Hot cathode fluorescent lamp

A fluorescent lamp and hot cathode technology, applied in discharge lamps, gas discharge lamps, electrical components, etc., can solve the problems of shortened lamp life, rapid loss of electron emission materials, short circuit, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

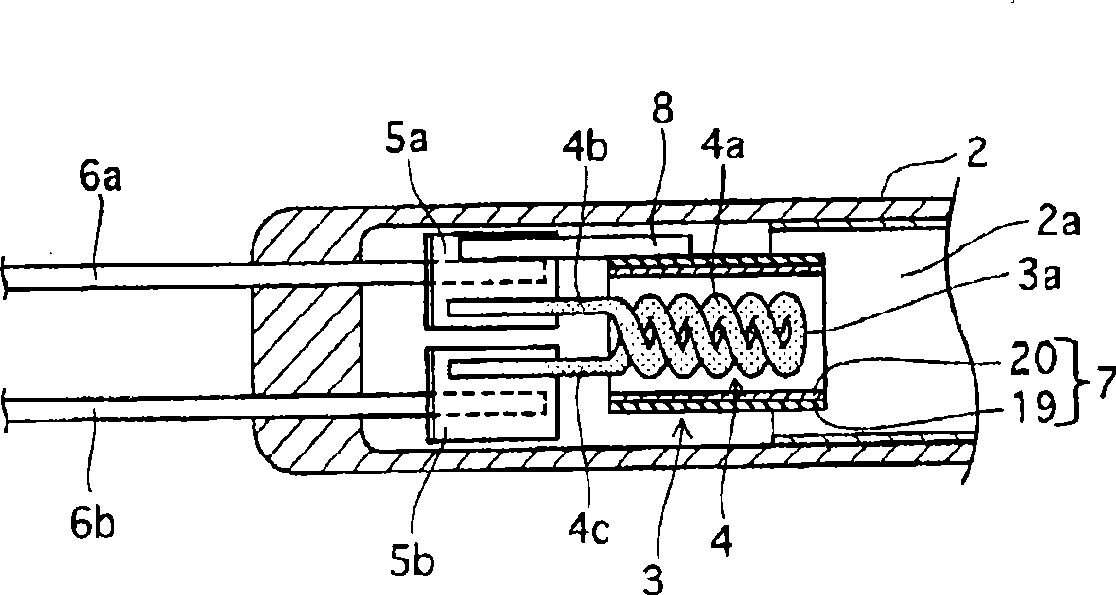

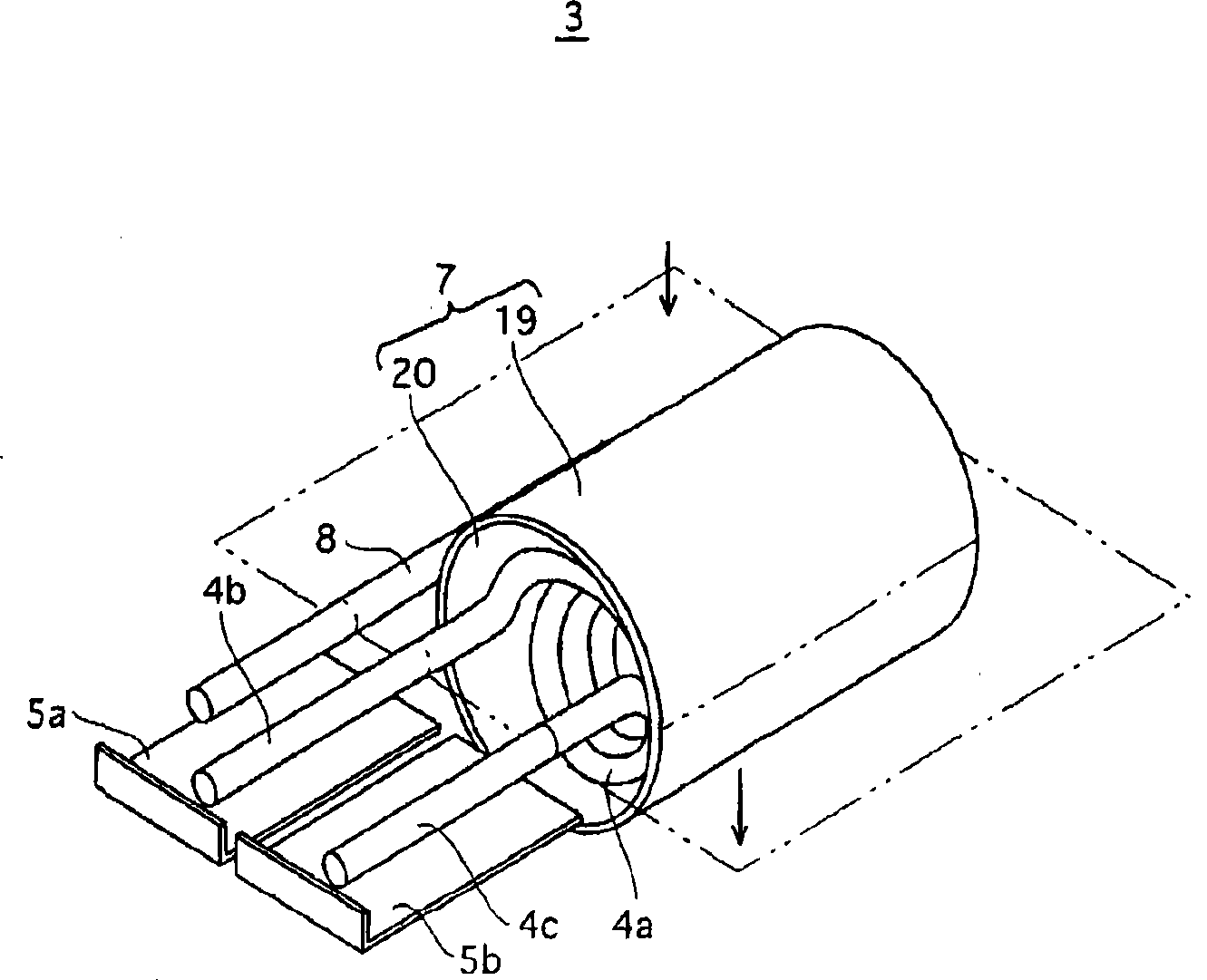

[0065] As shown in FIG. 3( b ), the insulating film 21 of Modification 1 is thicker on the side of the first lead portion 4 b and the second lead portion 4 c than on the side of the folded end of the winding portion 4 a.

[0066] For example, in the insulating film 21, the thickness t2 of the opening end of the substrate 19 on the side of the folded end is set to 0.05 mm, and the thickness t3 of the opening end of the substrate 19 on the side of the lead parts 4b and 4c is set to 0.15 mm.

[0067] The thickness of the insulating film 21 can be adjusted as follows, that is, in the case of using a glaze or a slurry-like material, the glaze or the slurry-like material is coated on the entire surface of the inner peripheral surface of the base body 19, and in the firing process In this process, the base body 19 is rotated around its axis, and the axis of the base body 19 is maintained at a right angle with respect to the vertically downward direction, and then gradually becomes an ...

Deformed example 2

[0070] As shown in FIG. 3( c ), in the insulating film 22 of Modification 2, the thickness of the side farther from the sleeve lead 8 becomes smaller than that of the insulating film 21 closer to the sleeve 7 in the axial direction of the sleeve 7 compared to the insulating film 21 of Modification 1. The thickness of one side of the extended sleeve lead 8 is large.

[0071] For example, in the insulating film 22, on the side close to the sleeve lead 8, the thickness t4 of the opening end of the substrate 19 on the side of the turned-back end of the winding portion 4a is set to 0.05 mm, and the thickness t4 of the substrate 19 on the side of the lead wire portions 4b and 4c is set to 0.05 mm. The thickness t5 of the opening end of the coil is set to 0.10mm, and on the side away from the sleeve lead wire 8, the thickness t6 of the opening end of the substrate 19 on the side of the folded end of the winding part 4a is set to 0.10mm, and the lead wire parts 4b, 4c- The thickness t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com