A frequency and speed modulating multi-ring oil mill

An oil press and speed regulation technology, which is applied in the field of presses, can solve the problems of insufficient oil yield, high manufacturing cost, and non-durability, and achieve the effects of high oil yield, long service life, and improved use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

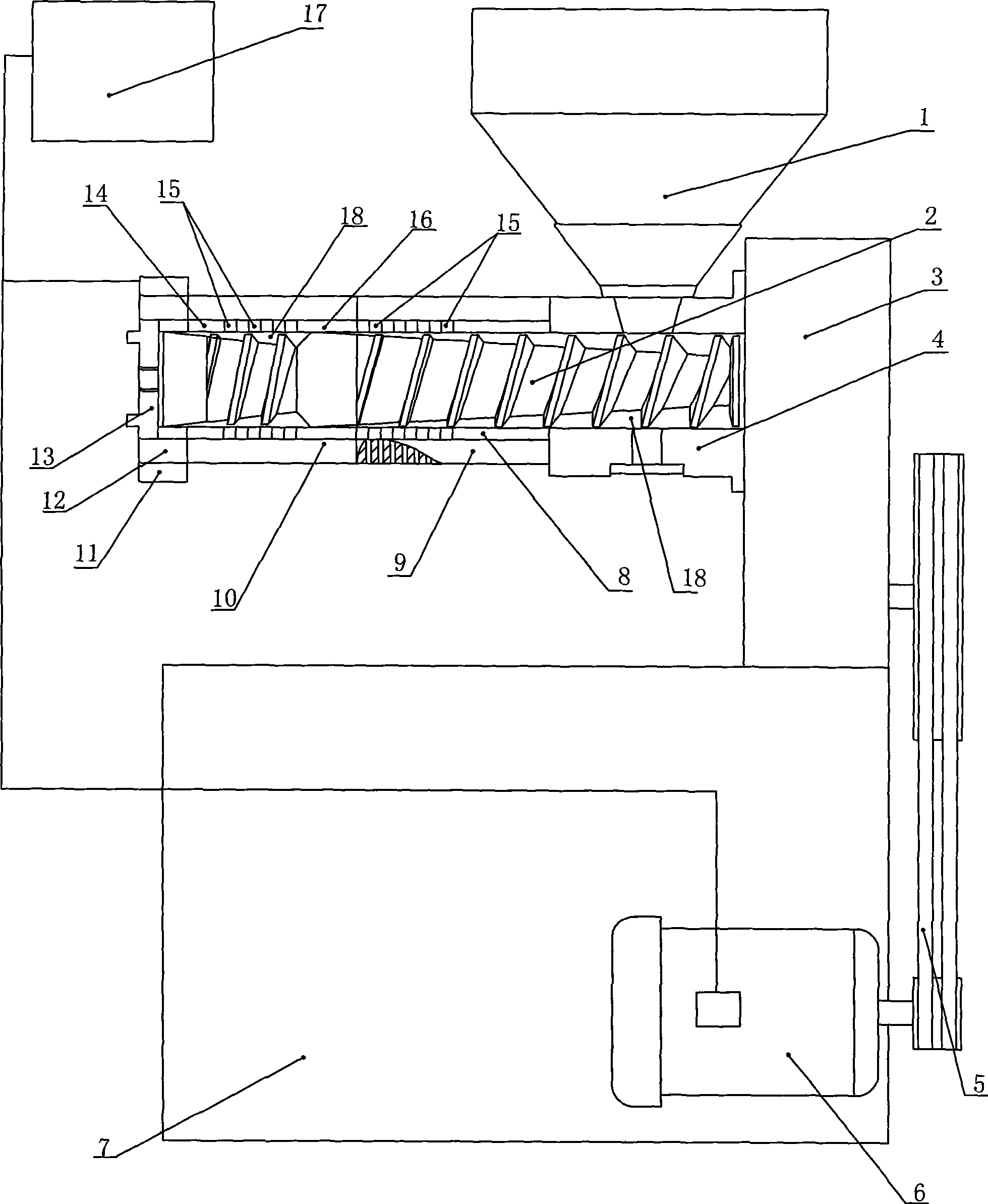

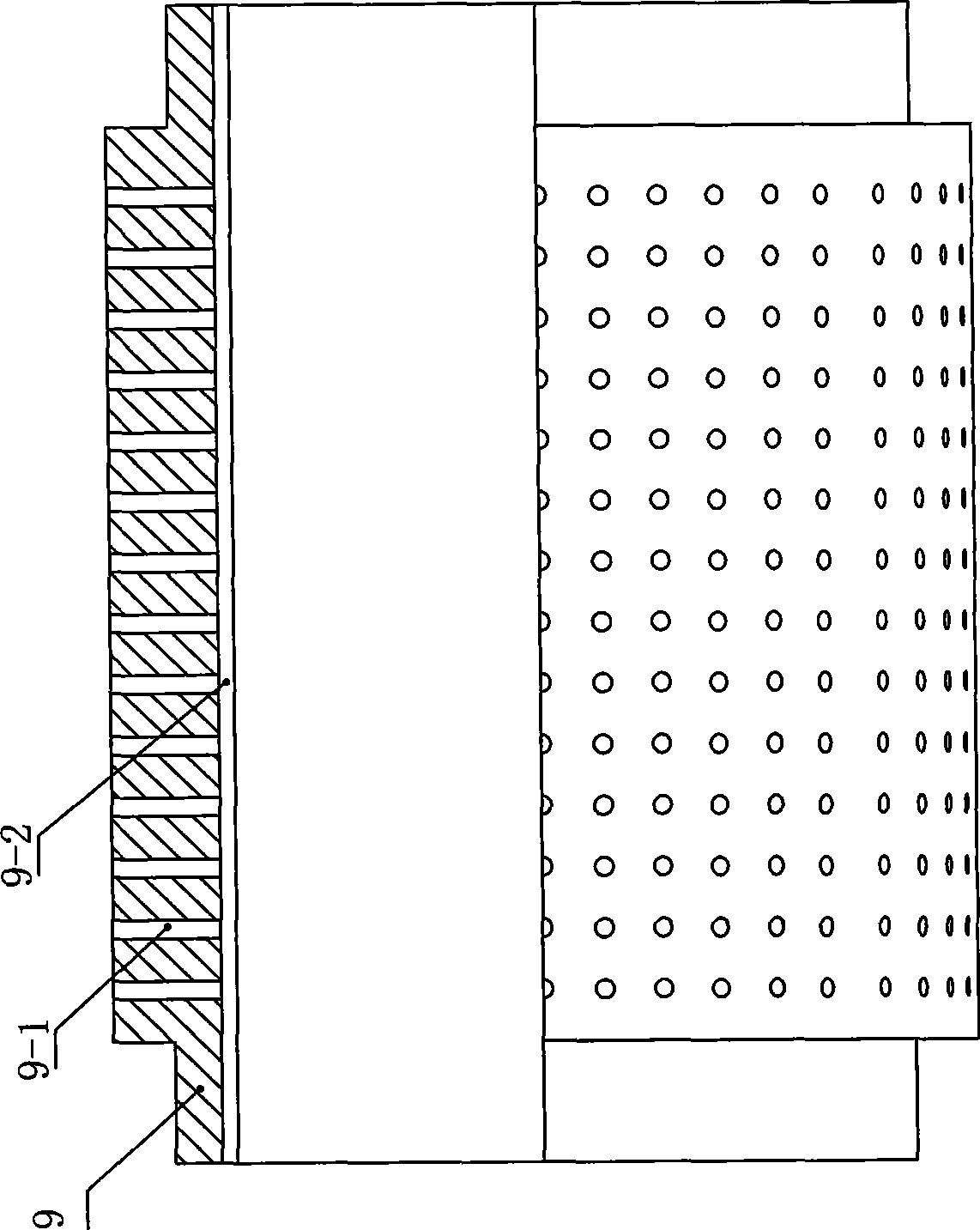

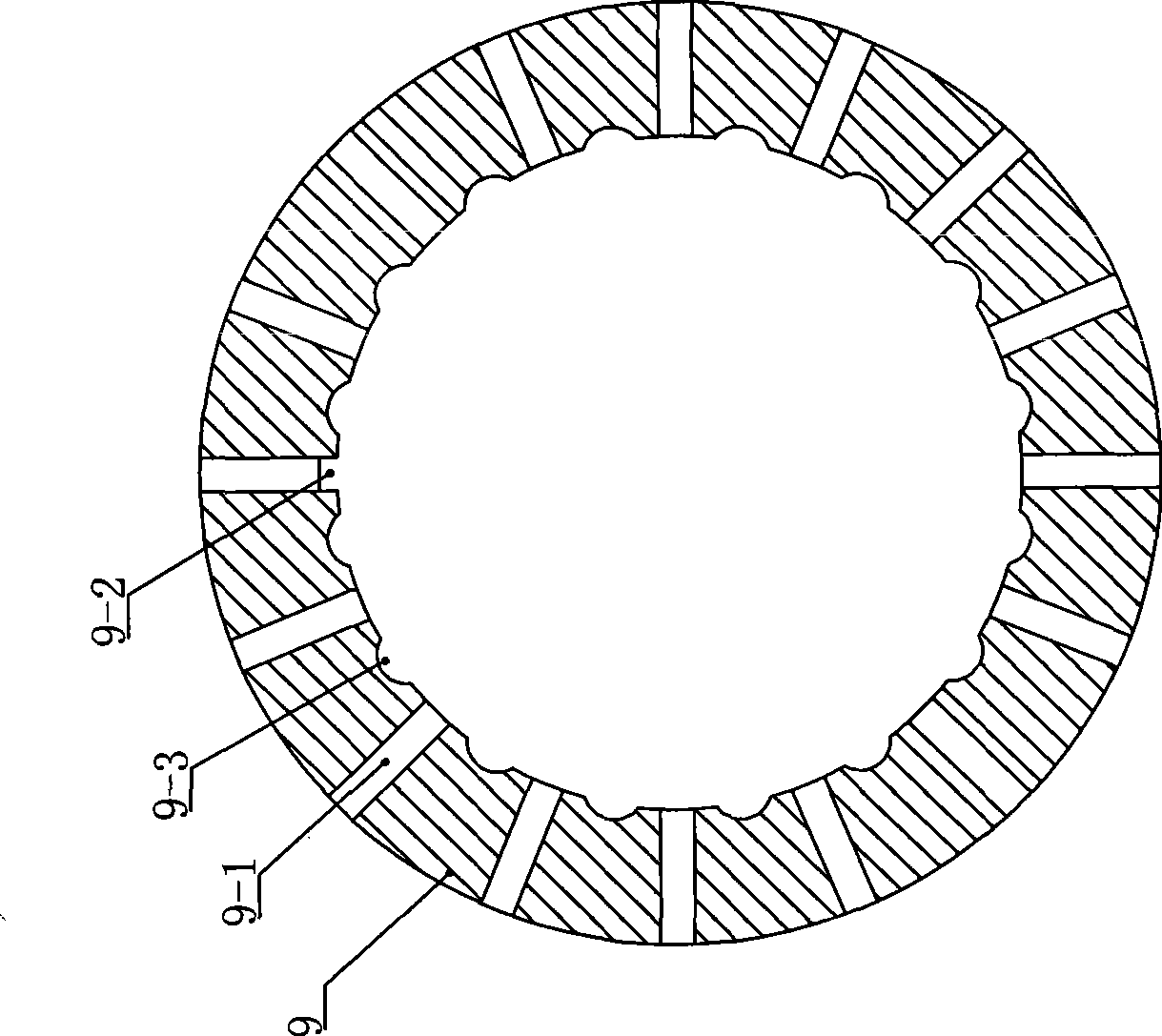

[0024] Embodiment: see specification attached Figure 1-Figure 7 , in the figure 1-Lower hopper, 2-Screw screw, 3-Gear box, 4-Load section, 5-Belt, 6-Electric motor, 7-Body, 8-Integral row, 9-Primary shell, 10-secondary pressing shell, 11-split bearing pad heating plate, 12-retaining ring, 13-slag outlet parts, 14-secondary pressing ring, 15-oil ring, 16-first-level pressing ring, 17-electric Control box, 18-squeezing chamber. In the figure, a multi-ring oil press with frequency modulation and speed regulation includes a body 7 and a press body installed on the body 7, a gearbox 3, and an electrical control box 17. The gearbox 3 is connected to the motor 6 through a belt 5, The press body includes a press chamber part and a press snail part, and the press chamber part is sequentially composed of four sections: the feeding opening section 4, the first shell pressing section, the second shell pressing section, and the slag outlet section; The lower hopper 1 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com