Method for applying continuously adjustable uniaxial stress to semiconductor samples at low temperature

A semiconductor and sample technology, which is applied in the field of semiconductor wafer measurement, can solve the problems of unrecoverable samples and small degrees of freedom, and achieve the effects of good thermal conductivity, small size, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

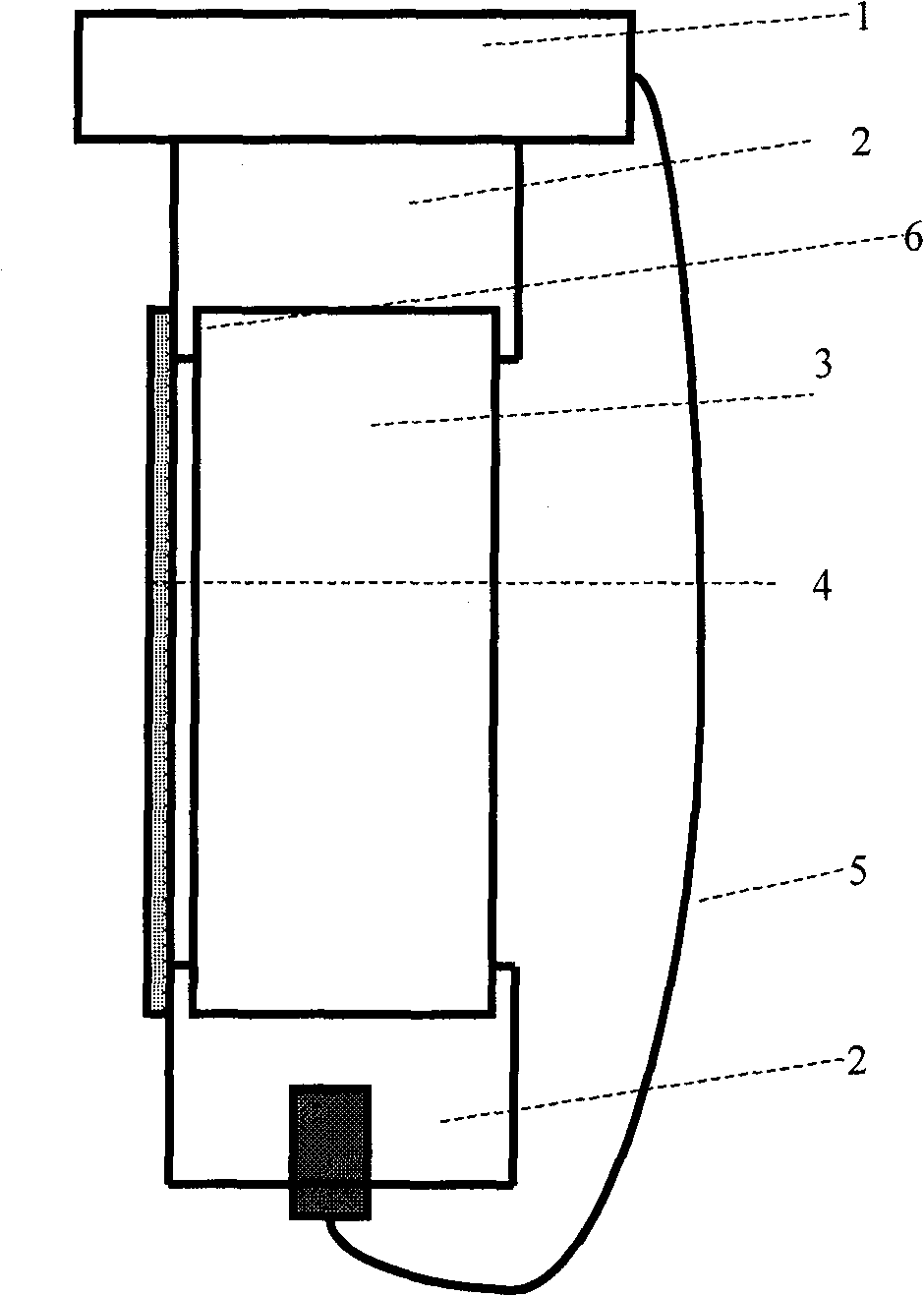

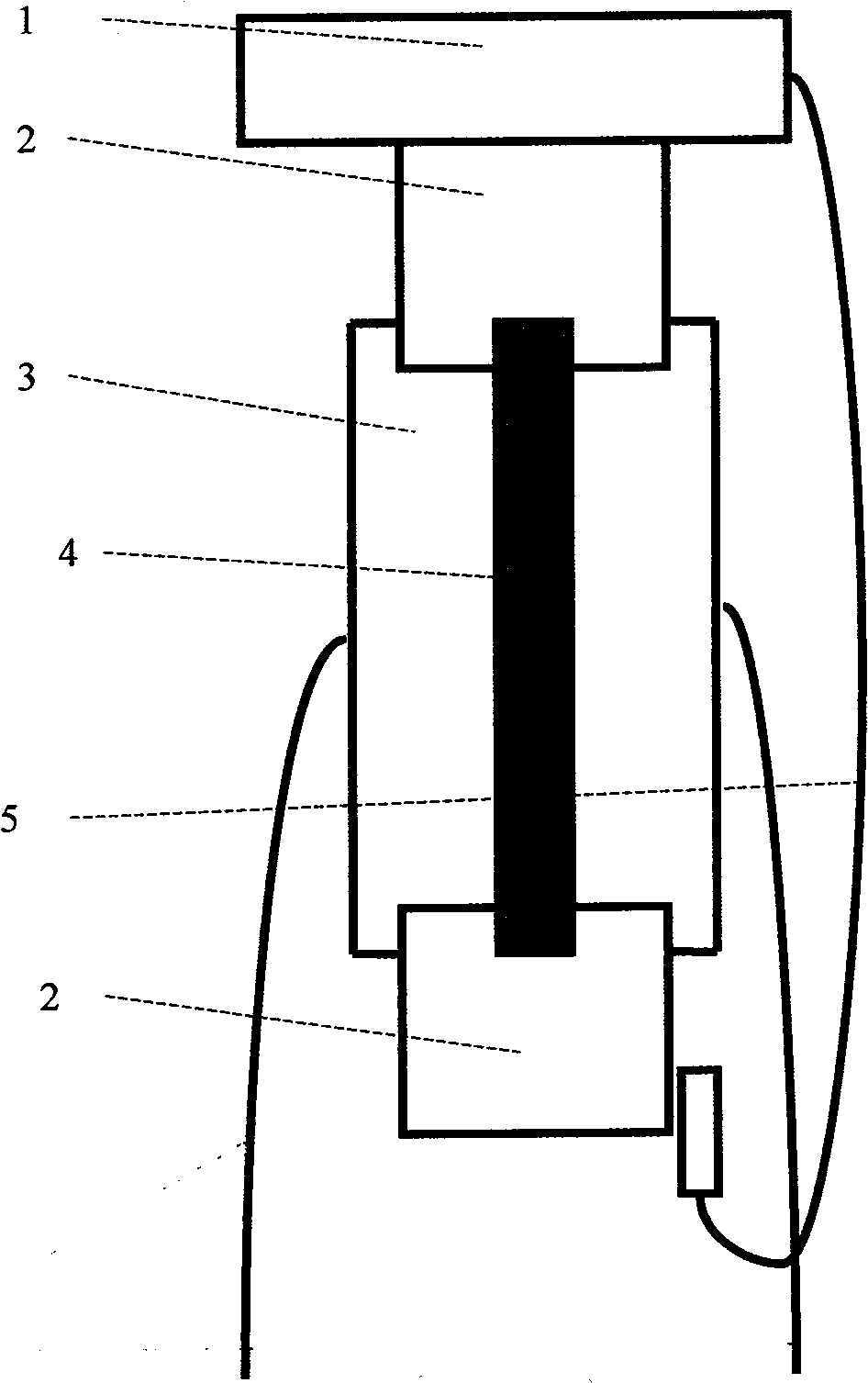

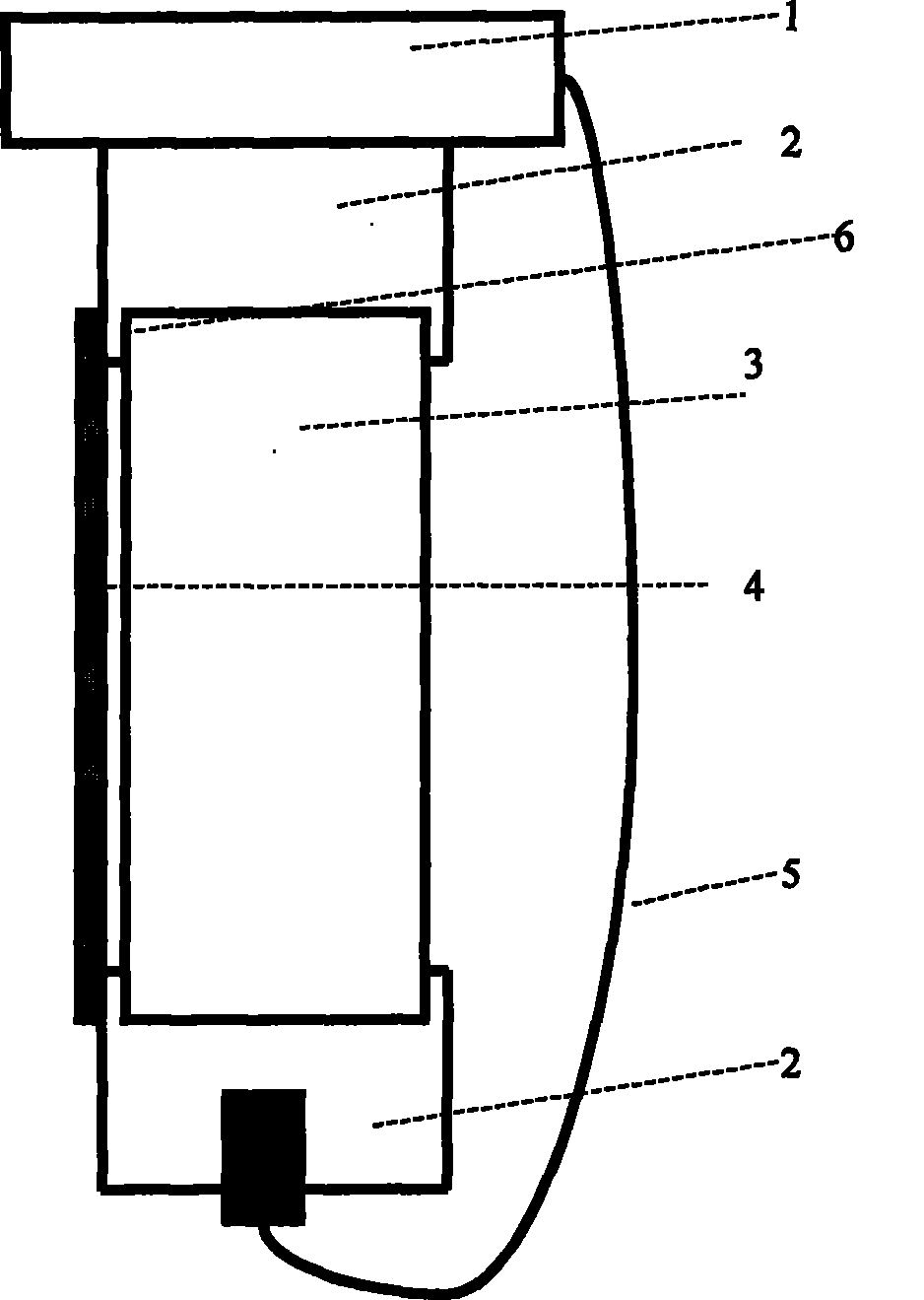

[0036] 1) Use the U-shaped red copper cap 2 with an overall size of 11×5×6.5mm, the depth of the groove is 2mm, the thickness of the outer walls on both sides of the groove is 0.5mm, and the size of the piezoelectric ceramic 3 is 5×5×9mm.

[0037] 2) Sample 4 is a GaAs / AlGaAs superlattice with a length of 7 mm, a thickness of 0.5 mm, 30 periods, and a GaAs / AlGaAs superlattice grown along the [001] direction. The substrate is GaAs, and the sample is cut along the [110] direction. Use the commercially available "Anteco" superglue to bond the two ends to the two copper caps 2, and then use a hair dryer to blow hot air on the bonding place for 15 minutes.

[0038] 3) Fix a red copper cap 2 on the heat transfer metal probe 1 of the small Dewar flask with screws, and use low-temperature vacuum grease at the joint to enhance contact and heat conduction.

[0039] 4) The other copper cap 2 is connected to the heat transfer probe 1 of the cryogenic device through the copper heat conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com