Enhanced silk protein material having improved mechanical performance and method of forming the same.

A technology of mechanical properties and proteins, applied in the field of protein materials, can solve problems such as not much progress recorded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

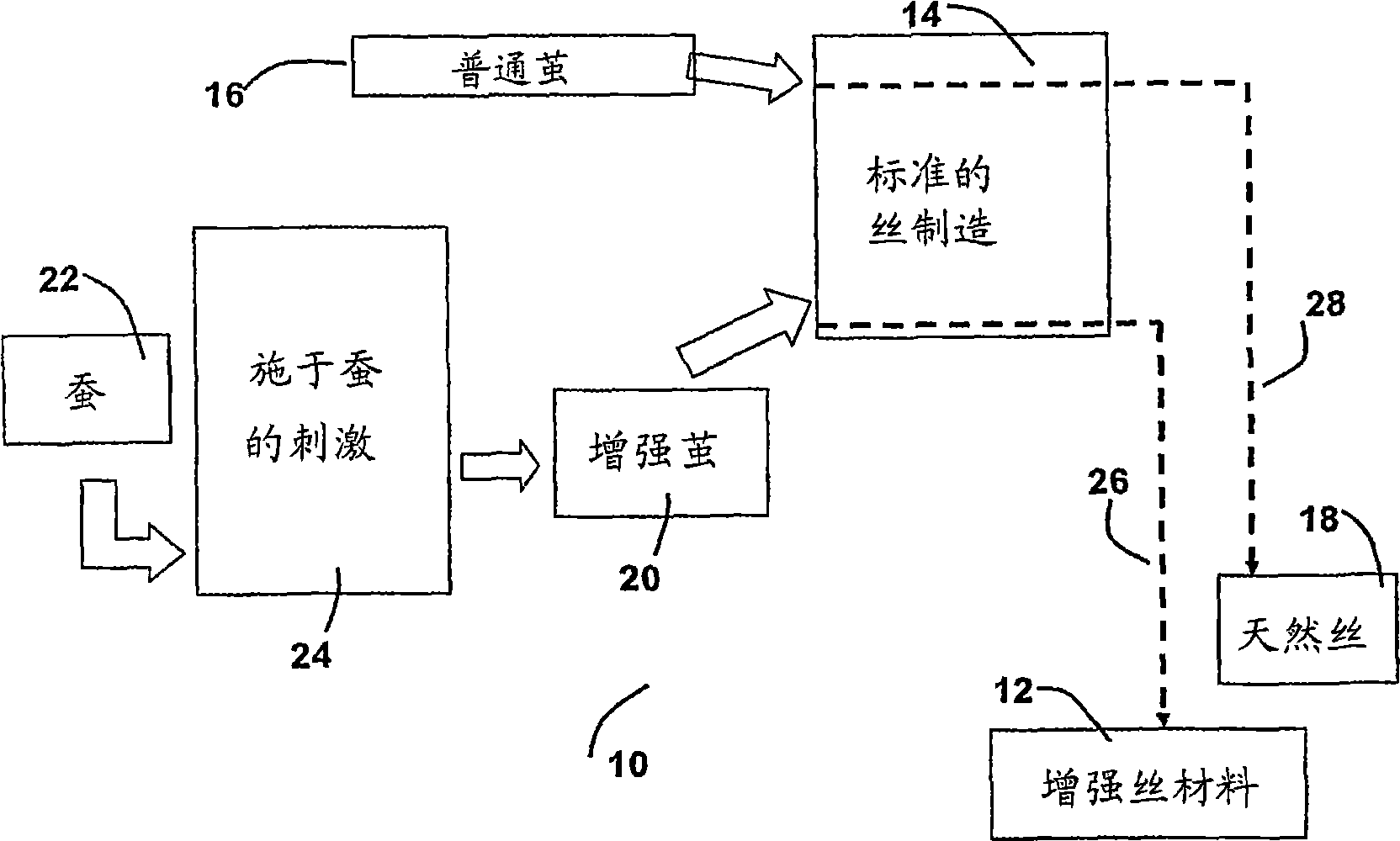

[0072] figure 2 Shows how a manufacturing process 10 of a reinforced protein material which is silk fiber 12 can be inserted into a standard manufacturing process 14 of a common cocoon 16 , meaning a cocoon comprising natural silk 18 , in a conventional and cost-effective manner. The silkworm 22 is stimulated 24 in order to produce the reinforced protein material 12 . The resulting reinforced cocoon 20 comprising the reinforcing protein material 12 is processed using the same standard manufacturing process 14 as the normal cocoon 16 comprising natural silk 18 . Thus, upon completion of the same standard manufacturing process 14 that is used to conventionally manufacture 28 natural silk 18 , a reinforced protein material 12 is obtained 26 .

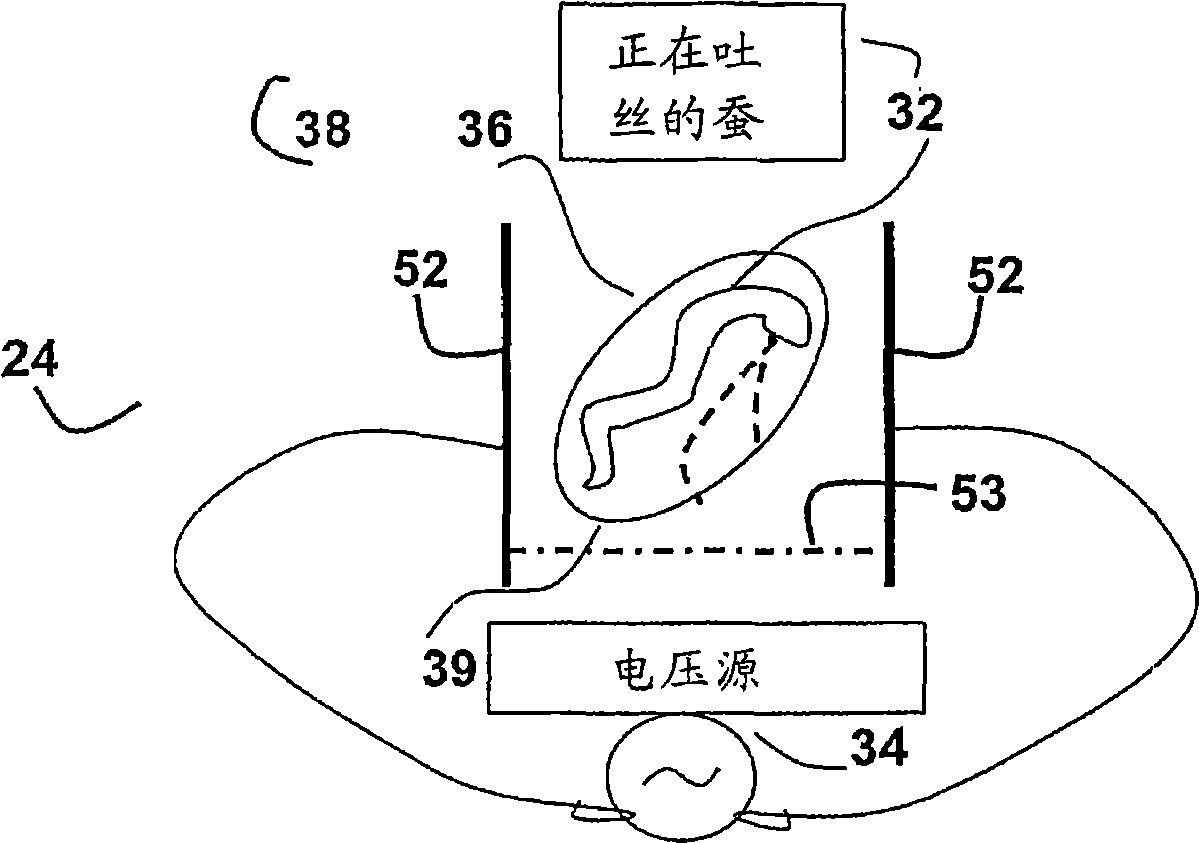

[0073] image 3 The effect of stimulus 24 on silkworm 32 in this embodiment is illustrated. A silkworm 32 is placed in a compartment 36 belonging to a compartment array 38 . Stimulus 24 , in this embodiment an electric field ass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com