Plasma processing apparatus

A processing device, plasma technology, applied in the directions of plasma, gaseous chemical plating, coating, etc., can solve the problem of satisfactory plasma uniformity, achieve high uniformity, reduce the influence of end effect, and ensure axial symmetry sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042]

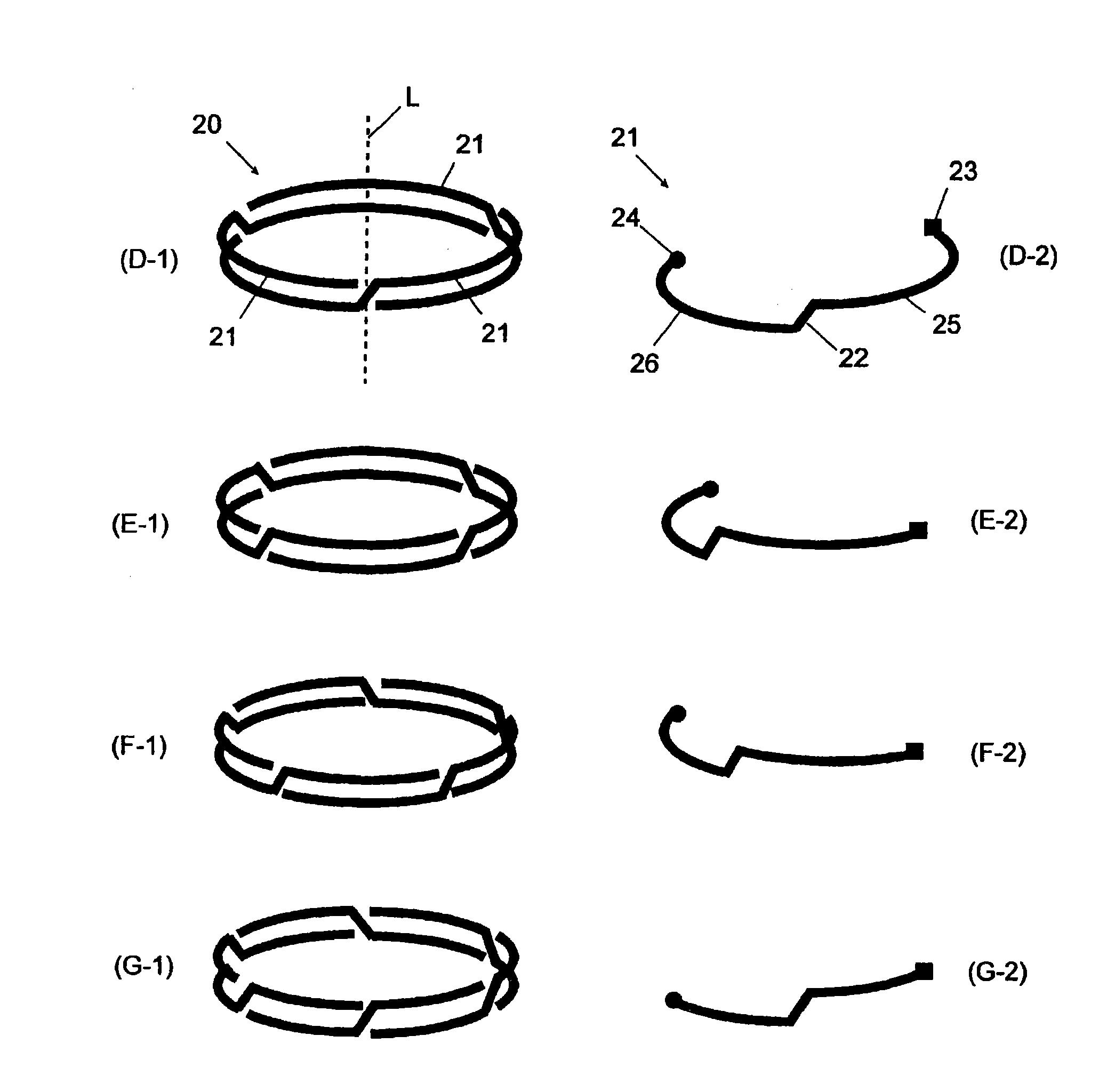

Figure 6 A schematic configuration diagram of an ICP etching apparatus 10 configured by arranging the induction coil 30 according to the third embodiment on the upper portion of the quartz plate 15 is shown. exist Figure 6 In , illustration of a gas introduction unit, a vacuum pump, a cooling device, etc. is omitted.

Figure 6 The induction coil 30 is shown, with and Figure 4 The induction coils shown have the same structure and are composed of a first induction coil 31 and a second induction coil 32, the former consisting of five coil elements and the latter consisting of three coil elements. The first and second induction coils 31 and 32 are arranged on the quartz plate 15 by using the alignment pad 34 so that the respective upper surfaces are on the same plane.

[0043]

The first and second induction coils 31 and 32 are arranged with the central axis L of the silicon wafer as a common axis among the normal lines to the surface of the silicon wafer, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com