Gas jet device of electric control jet lean-burn natural gas engine and jet control method

A technology of injection device and electronically controlled injection, applied in engine control, combustion engine, internal combustion piston engine, etc., can solve the problems of gas jet motion energy loss, improve the combustion quality of lean-burn engine, expand stable operation limit and reduce problems, and achieve expansion Lean limit, extended stable operation lean limit, improved combustion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

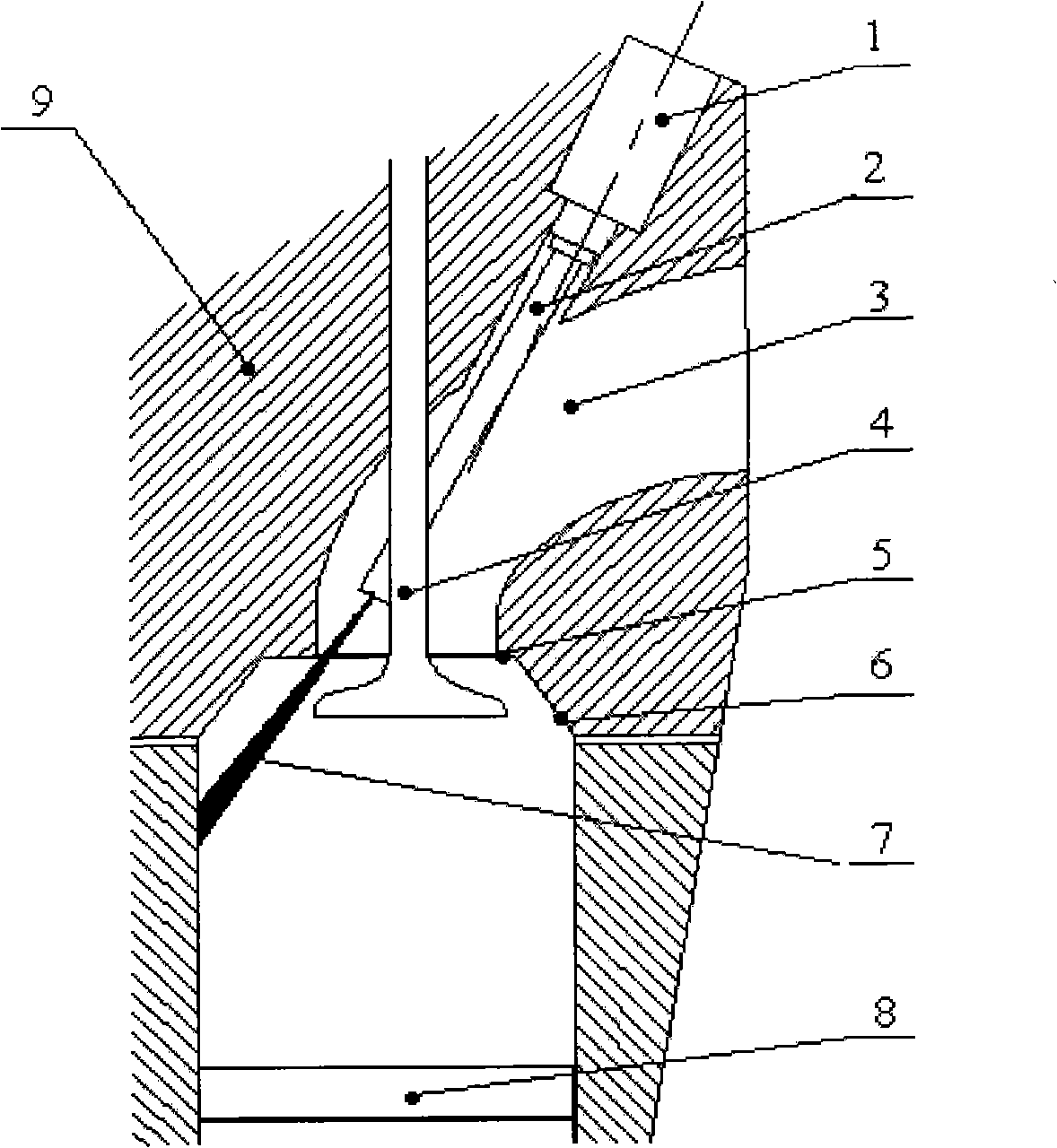

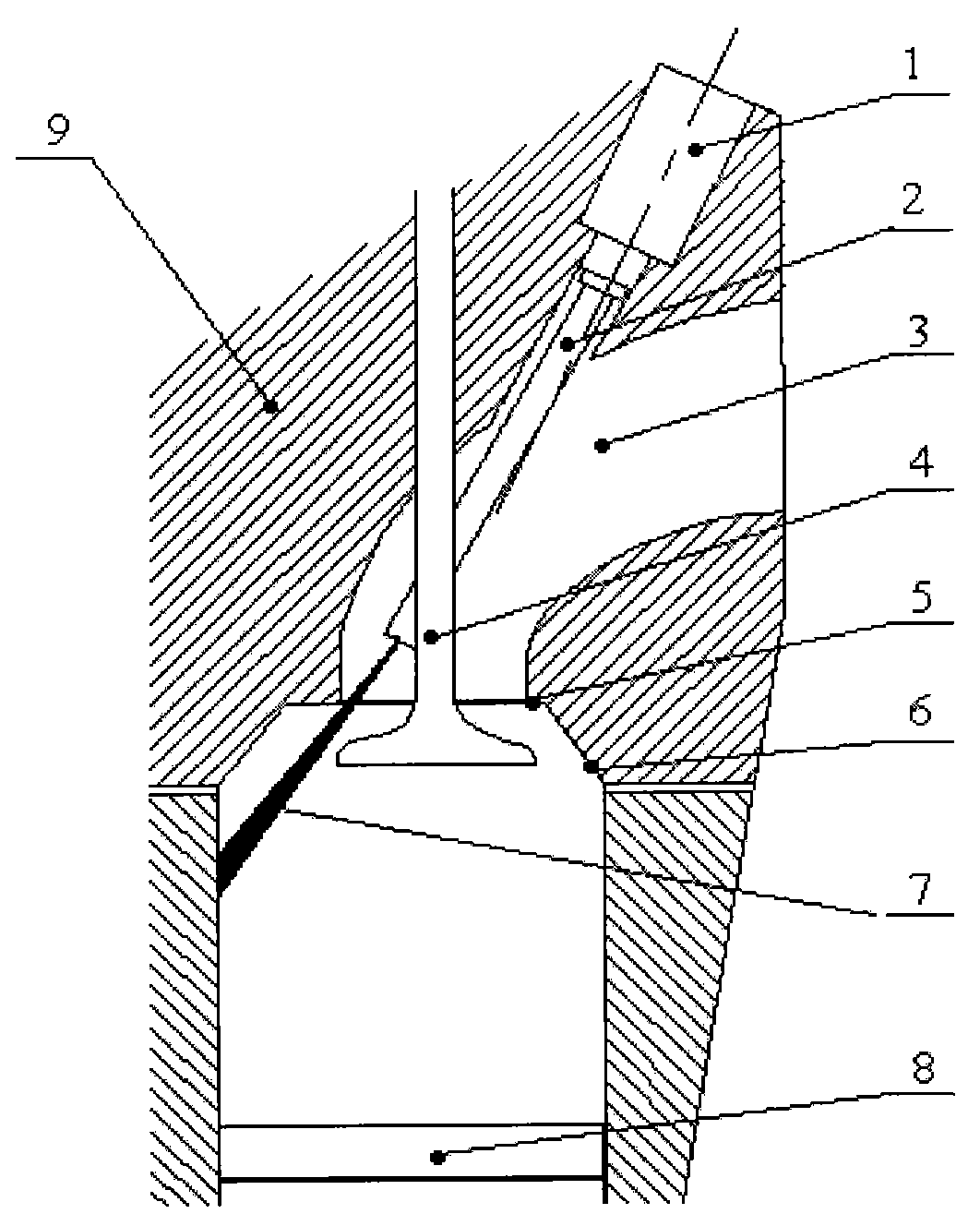

[0017] Combine figure 1 , The composition of the gas injection device of the electronically controlled injection lean burn natural gas engine of the present invention is: the electronically controlled multi-point injection fuel supply system uses a large flow natural gas nozzle 1. The nozzle 1 is installed on the cylinder head 9 or the intake manifold, below the nozzle Install a gas draft tube 2, the inner diameter of the draft tube 2 is the same as the exit diameter of the natural gas nozzle 1, and the center line of the draft tube 2 and the center line of the intake valve 4 are two non-parallel or intersecting spatial straight lines to ensure the guide The flow tube 2 does not touch the valve stem or affect the movement of the intake valve 4. Under the action of the guide tube 2, the jet pulse 7 does not collide with the surface of the intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com