Return air gasification furnace with ring fire oven

A gasification furnace and fire roasting technology, which is applied to household stoves/stoves, washing devices, lighting and heating equipment, etc., can solve the problems of high tabletop temperature, clogging of furnace ash, and small furnace diameter, etc., and achieves convenient and economical use. The effect of fuel, ignition convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

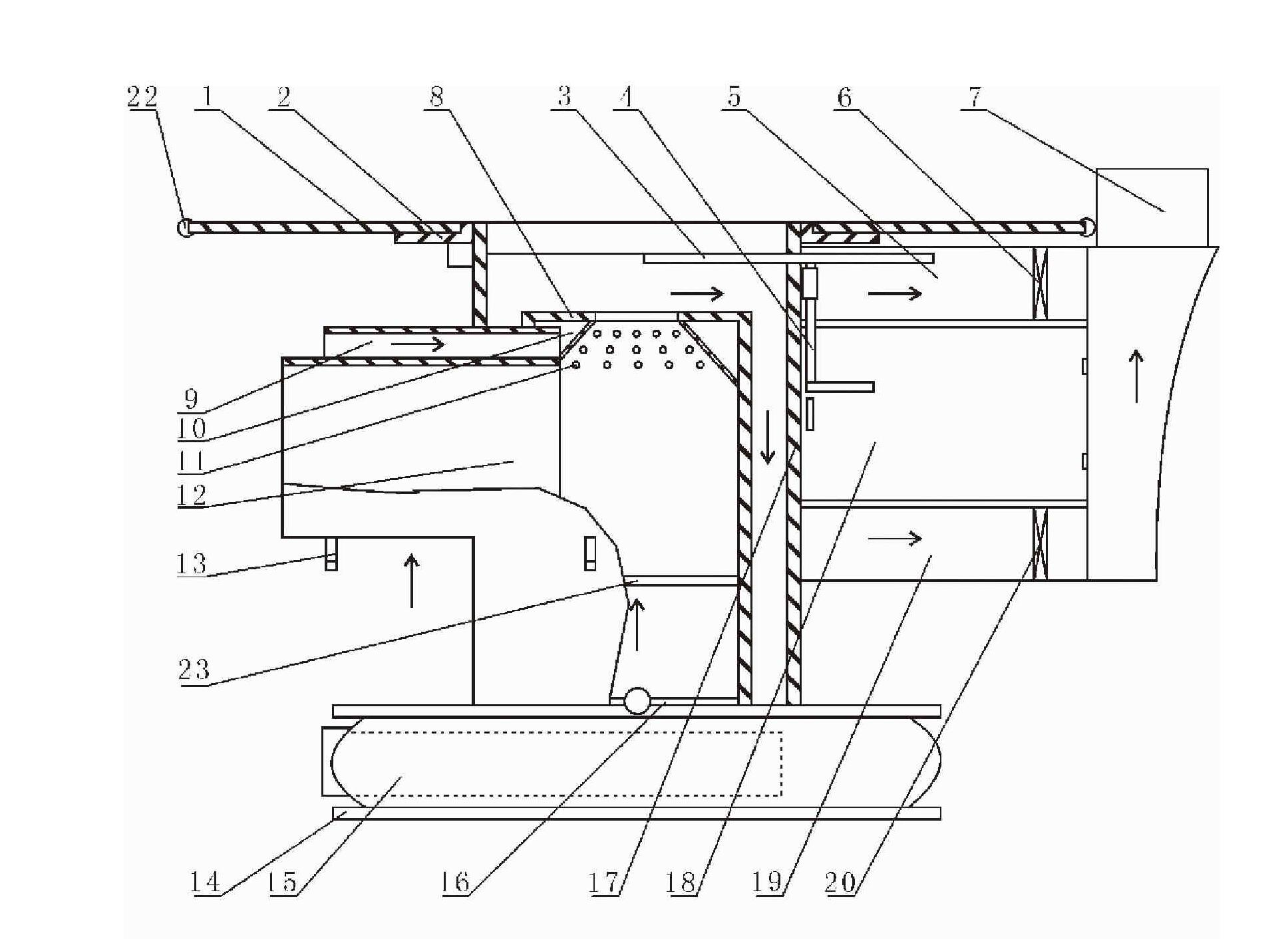

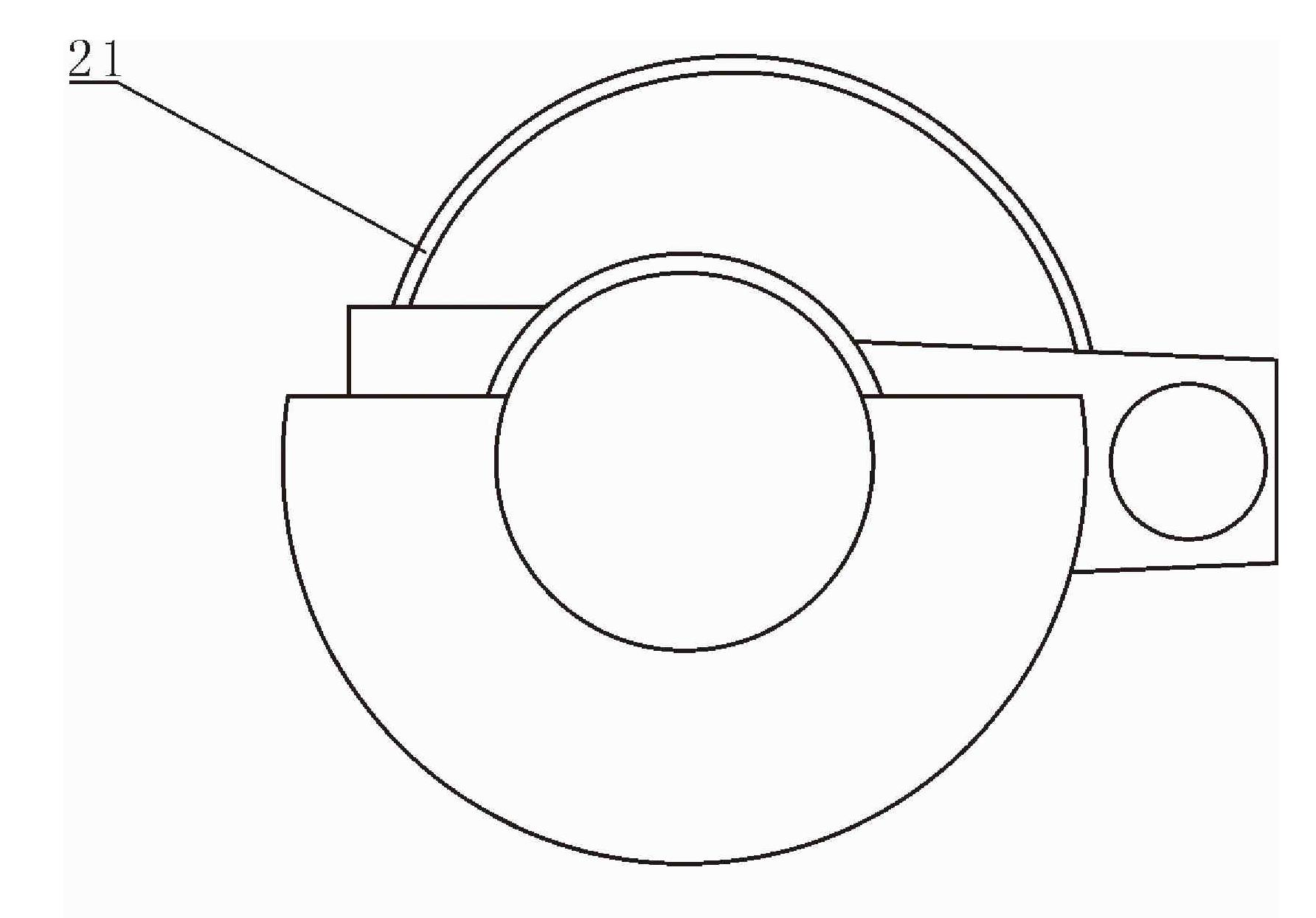

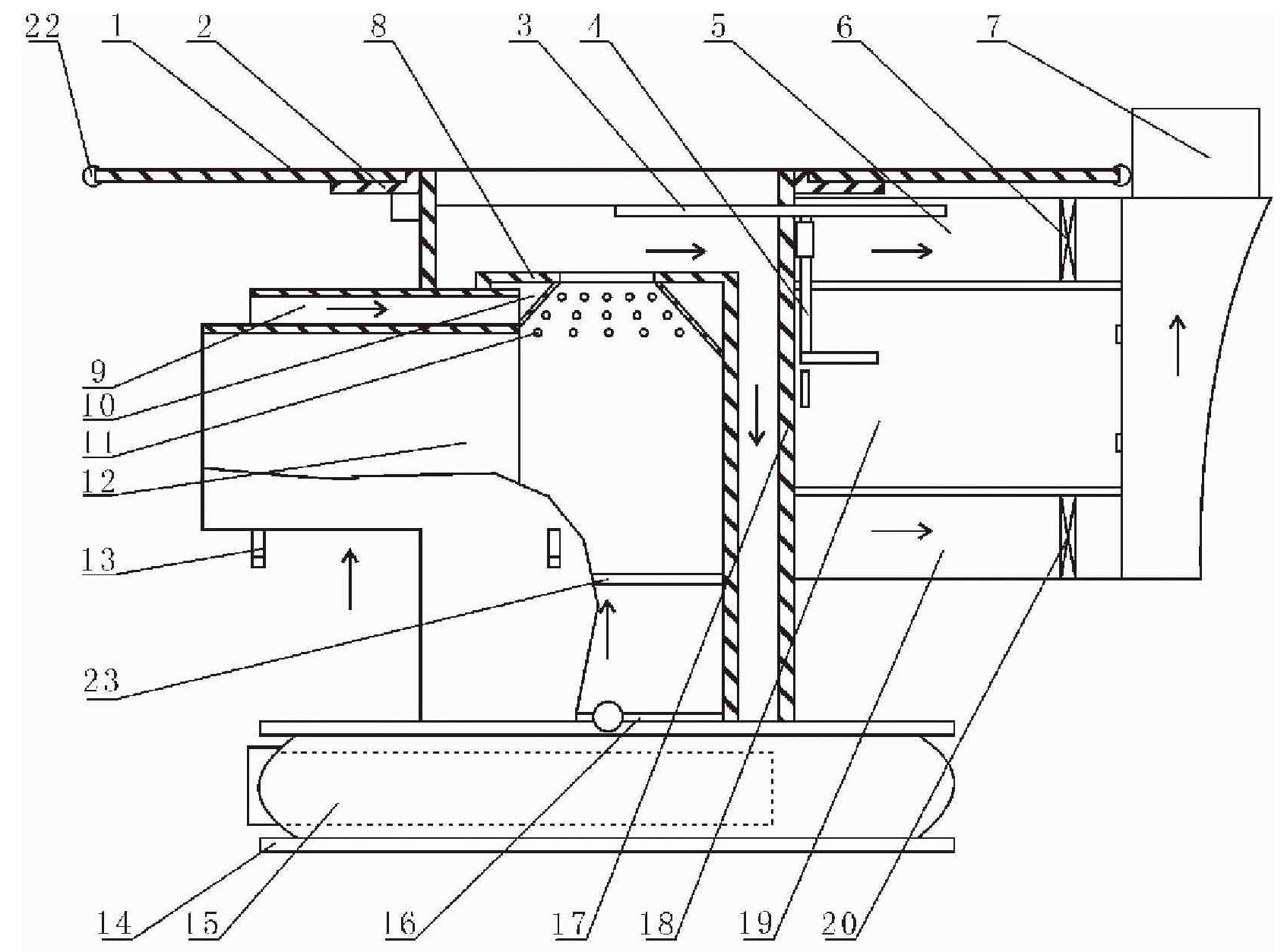

[0014] Such as figure 1 , figure 2 Among them, a return air gasification furnace with a ring fire oven includes a base 14, an ash hopper 15 is installed in the base 14, an ash discharge switch 16 is provided between the base 14 and the furnace body 17, and the furnace 8 is installed in the furnace body 17 The feed port 12 passes through the furnace body 17 to communicate with the furnace 8, and the furnace 8 is provided with a secondary air intake cavity 10, and the secondary air intake cavity 10 is provided with a secondary air intake hole 11 near the inner wall of the furnace 8, and the feed port 12 The two sides are provided with secondary air intake channels 9, and the secondary air intake channels 9 pass through the furnace body 17 to communicate with the secondary air intake chamber 10, and the secondary air intake chamber 10 is arranged on the upper part of the furnace 8. This scheme makes the furnace bridge The path at 23 is not affected by the secondary air intake c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com