Control method and device for continuous metal monocrystal casting process

A single crystal, metal technology, applied in the field of process parameters in the process of metal single crystal continuous casting, can solve problems such as process conditions that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

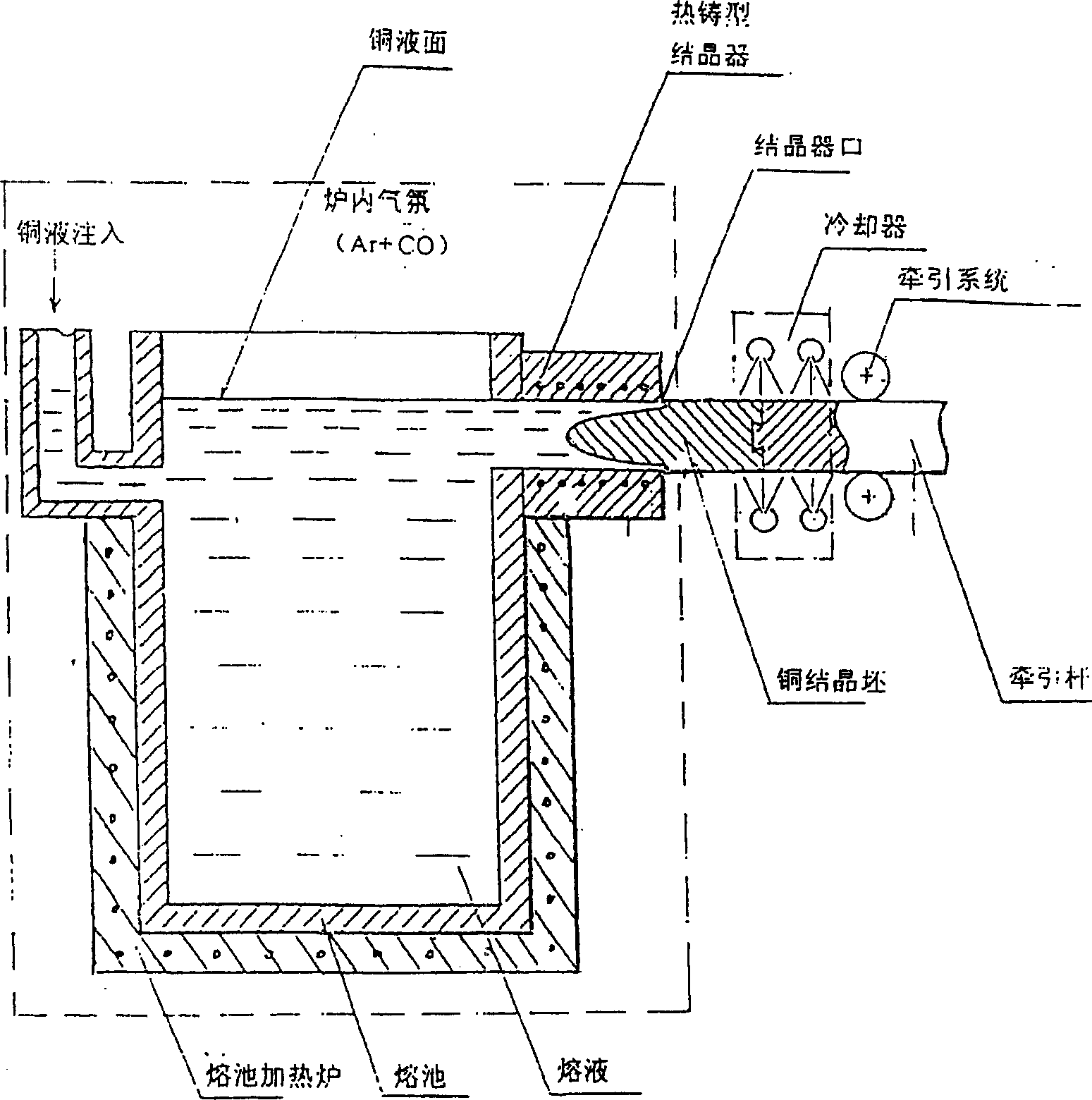

[0030] The structure of the complete horizontal directional solidification continuous casting device of one embodiment of the present invention is as follows: Figure 4 As shown, the device consists of three chambers separated by two vacuum isolation valves V1 and V2, namely the feeding chamber 1, the melting chamber 3 and the continuous casting chamber 5 and their cooling and pulling systems, and the configuration for each chamber Composed of pumping and argon filling system. The device realizes vacuum feeding intermittent smelting feeding and long-term continuous drawing casting.

[0031] The technical process of preparing single crystal copper by adopting the single crystal horizontal continuous casting device of the present invention is as follows Figure 5 shown. The present invention adopts vacuum feeding, vacuum intermediate frequency heating and smelting, liquid infusion in argon atmosphere, heat preservation and continuous casting, that is, the whole process of feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com