Method for depredating acetylene hydrocarbon in cracked carbon-5 distillate by acetylene hydrocarbon post-depredation process

A post-dealkyne and carbon cracking technology, applied in chemical instruments and methods, distillation purification/separation, hydrocarbon purification/separation, etc., can solve problems such as isoprene loss, reduce operating costs, increase productivity, The effect of improving load conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

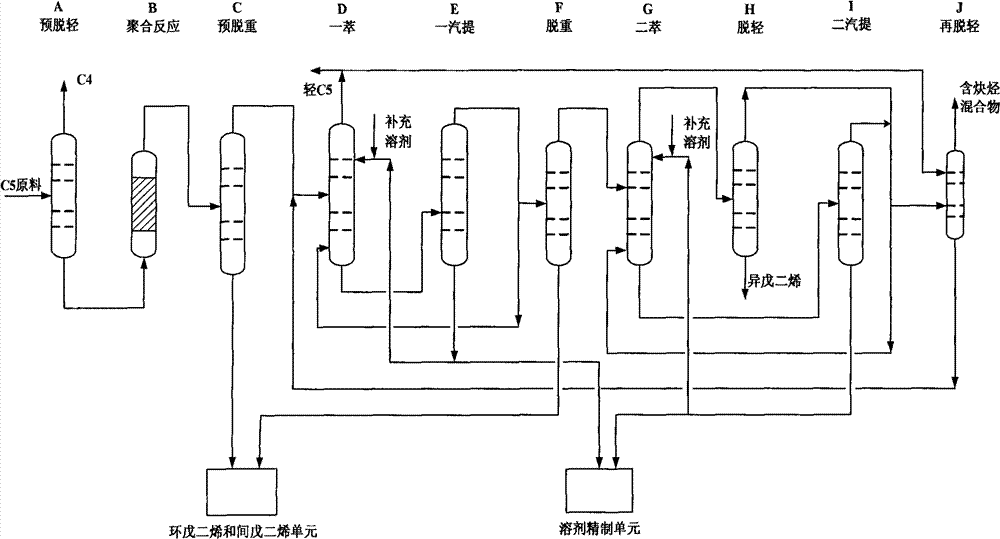

[0054] For the flow of the embodiment, see figure 1 . As shown in the figure, devices A to I are basically similar to the prior art, but the light removal tower J and the associated logistics pipeline are the innovation points of the present invention. In this embodiment, the theoretical plate number of the re-light stripping tower is 40, the positions of the upper and lower feed ports are respectively 16 and 26, and the reflux ratio is 8. The stream mass concentration data of each tower is shown in Table 1.

[0055] Table 1 embodiment stream concentration data (w%)

[0056] Feed Dtop Gtop Htop Hlow Itop Jtop Jbottom

[0057] Carbon 4 7.54 0.04 0.06

[0058] 3-Methylbutene-1 0.94 5.70 8.42 0.10

[0059] n-Pentane 6.65 24.63 17.52 13.87

[0060] Pentene-1 4.72 14.77 15.56 4.80

[0061] 2-Methylbutene-1 6.98 17.42 16.87 6.76

[0062] Transpentene-2 3.20 11.30 0.01 0.07 1.98 10.57

[0063] Cis-pentene-2 2.07 7.08 0.01 0.07 0.61 7.09

[0064] Pentadie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com