Direct spraying natural gas two-air valve engine underpressure layered combustion chamber structure in cylinder

A natural gas and combustion chamber technology, applied in the direction of internal combustion piston engine, engine ignition, engine components, etc., can solve the problem of soot emission, and achieve the effect of low cost, improved power and economy, and low emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

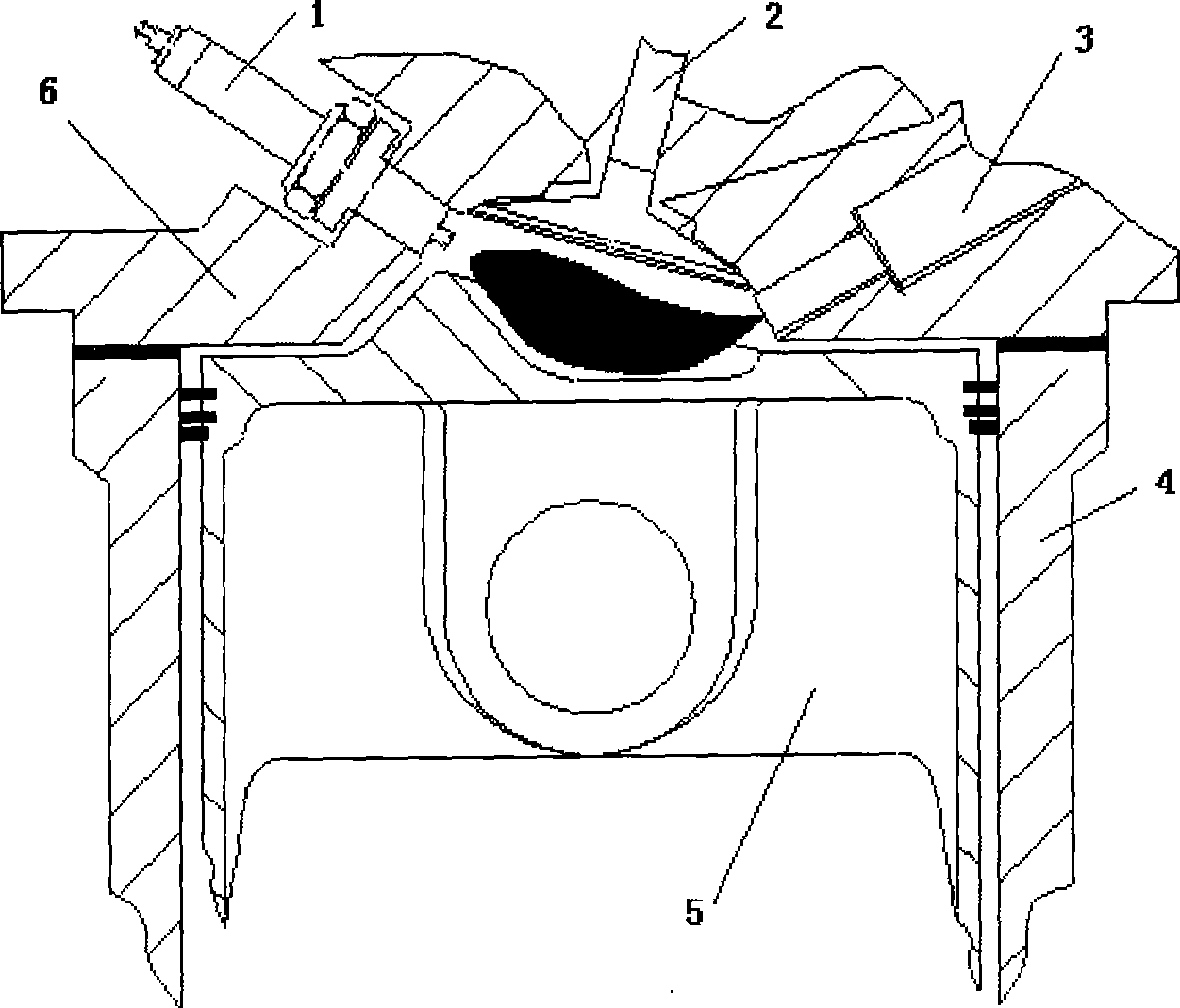

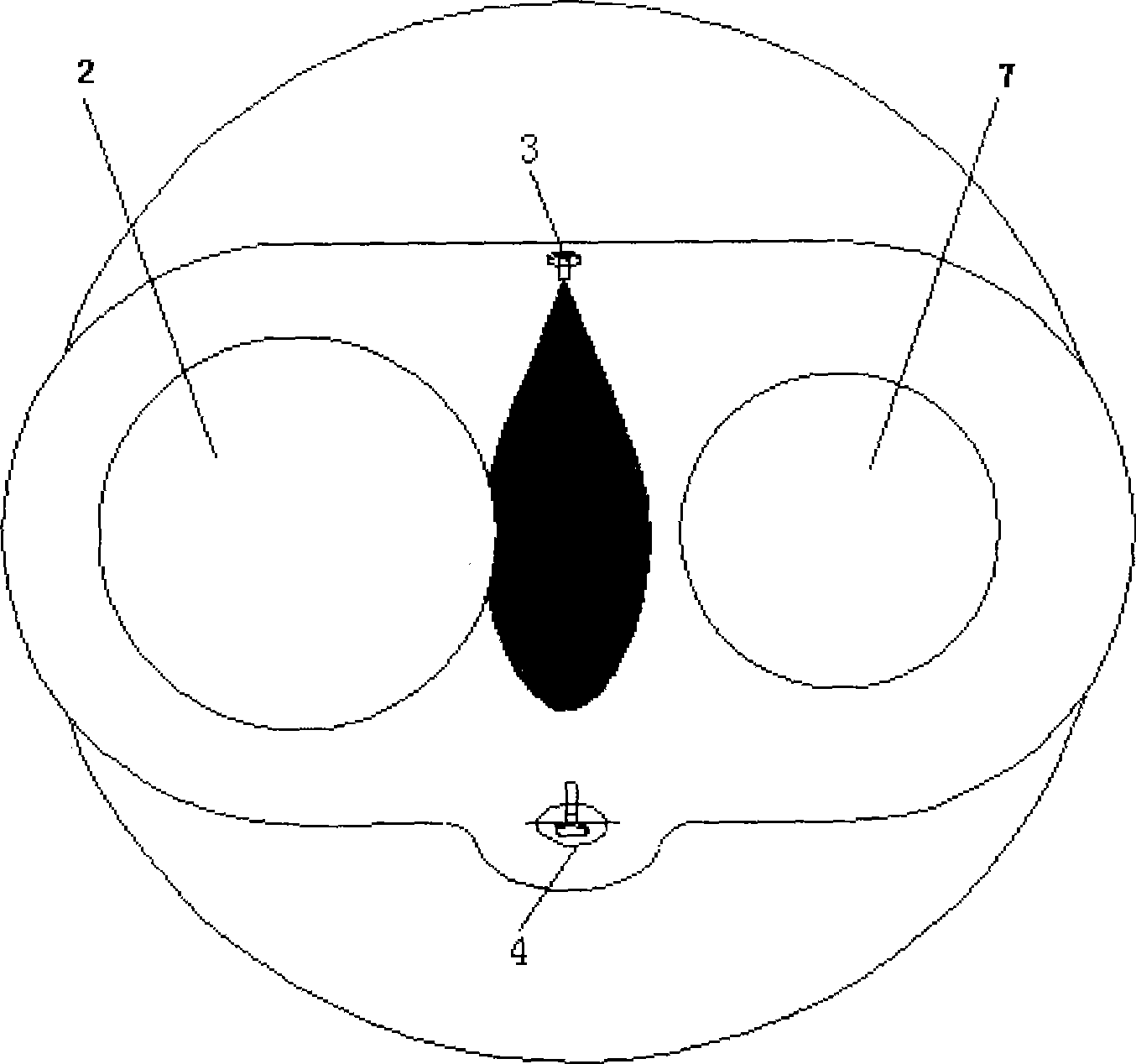

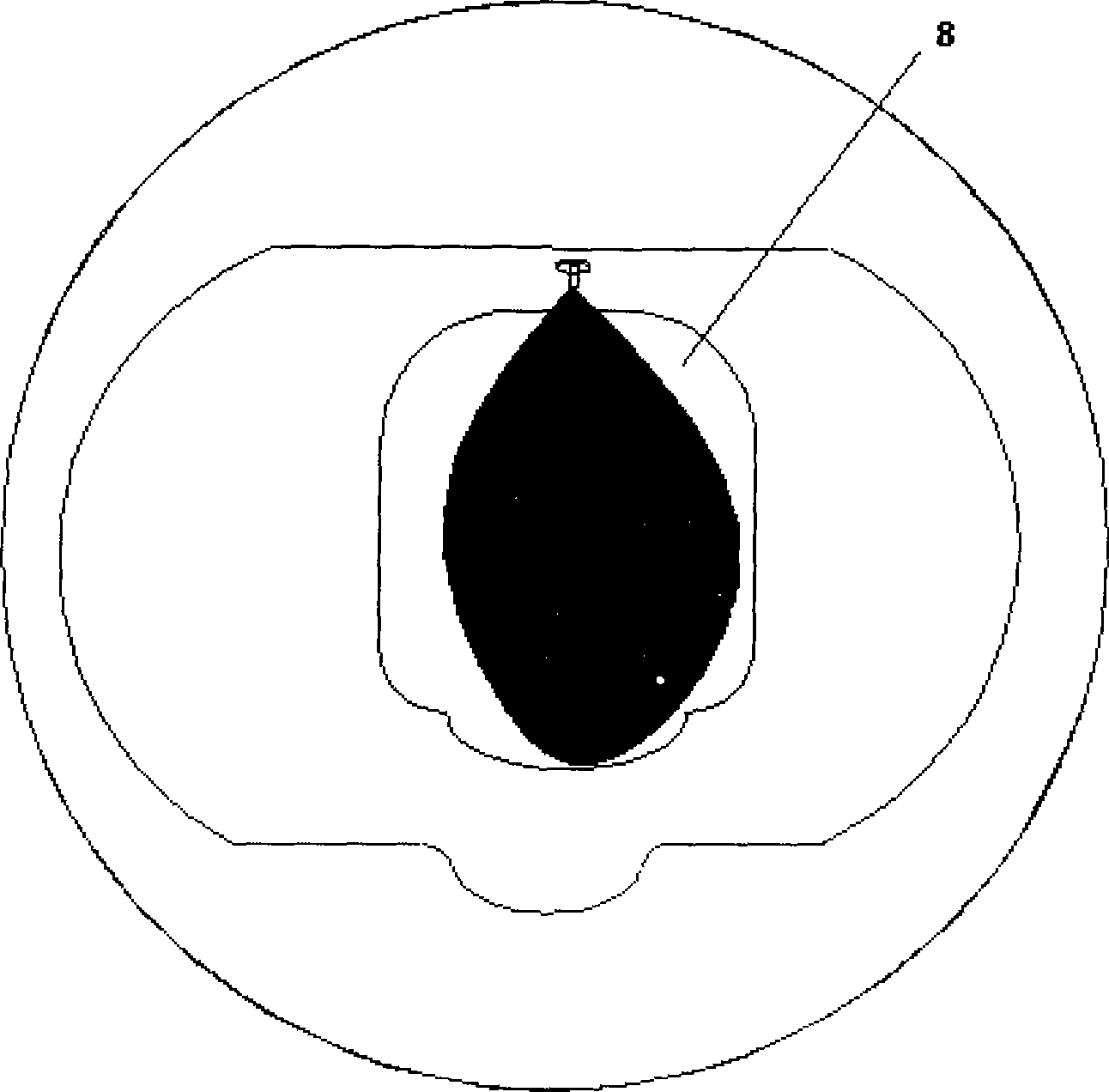

[0016] Such as figure 1 , a lean stratified combustion chamber structure of an in-cylinder direct injection natural gas two-valve engine, including a piston 5, a cylinder head 6, a cylinder block 4, an intake valve 2 and an exhaust valve 7, and a guide groove is arranged on the top surface of the piston 5 Pit 8, the natural gas nozzle part 3 is installed on the cylinder head 6, near the larger part of the curvature radius of the diversion pit 8; the spark plug 1 is also installed on the cylinder head 6, the position is opposite to the natural gas nozzle 3, and the spark plug 1 is close to the diversion pit The portion of the pit 8 with a smaller curvature radius. The volume of the combustion chamber includes the volume of the diversion pit 8 on the top surface of the piston and the clearance volume, and the volume of the diversion pit 8 on the top surface of the piston accounts for 60% to 70% of the total volume of the entire combustion chamber. The depth of the part with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com