Preparation method for producing wood board or flitch beam

A technology of planks and squares, applied in the field of preparation of wooden planks or squares, to achieve the effects of low water expansion rate, small natural deformation, high nailing force and high use strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiments:

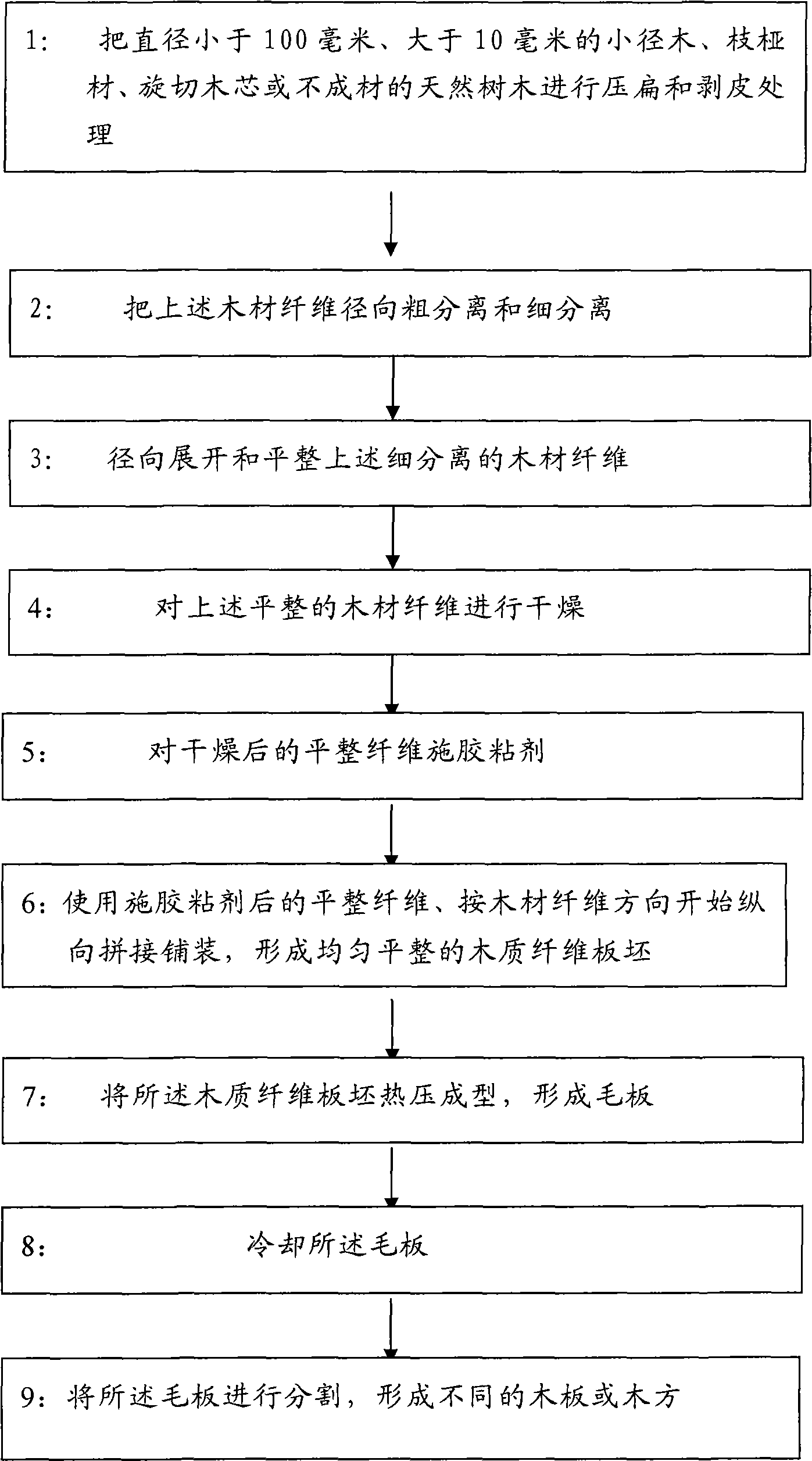

[0026] As shown in the drawings, the method of the present invention includes the following steps:

[0027] a. Send small-diameter wood, branch wood, peel-cut wood core or incomplete natural trees (such as medlar, etc.) with a diameter of less than 100 mm and greater than 10 mm into a flat cold press or rolling machine with peeling Flattening and peeling treatment;

[0028] b. Then the squashed and peeled small-diameter wood, branch wood, peel-cut wood core or incomplete natural trees are fed into the wood fiber separator in the length direction to carry out the radial coarse and fine separation of wood fibers;

[0029] c. Expand and smooth the above-mentioned finely separated wood fibers radially;

[0030] d. Dry the above-mentioned smooth wood fiber;

[0031] e. Apply adhesive to the dried smooth fiber;

[0032] f. Use the flat fiber after sizing the adhesive, and start the vertical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com