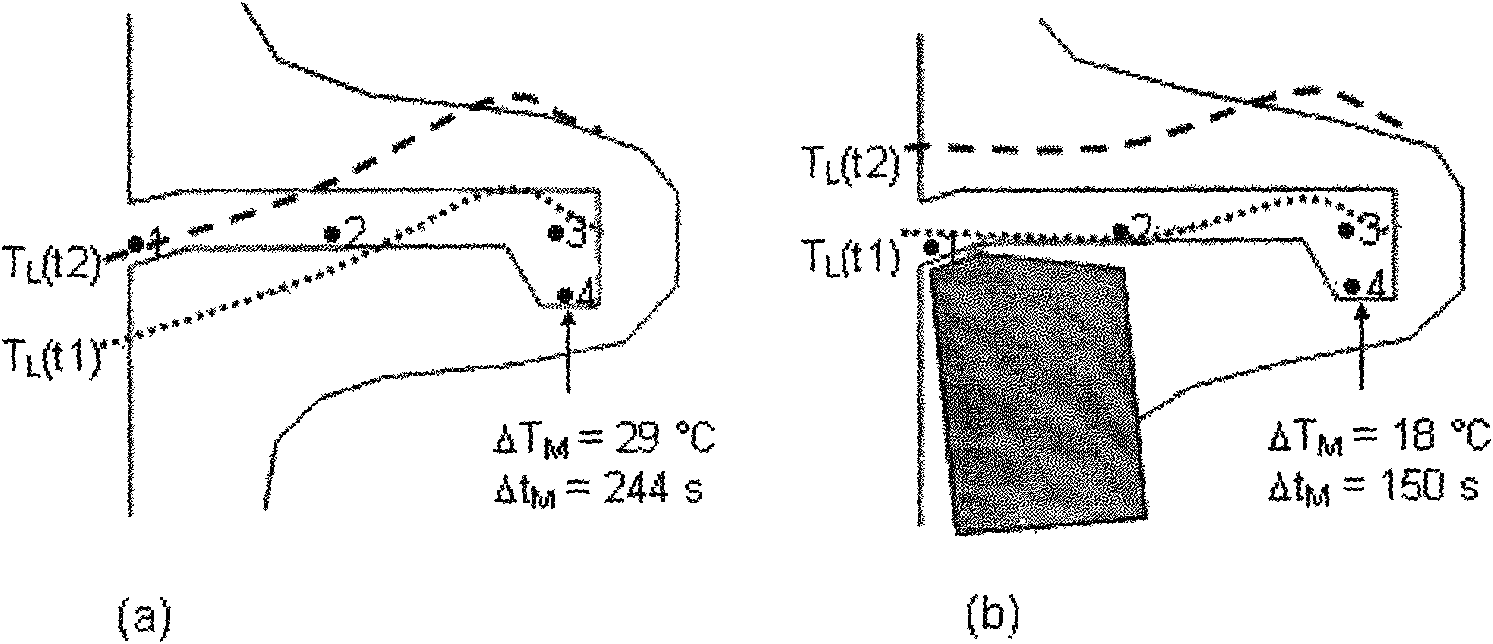

[0022] attached image 3 In the actual solidification process of the ceramic mold shell, T1=2105s and t2=2190s time T L - Isotherm distribution. Among them, the picture in (a) shows the T during the solidification process in the ceramic mold shell without implanting the thermal conductor. L -Isotherm; (b) The picture shows the T during the solidification process in the ceramic mold shell under the condition of implanting a heat conductor L -Isotherm. Obviously, the liquidus (T L ) isotherm due to the effect of thermal conductors, becomes obviously flat from concave. The degree of supercooling at the edge is reduced from 29°C to 18°C, and the supercooling time is reduced from 244 seconds to 150 seconds, which greatly reduces the possibility of formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com