Elastic bar mounting method and elastic bar mounter

An installation method and installation technology, which are applied to fixed rails, roads, tracks, etc., can solve the problems of difficulty in quality assurance, low construction efficiency, and large labor consumption, and achieve stable construction quality, ensure installation quality, and speed up. The effect of efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

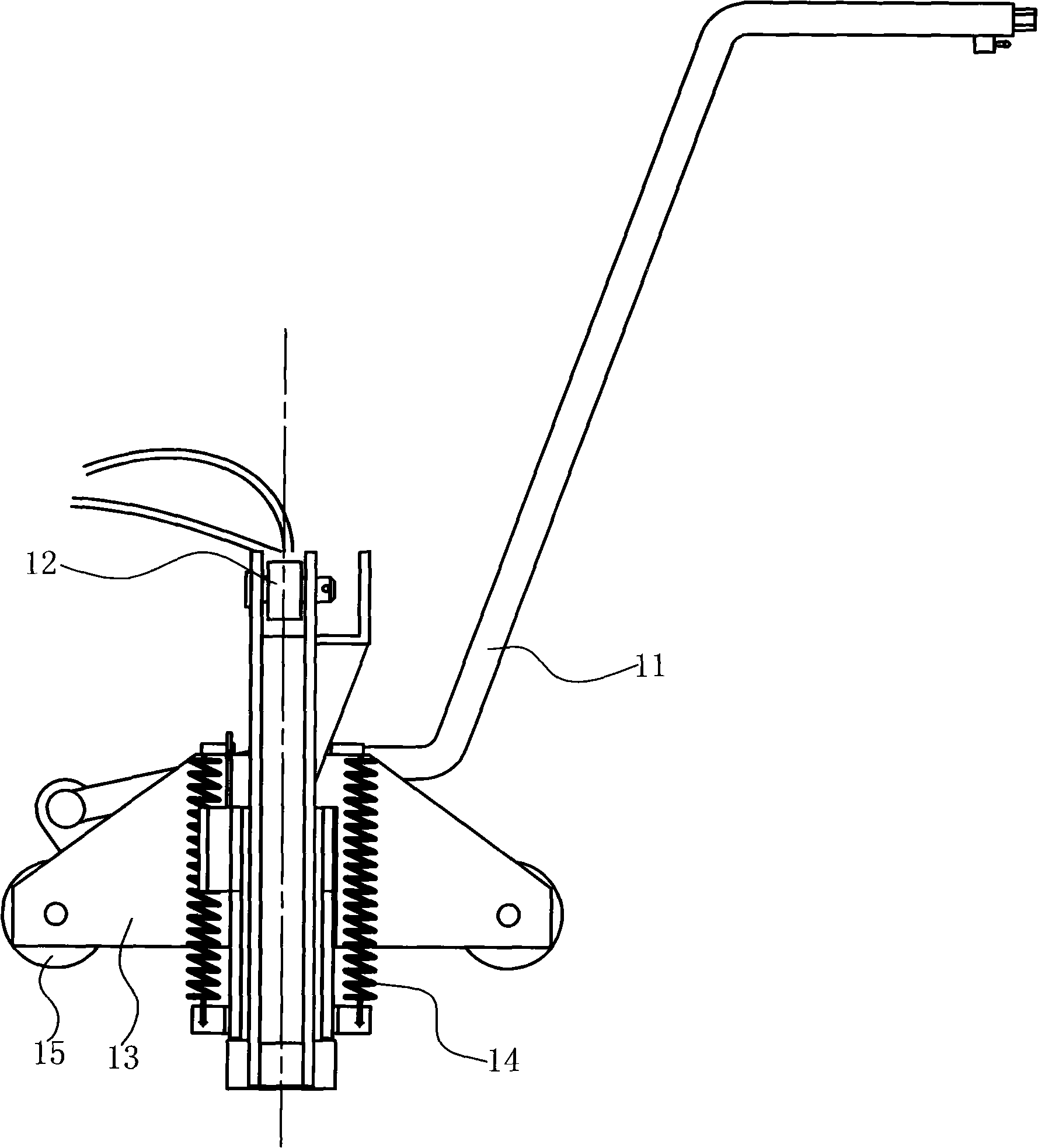

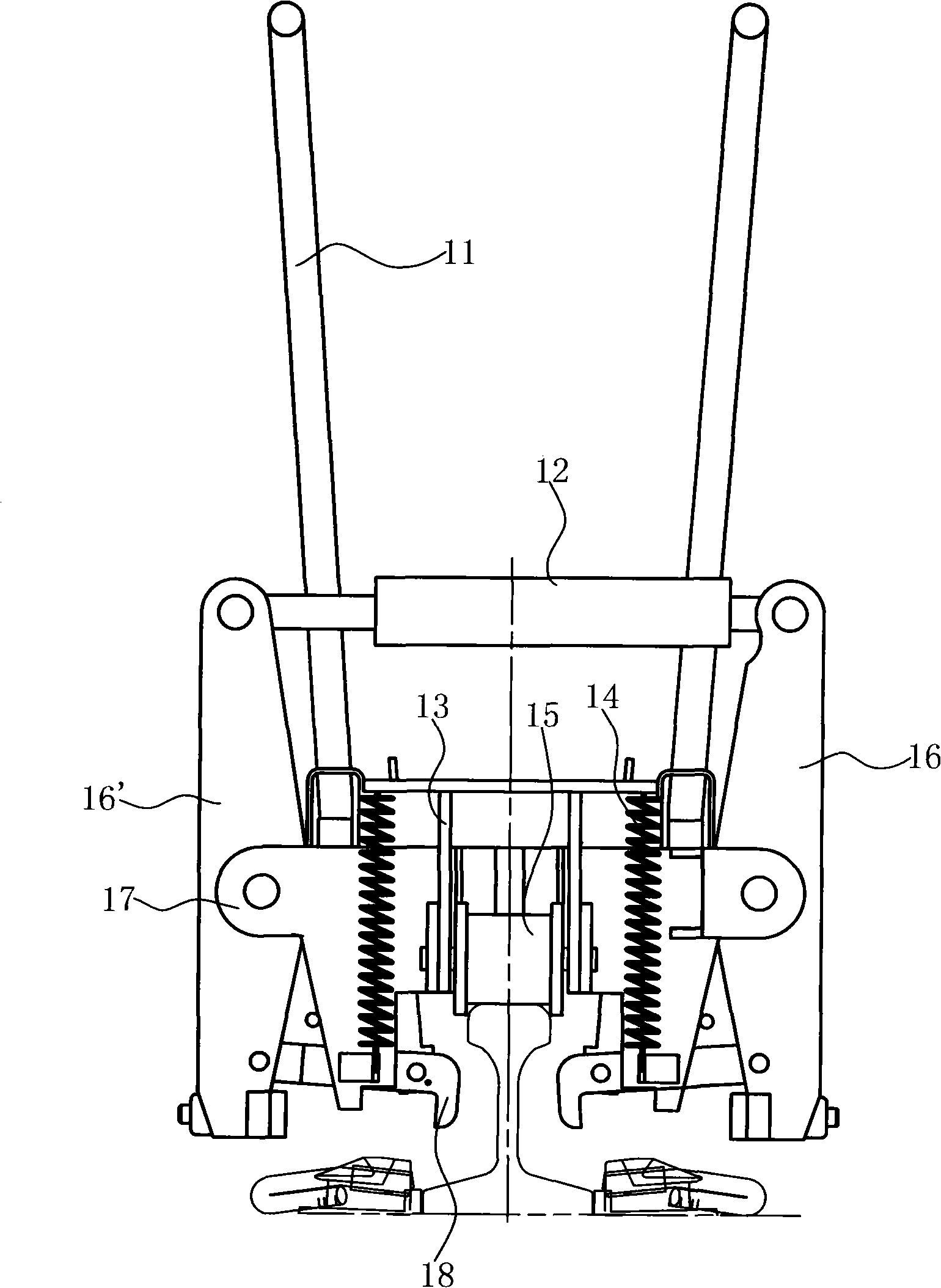

[0026] The elastic bar installation method adopts an elastic bar installer that is elastically connected to a mounting bracket that can walk on the rail, and the mounting bracket is suspended on the running bracket through a set of springs. The installation bracket and the two installation arms go down to the installation position of the elastic strip. Two installation arms are hingedly arranged on the installation bracket, and the upper part of the installation arm is driven and connected by a driving mechanism, so that the elastic strip installed at the bottom of the two installation arms is installed. The device stretches and shrinks relative to the side of the rail to complete the installation of the spring bars. The driving mechanism between the upper parts of the two mounting arms is the acting oil cylinder, which is set horizontally. When it expands and contracts, the upper parts of the two mounting arms move around the hinged position of the mounting arms, so that the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com