Conformance control through stimulus-responsive materials

A technology of flow control and flow, which is applied in the field of "spread control" and can solve problems such as not being disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

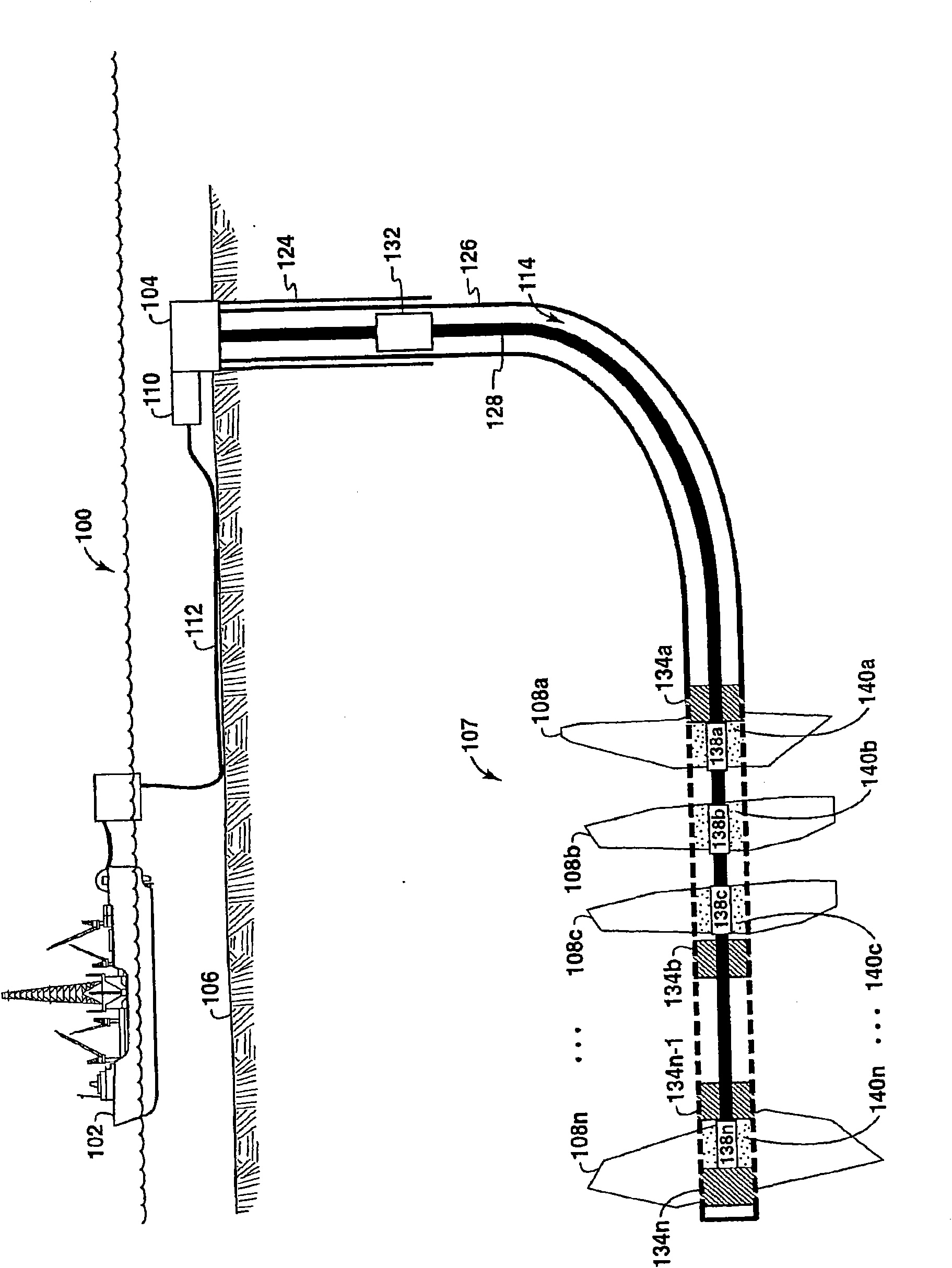

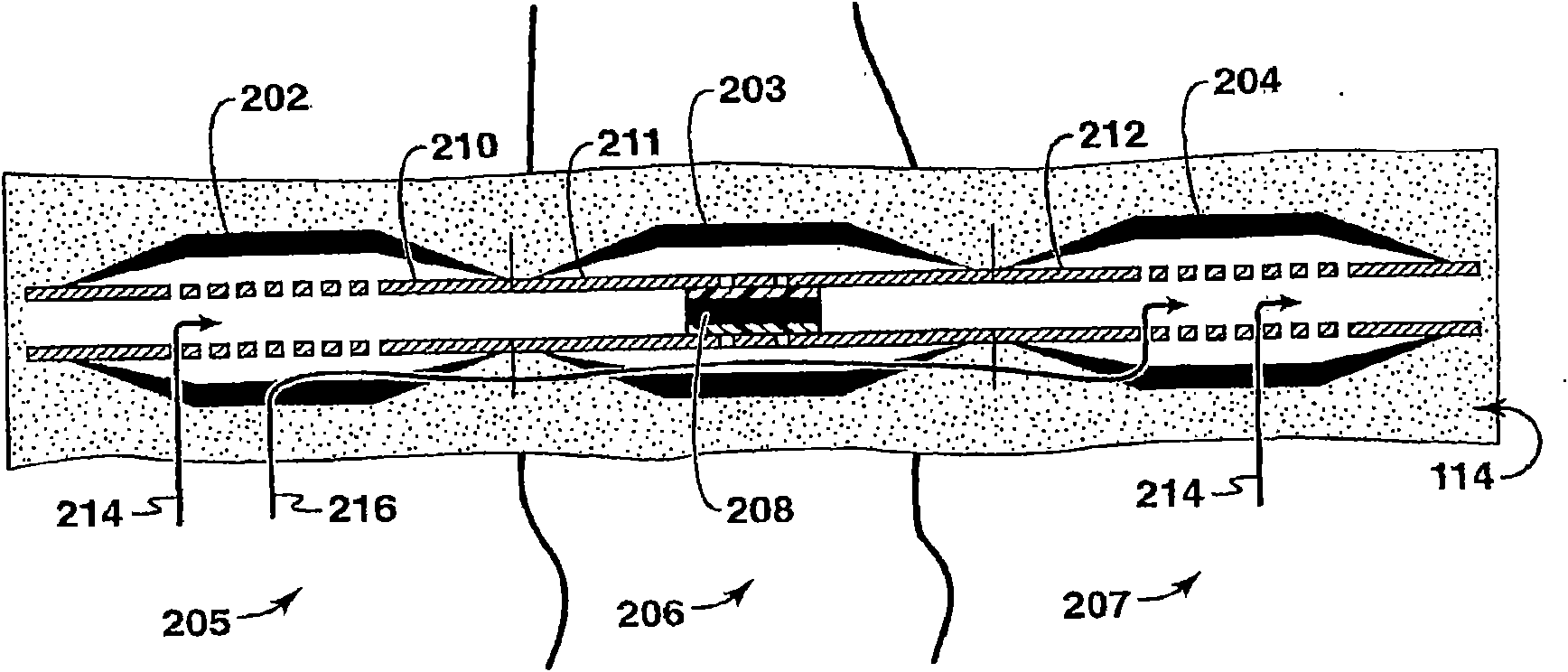

[0059] [0041] The exemplary embodiment is based on the concept of diverting the flow from "normal" radial flow with low pressure drop (from the surface of the drilled production zone, through the gravel pack, through the screen) to high pressure drop much more restrictive linear flow path through the screen outer annulus, which can be referred to Figure 7 was further explained. This embodiment requires a method of placing the sand face or casing-by-gravel packscreen annulus and gravel-packed screen-by-gravel packscreen annulus in the drilled production zone. packscreen-by-base pipe annulus) The flow path separation between the two. Blocking any of these annulus allows the use of plugs and / or straddle packers within the basepipe's inner diameter (ID) to control the production (or injection) profile. This method of blocking the flow path involves the use of consolidated sand composites (comprising a fraction of stimuli-responsive polymer beads or gravel coated with stimuli-re...

Embodiment 2

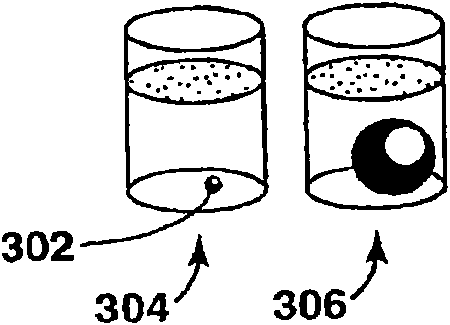

[0061] [0042] An alternative illustrative embodiment includes pumping a plurality of particulate solids, wherein a first portion comprises particles coated with a polymer that swells in the presence of formation water, and wherein a second portion comprises particles coated with "Shrink" the particles of the polymer. This "dual-action" gravel pack can increase permeability in oil-producing wellbore regions and decrease permeability in water-producing wellbore regions.

[0062] [0043] The exemplary embodiments described in Examples 1 and 2 may be used in any gravel pack application where the gravel is tightly packed and the gravel pack is substantially free of voids. Eliminating voids in gravel packs or adding excitation-responsive particles that swell in the presence of water eliminates unrestricted annular flow paths by ensuring flow is forced through low-permeability gravel packs. The flow velocity is then controlled by the length of the flow path, the permeability of the g...

Embodiment 3

[0076] Example 3 : Natural sand filling (NSP)

[0077] [0053] In an alternative embodiment, the sand control screen may also be installed without a gravel pack. In these installations, over time, unconsolidated sand from the formation fills the annulus as the well produces. This technique can be used to control inflow profiles in a manner similar to that discussed above, as long as the natural sand fill has no voids between installation of exciter-responsive particles or materials according to the technique and intervals where profile control is beneficial.

[0078] B) Sealing of water or gas by well completion design: excitation-responsive coatings

[0079] [0054] In these embodiments, water or gas ingress is expected during well operation prior to completion installation. These embodiments may also be used for natural sand-pack completion types, open hole gravel-pack completion types, or cased hole gravel-pack completion types.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com