Large steam turbine-generator set rotor crack fault real-time diagnosis method

A technology for steam turbine generator sets and rotor cracks, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of long cycle time and high economic cost of diagnosis, and achieve scientific methods and reliable conclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

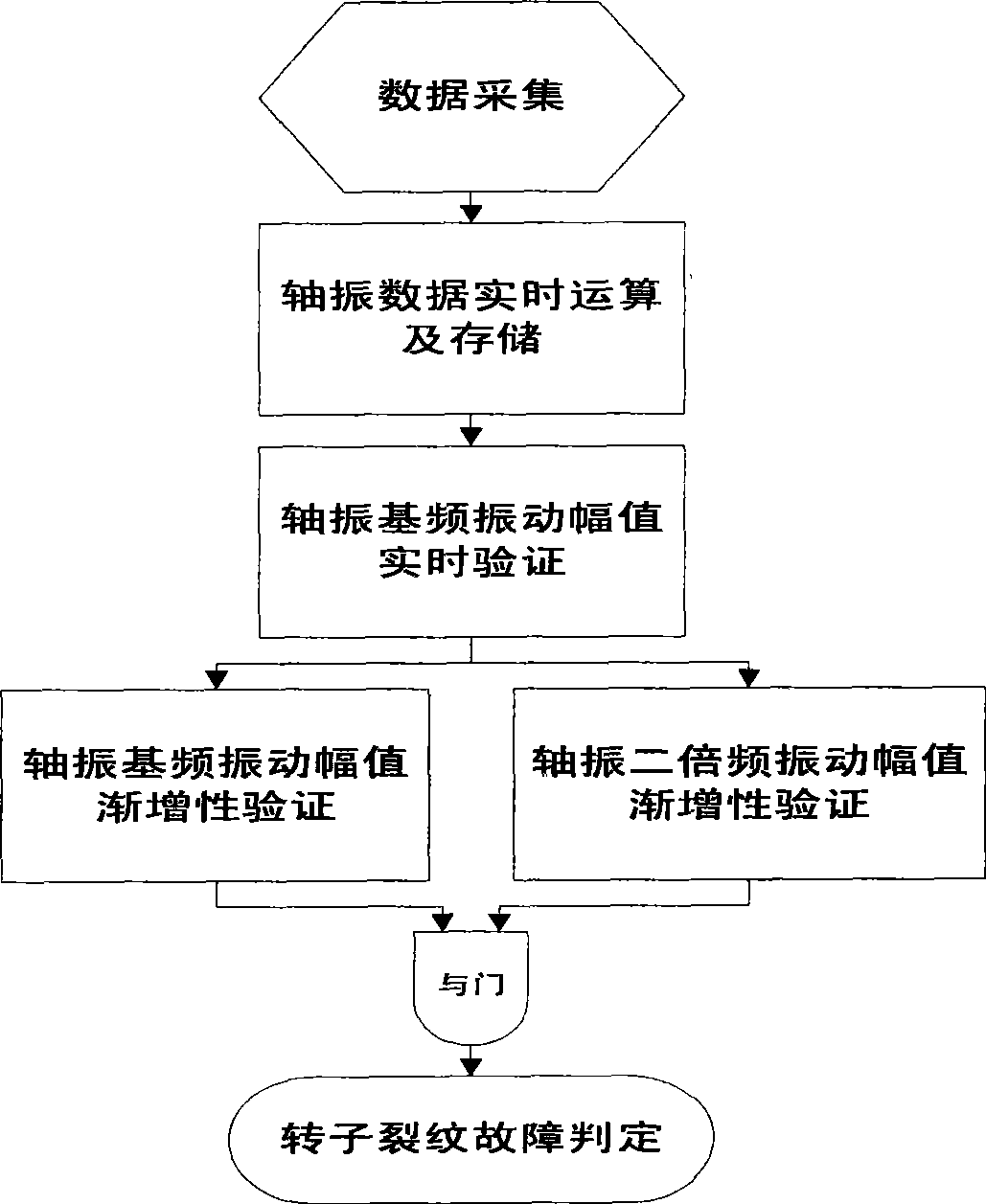

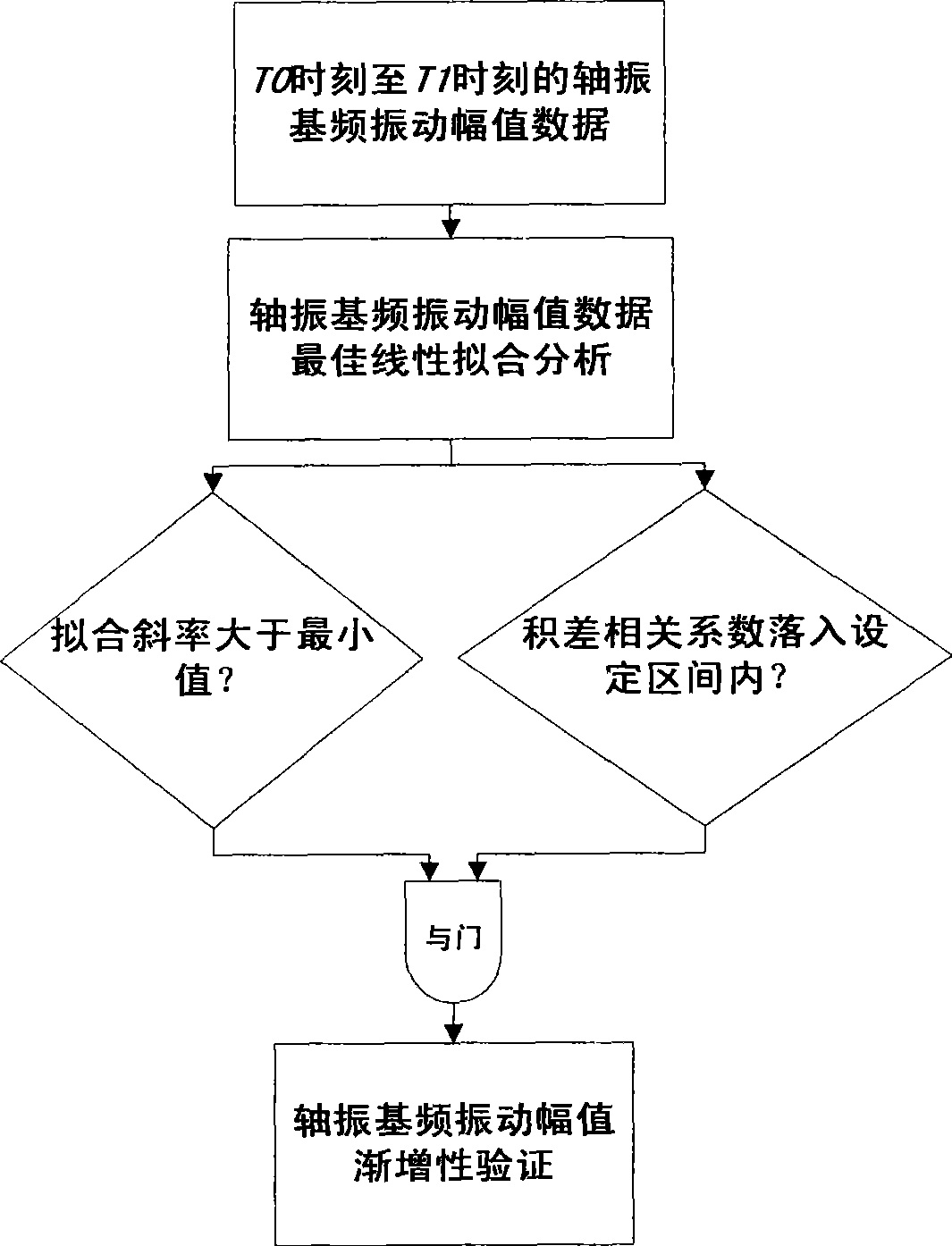

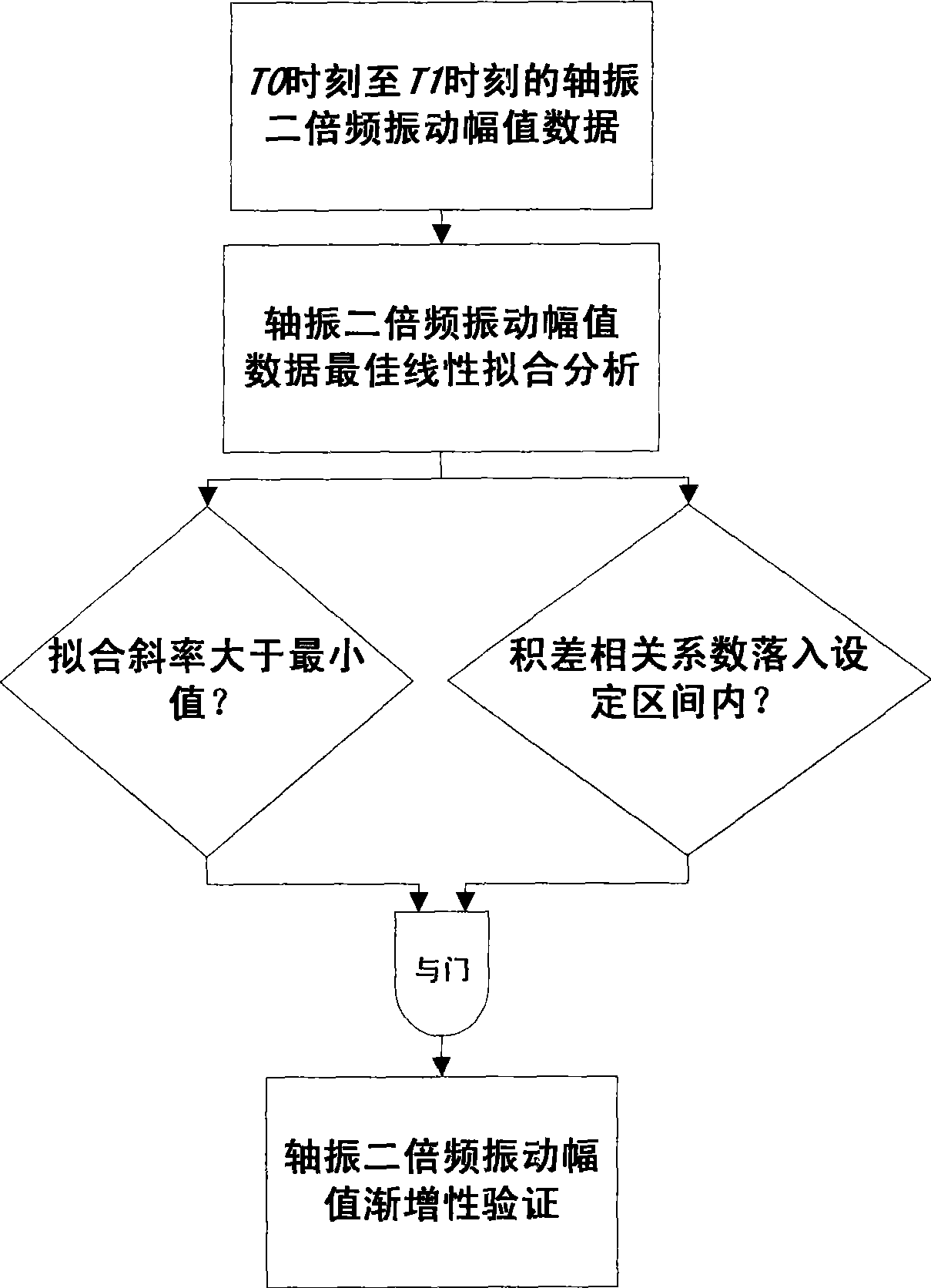

[0037] The method can be used to realize real-time monitoring, analysis and diagnosis of the rotor crack fault of the turbogenerator. The shaft vibration signal of the turbogenerator set required by the diagnosis method and the key phase signal required for the analysis and processing of the vibration signal can be obtained from the monitoring instrument (TSI) equipped with the turbogenerator set or from professional vibration data acquisition and conditioning equipment. In this embodiment, the shaft vibration signal of the steam turbine generator set and the key-phase signal required for the analysis and processing of the vibration signal are obtained from professional vibration data acquisition and conditioning equipment connected to the vibration sensor. exist Figure 4 In the schematic diagram of monitoring the crack fault of the rotor of the steam turbine generator set shown, the high-speed data acquisition card is inserted into the slot provided by the industrial microco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com