Color film substrate and manufacture method thereof

A technology of a color film substrate and a manufacturing method, which is applied in the field of display devices and its manufacturing, can solve the problems of increased LCD thickness and cost, and achieve the effects of avoiding increased thickness, preventing glare, and improving clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

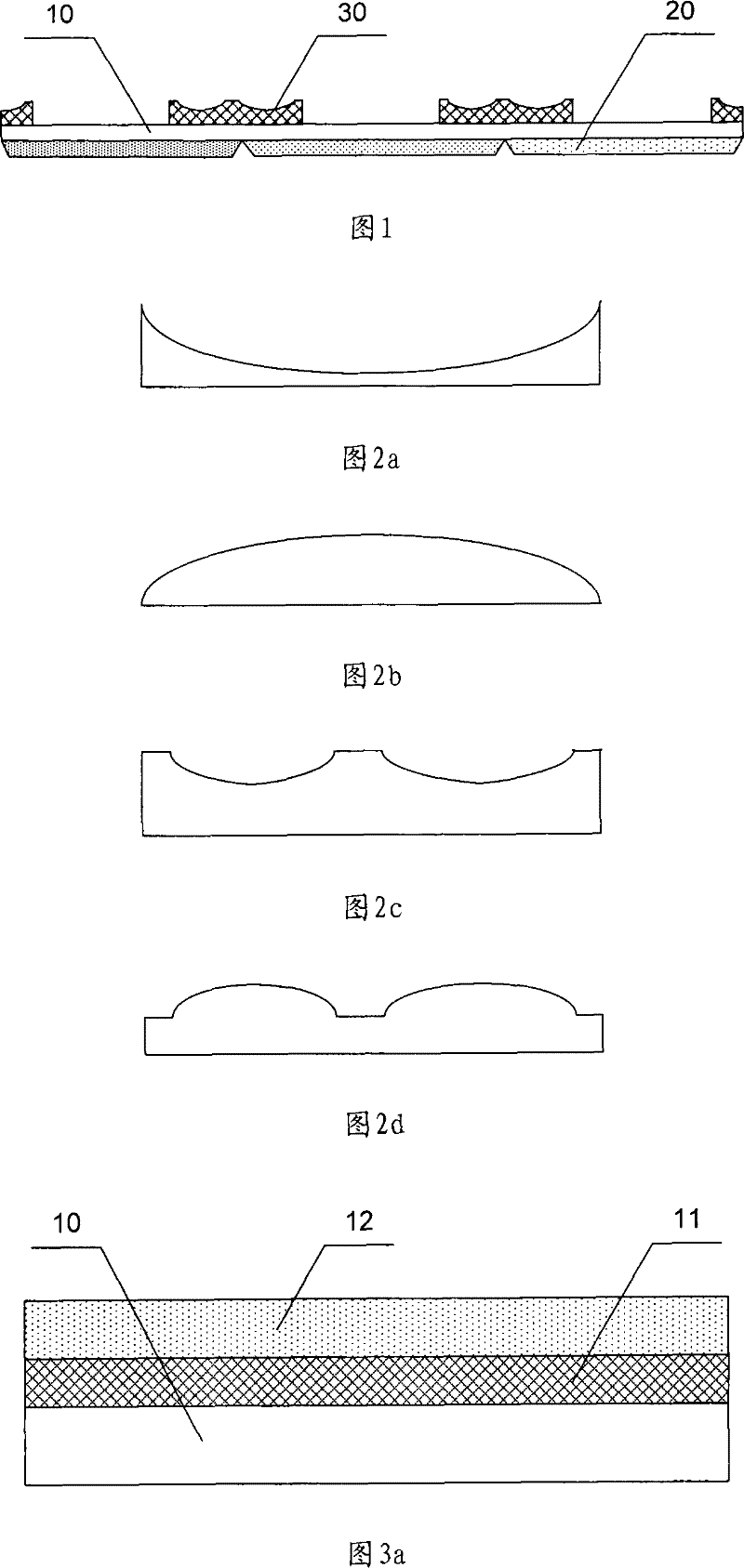

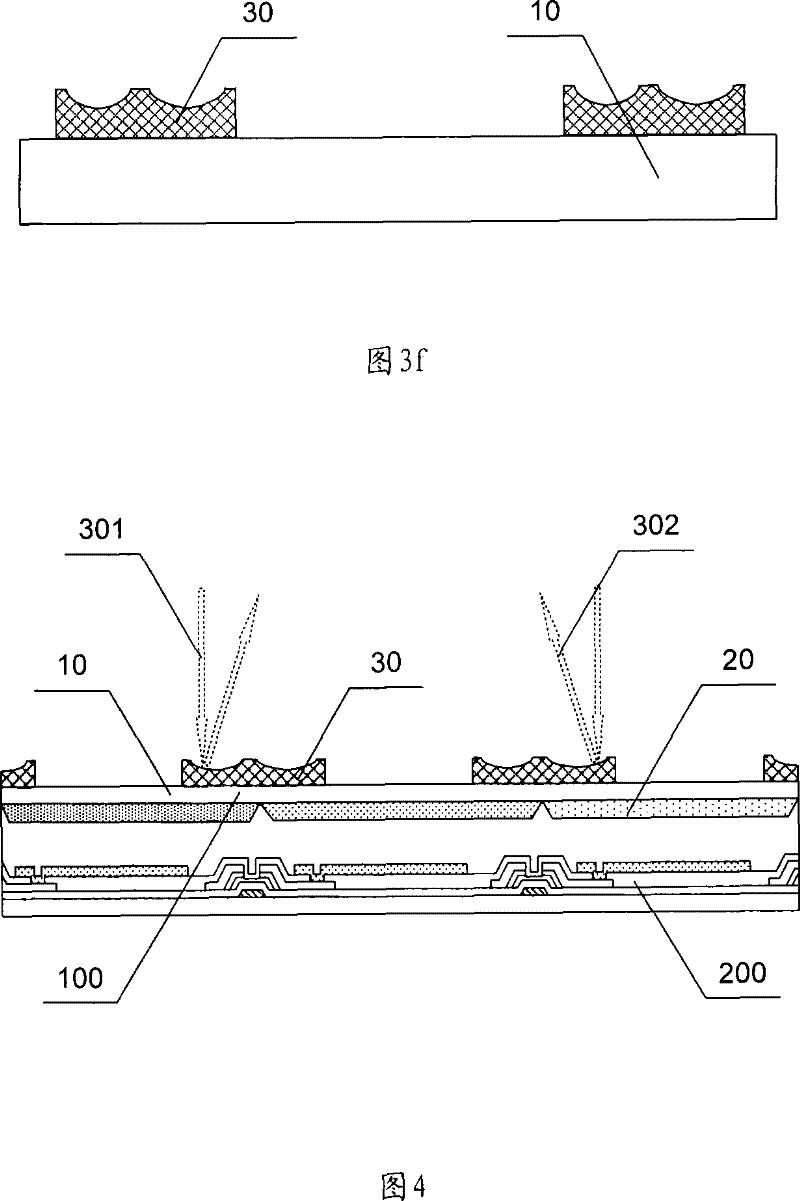

[0035] FIG. 1 is a schematic structural diagram of a color filter substrate of the present invention. As shown in FIG. 1 , the color filter substrate of the present invention is used to form an LCD (liquid crystal display device) in a box with an array substrate. The color filter substrate includes a substrate 10 and a color filter layer 20 and a black matrix 30 respectively arranged on both sides of the substrate 10. The color filter layer 20 is formed on the inner surface of the substrate facing the side of the array substrate, and the black matrix 30 is formed on the outer surface of the substrate facing the side of the incident light from the outside, and the black matrix 30 has the function of dispersing the incident light from the outside, so that the outside enters the outside of the LCD. The incident light forms diffuse reflection at the black matrix 30 to disperse the external incident light, thereby preventing glare, and improving visibility and picture clarity. At t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com