Method for preparing high-purity electro-melting corundum aluminum oxide epoxy casting filler

A technology of fused corundum and epoxy casting, which is applied to insulating packaging materials in the electronic field and electrical fields, and can solve the problems of short service time, high initial viscosity of epoxy casting materials, and difficulty in using insulating casting materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

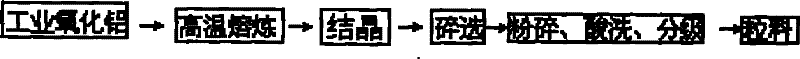

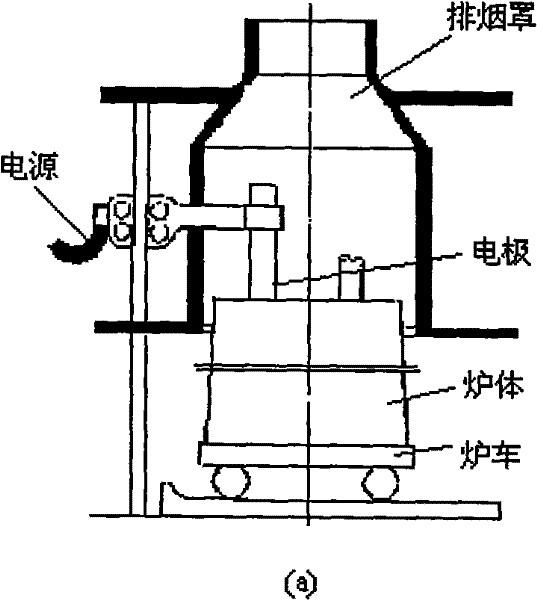

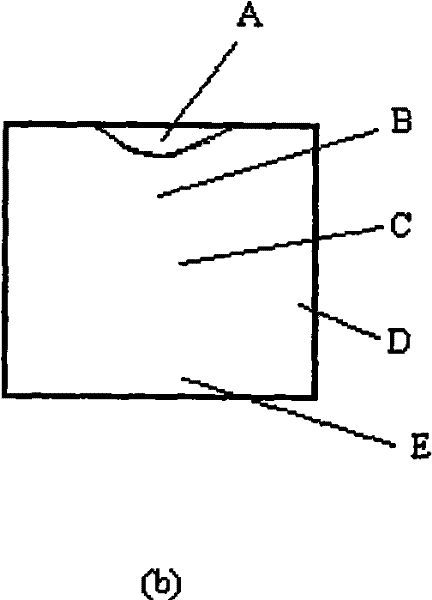

[0022] see figure 1 , figure 1 It is the process flow diagram of the existing electrofusion method;

[0023] Electrofusion Al 2 o 3 The filler particles are all single crystals, the surface of the filler particles is smooth and flat, there are no air bubbles in the particles, the specific surface area of the filler particles is small, and the amount of epoxy resin required to infiltrate the surface of the particles is also small, and a variety of particle sizes can be used to increase the amount of filler added. However, there are many varieties of fused corundum, which mainly come from the abrasive industry, among which fused white corundum has the highest purity of alumina. Medium Al in fused white corundum 2 o 3 The content is more than 99%, but the main Na in the abrasive industry fused corundum 2 The O impurity amount is too high, reaching more than 0.5%, which is much higher than that of epoxy cast alumina filler Na 2 The O content standard results in a small am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com