Modulization-based method for designing reconfigurable machine tool

A design method and modular technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of not doing further research on the relationship between graphic representation and physical and mechanical modules, not considering design requirements, etc., to improve the level of structure. and flexibility of use, optimization of function and cost, effect of realizing function and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the content of the present invention and the embodiments described in the accompanying drawings.

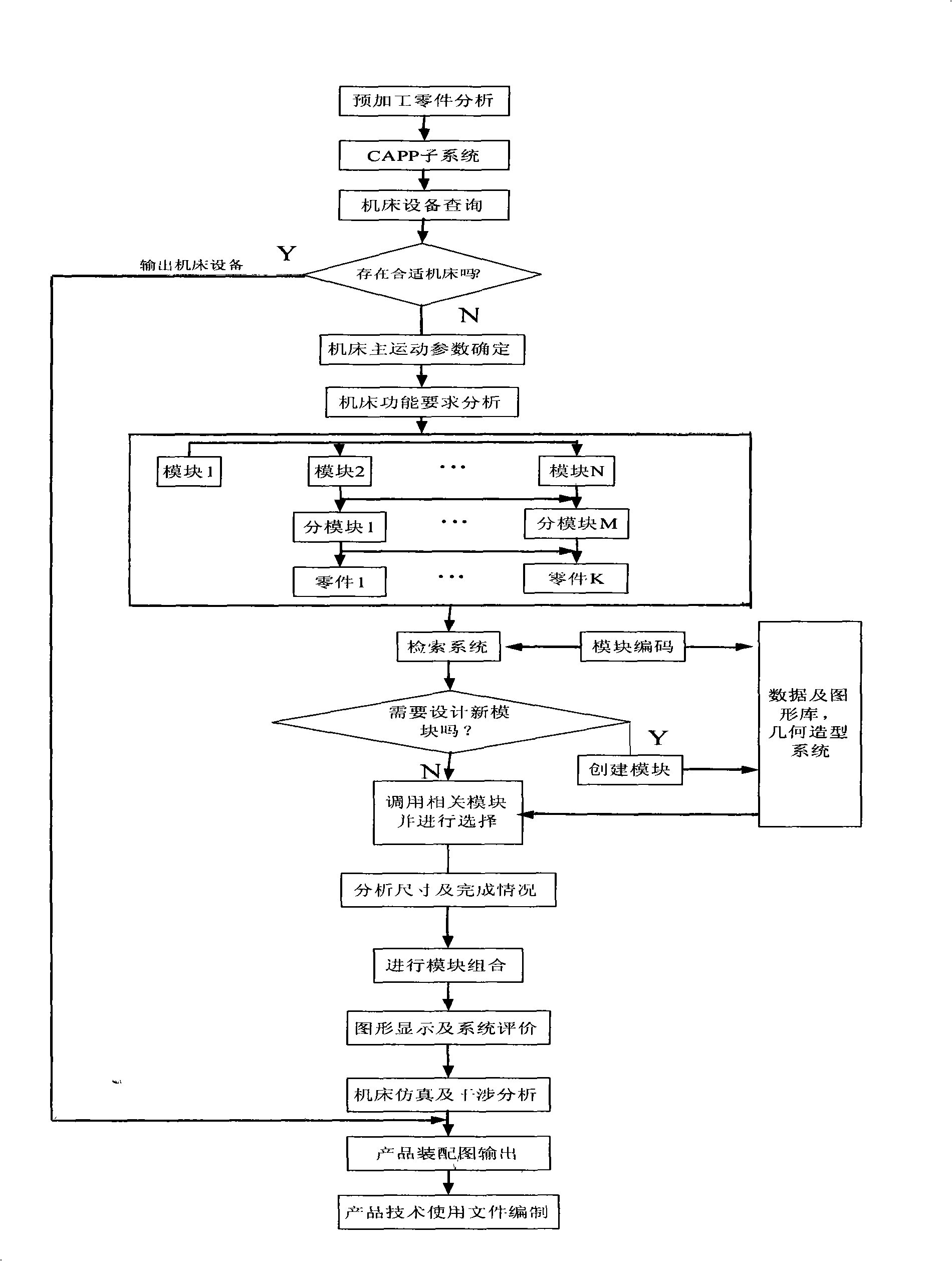

[0038] The present invention provides a modular reconfigurable machine tool design method, its structure is as follows figure 1 shown. The modularized reconfigurable machine tool design method is a machine tool design system that is more flexible and more suitable for needs by clustering the machine tool modules and optimizing and reorganizing different structures.

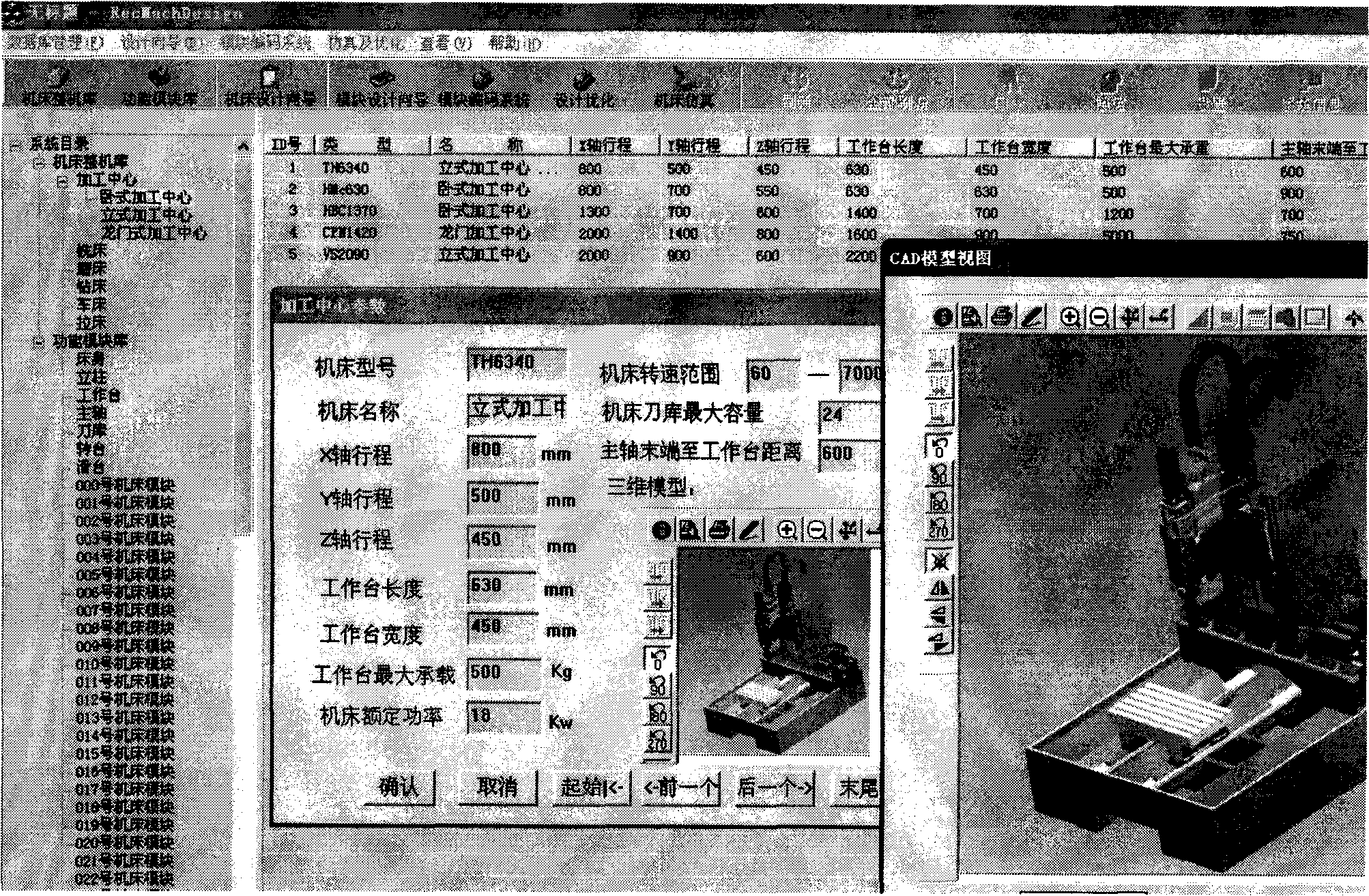

[0039] The system adopts an embedded design structure in the overall structure. In the system construction, the PRO / E software with strong portability is mainly used to establish the machine tool module model. The underlying database uses MySQL 5.1 to call and cluster each module. The modules are automatically assembled, and then ANSYS10.0 is called to perform dynamic and static analysis based on the modular reconfigurable machine tool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com