Sealing films for solar cell

A technology of solar cells and sealing films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as rust, and achieve the effects of improving durability, preventing corrosion, and high power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

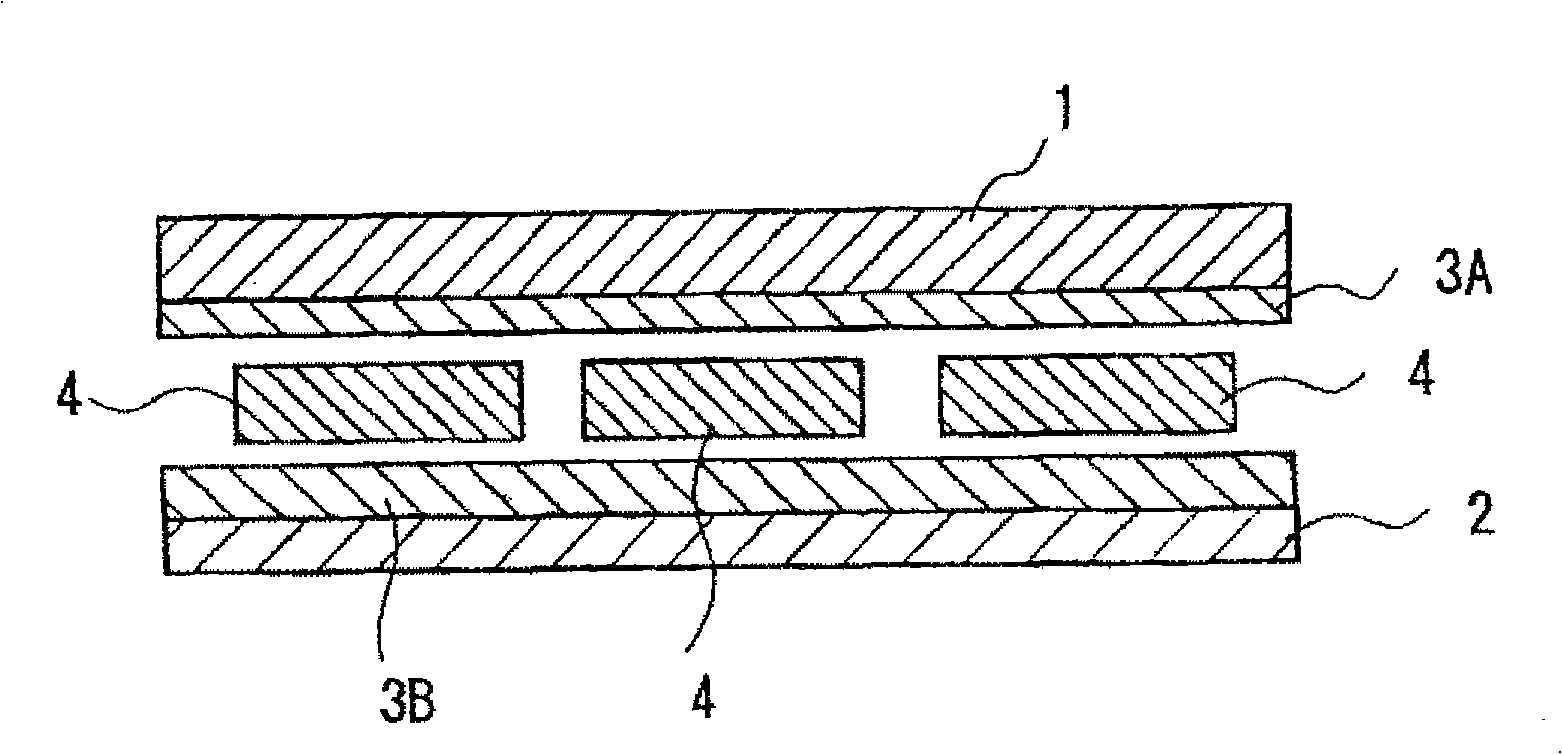

Image

Examples

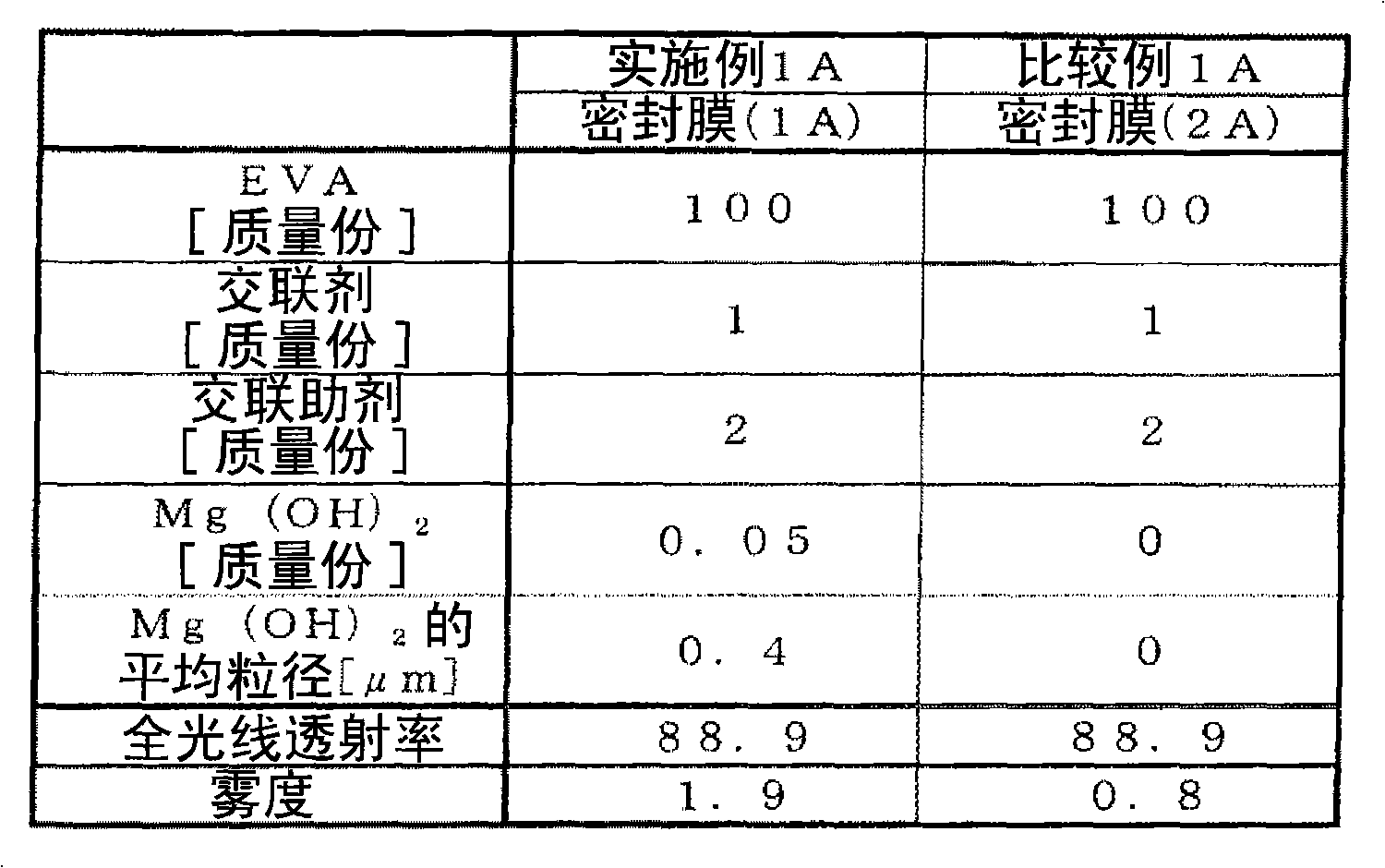

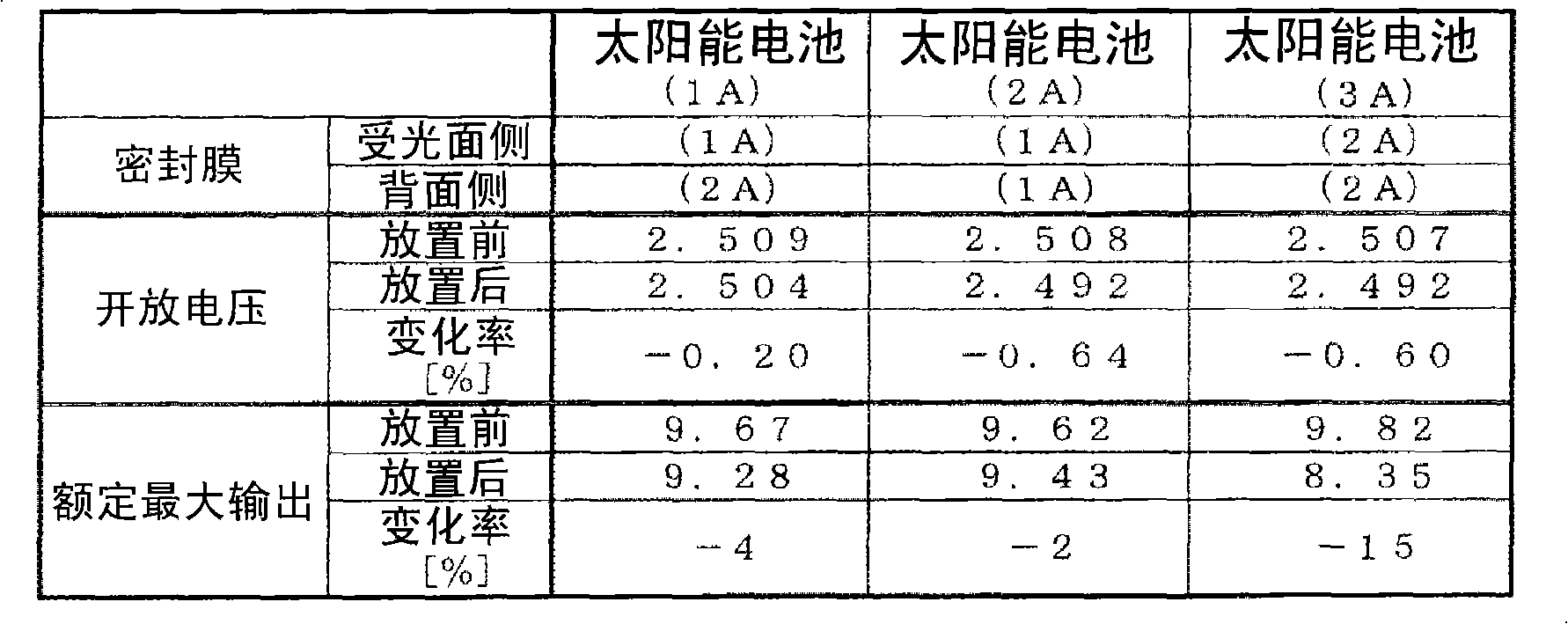

Embodiment 1A

[0094] 100 parts by mass of EVA (content of vinyl acetate relative to 100 parts by mass of EVA: 26 parts by mass),

[0095] 1 part by mass of crosslinking agent (2,5-dimethyl-2,5-bis(t-butylperoxy)hexane),

[0096] 2 parts by mass of crosslinking aid (triallyl isocyanurate),

[0097] Acid absorbent (Mg(OH) 2 , average particle size 0.4μm) 0.05 parts by mass,

[0098] Using the above formula, these materials were put into a roller mill, kneaded at 80°C to prepare a resin composition, and the obtained resin composition was rolled and formed at 100°C, and after slow cooling, a sealing film with a thickness of 0.6mm was obtained ( 1A).

Embodiment 1B

[0118] 100 parts by mass of EVA (content of vinyl acetate relative to 100 parts by mass of EVA: 26 parts by mass)

[0119] 1 part by mass of crosslinking agent (2,5-dimethyl-2,5-bis(t-butylperoxy)hexane)

[0120] 2 parts by mass of crosslinking aid (triallyl isocyanurate)

[0121] Acid absorbent (Mg(OH) 2 , average particle size 3μm) 0.5 parts by mass

[0122] Using the above formula, these materials were put into a roller mill, kneaded at 80°C to prepare a resin composition, and the obtained resin composition was rolled and formed at 100°C, and after slow cooling, a sealing film with a thickness of 0.6mm was obtained ( 1B).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com