Connection channel positioning method in prefabrication of spliced tower crane foundation prefabricated by concrete

A positioning method and channel technology, applied in infrastructure engineering, manufacturing tools, ceramic molding machines, etc., can solve the problems of unstable interconnection of prefabricated parts, unstable foundation, and difficulty in connecting objects through connecting channels, etc., to achieve assembly and connection Convenience, formwork saving, solid foundation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

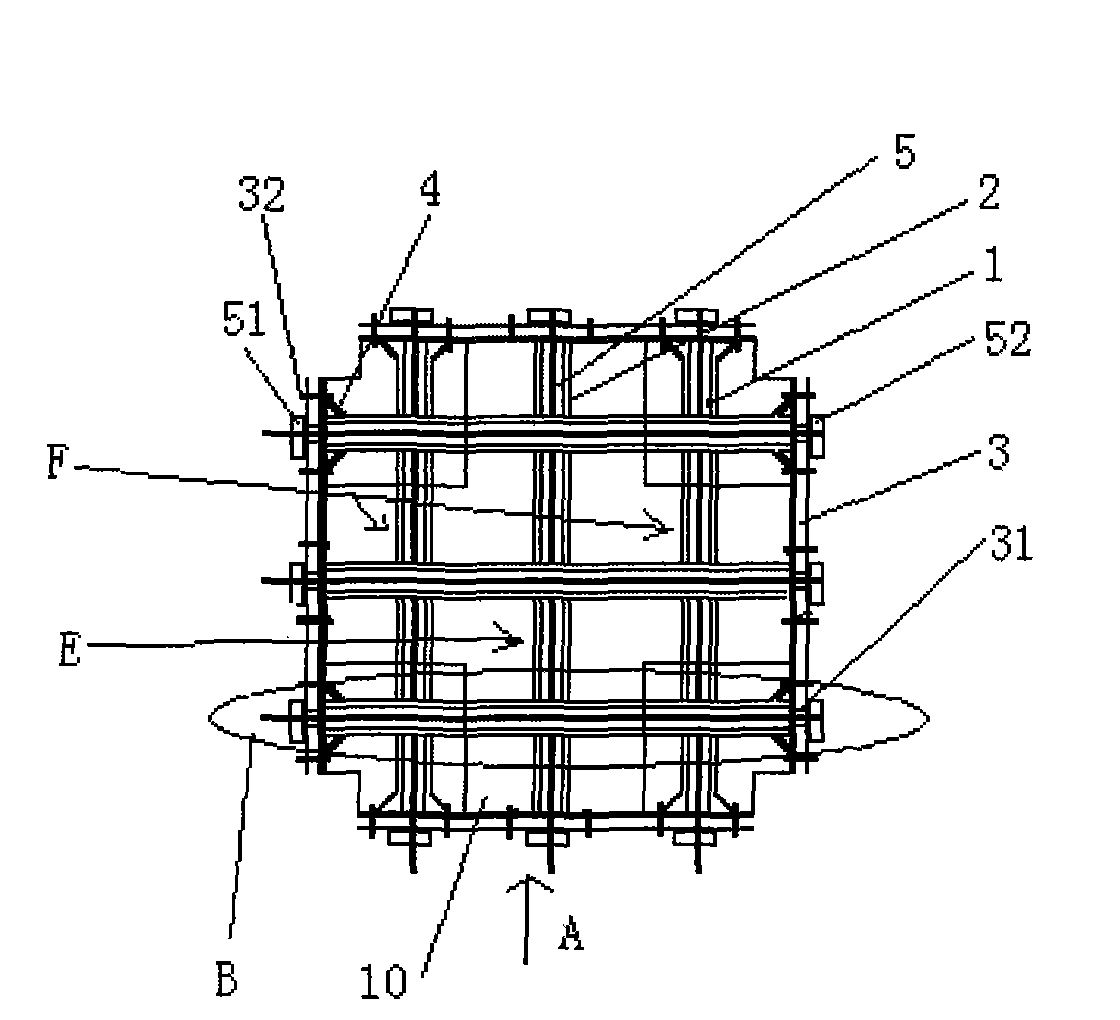

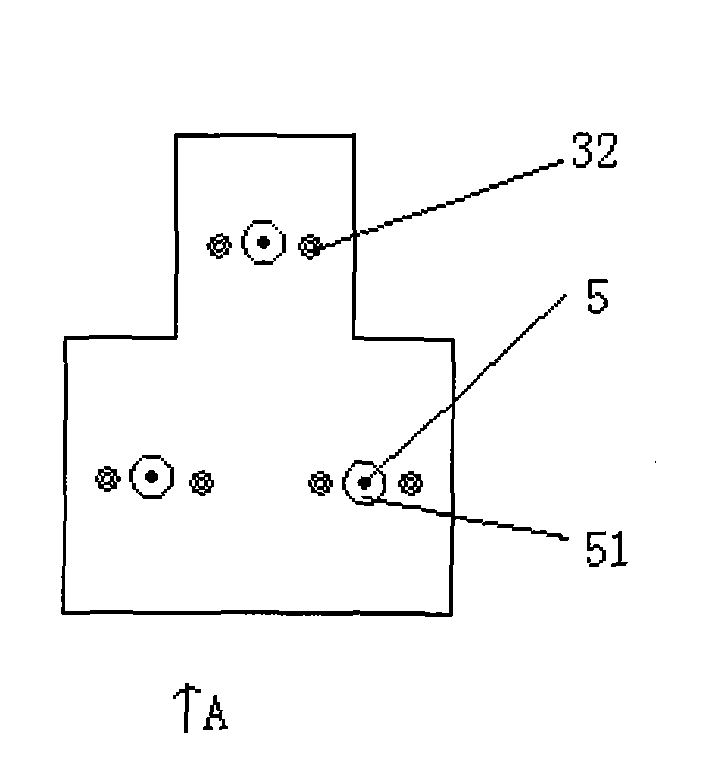

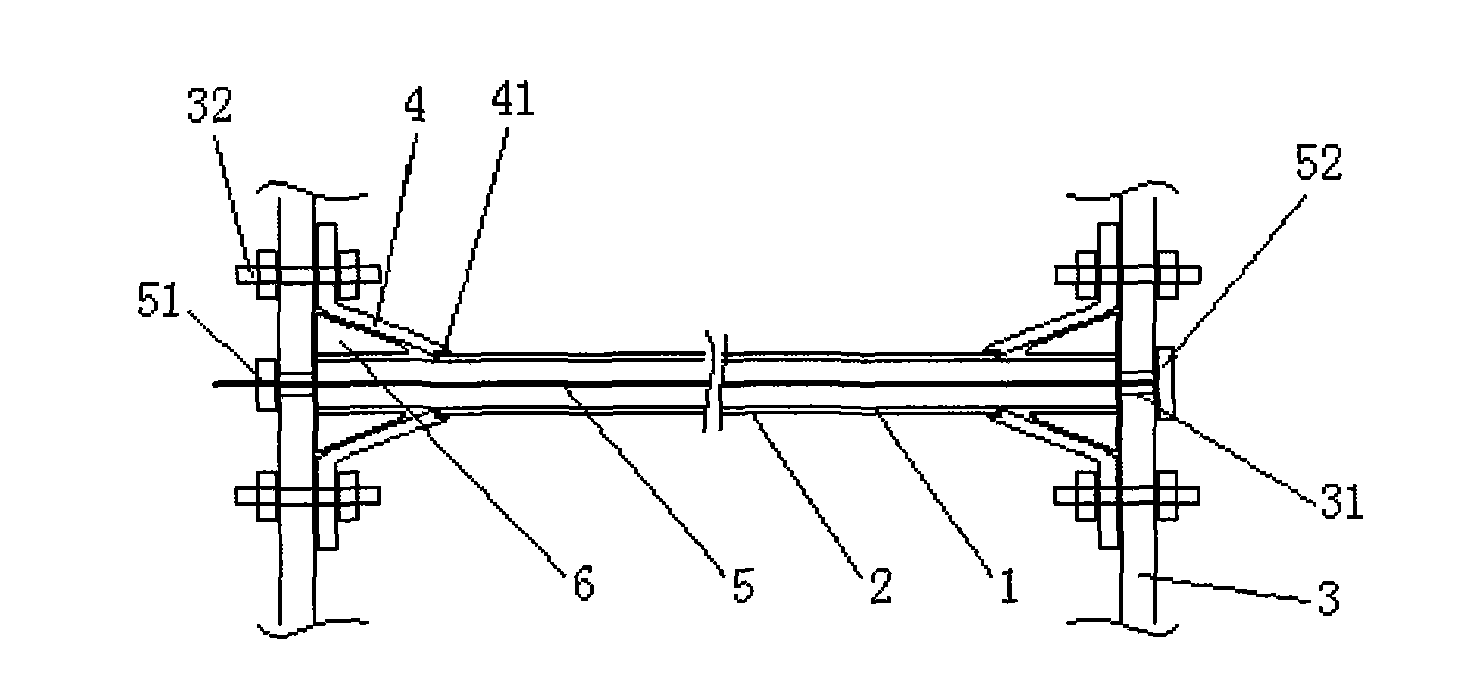

[0038] Such as figure 1 , 4 As shown in 6 and 6, there are three tunnels arranged in the same extension direction for the prefabricated parts of the prefabricated and assembled tower crane foundation, and the one in the middle is not provided with shear-resistant concave-convex parts, as shown in figure 2 As shown, the middle channel E is vertically arranged on the upper part of the convex shape of the end surface of the prefabricated part without setting the anti-shear concave-convex parts (in the actual prefabrication, the channel located on the upper part of the convex shape is generally provided with concave-convex parts, which are not set here. For the sake of clear expression in the figure), the other two channels F with shear concave-convex parts are vertically arranged at the lower part of the convex shape on the end surface of the prefabricated part (in the actual prefabrication, there are many channels without concave-convex parts at the lower part of the convex sha...

Embodiment 2

[0052] The prepared concrete prefabricated assembled tower crane foundation includes a central piece 10 and an end piece 9 .

[0053] First make the center piece as in Example 1, and then make the end pieces. Coat the connecting end of the center piece with isolation paint for later use; make the reinforcement cage of the end piece according to the conventional method, set the convex piece of the shear-resistant concave-convex piece at one end of the reinforcement cage of the end piece, and use the end with the convex piece as the connection with the center piece end, the convex head of the convex piece is inserted into the notch of the concave piece set by the center piece, the flash surfaces of the concave piece and the convex piece are fitted together, one end of the pre-embedded pipe is inserted into the gap around the center hole of the convex piece, and the other end extends to the vertical surface of the formwork, Insert the metal liner into the embedded pipe until it p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com