Roll feeder

A technology of feeder and roller type, which is applied in the field of roller feeder, can solve problems such as troublesome replacement operations, and achieve the effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, preferred embodiments of the present invention will be explained in detail with reference to the accompanying drawings.

[0042] A. The overall structure of the roller feeder

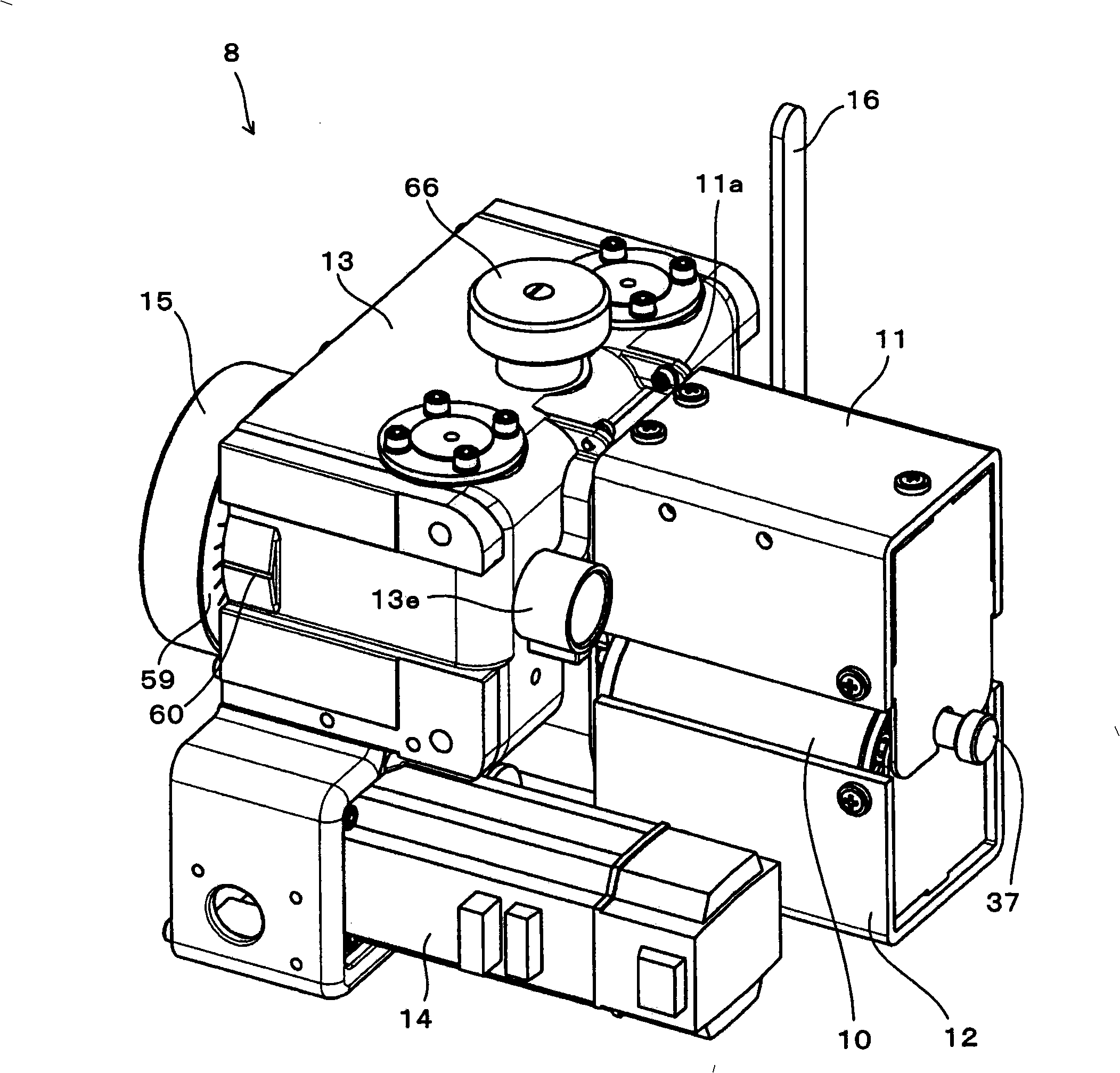

[0043] figure 1 is a perspective view showing the roller feeder 8 of the embodiment, with the covers 11 , 12 in the closed position (state where the covers 11 , 12 are in the closed position to be described).

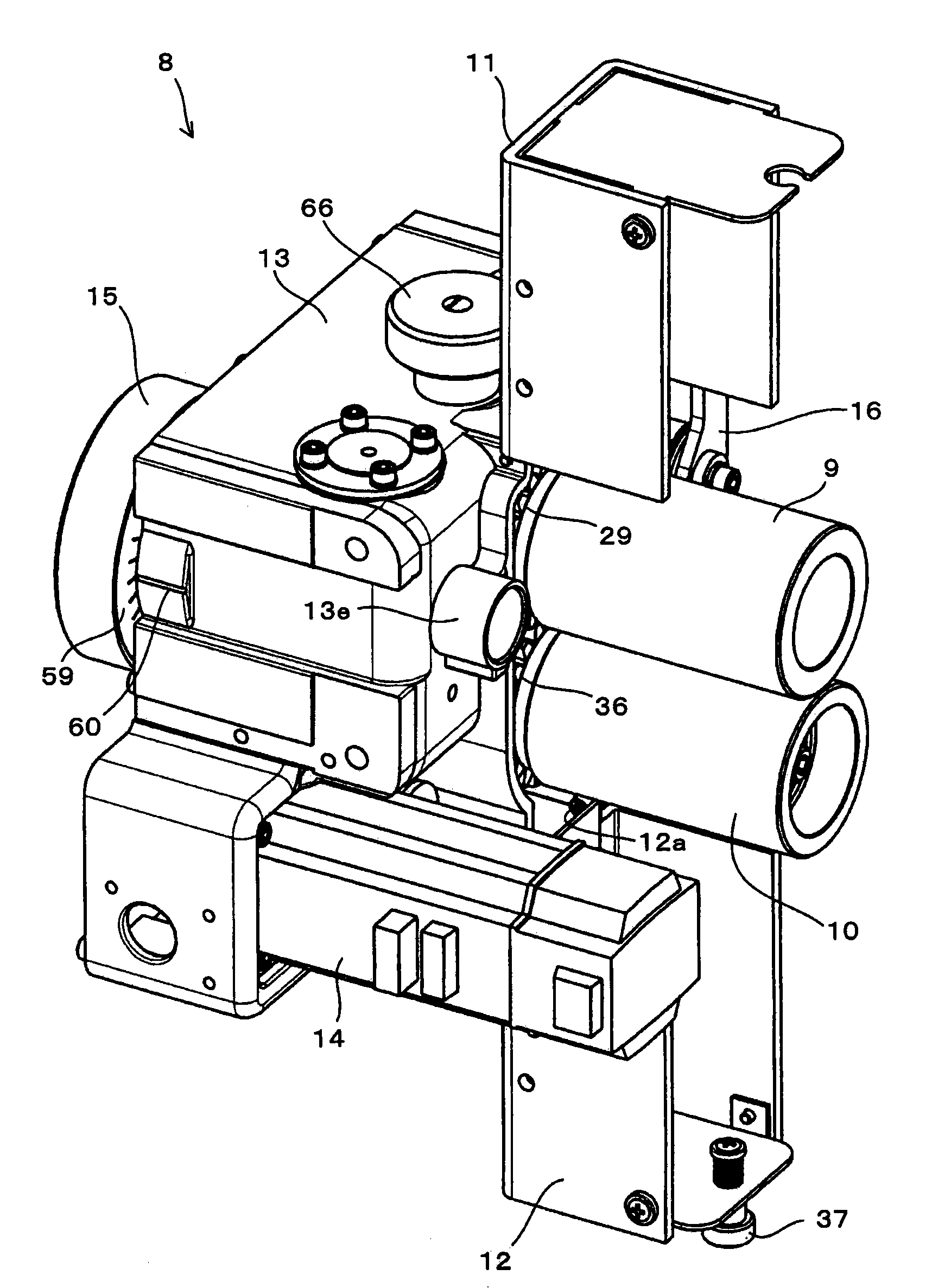

[0044] figure 2 is a perspective view showing the roller feeder 8 with the covers 11, 12 in the open position (the state where the covers 11, 12 are in the open position to be described).

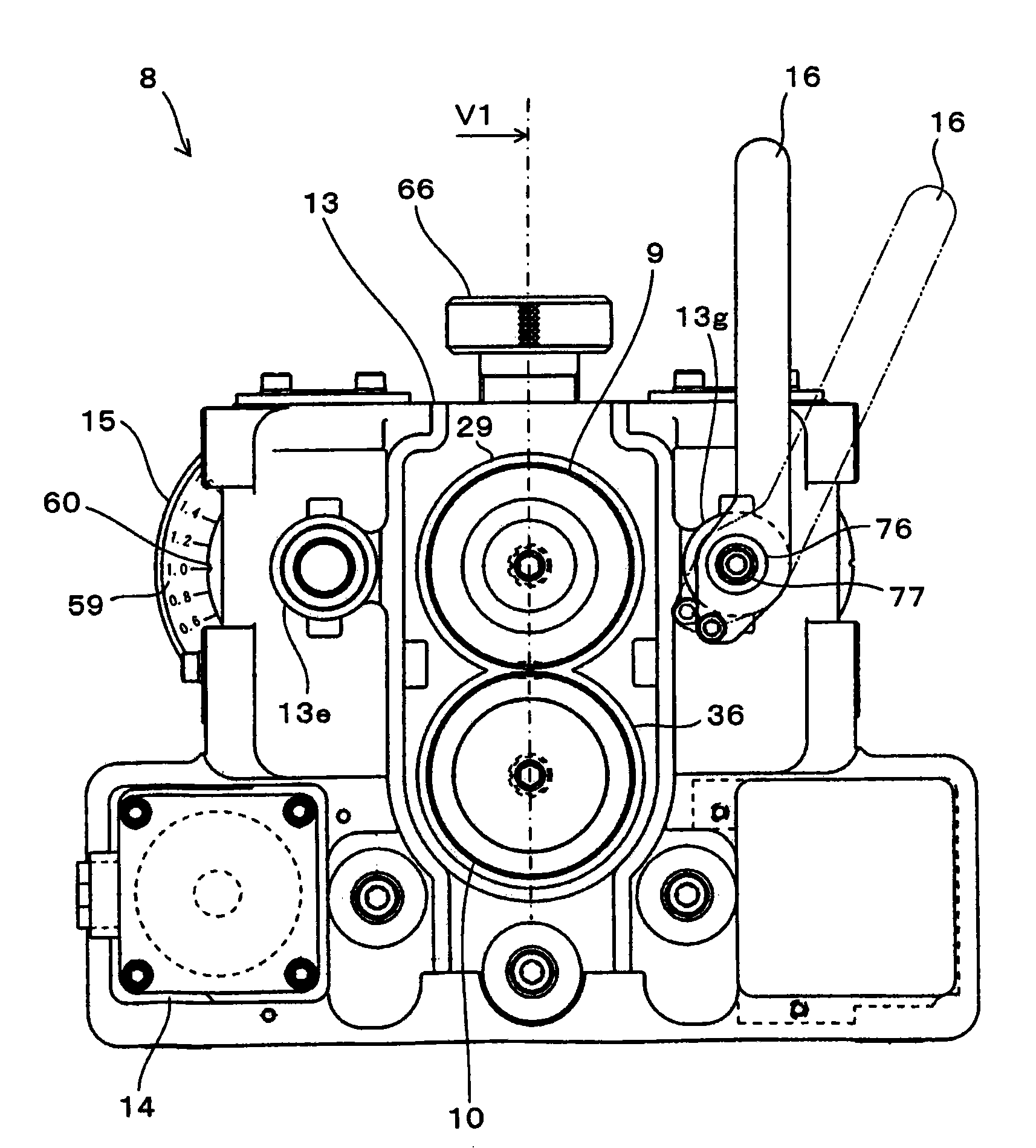

[0045] image 3 It is a front view of the roller feeder 8.

[0046] Figure 4 It is a rear view of the roller feeder 8. Figure 4 Showing that lid (lid) 17, handle 15, etc. have been removed ( Figure 7 shown in ), which will be described later.

[0047] Figure 5 It is a right side view of the roller feeder 8.

[0048] Figure 6A is a vertical section view of the roller feeder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com