A Gas/Dual Fuel Engine Gas Ladder Injection Device

A dual-fuel engine and injection device technology, which is applied to fuel injection devices, combustion engines, machines/engines, etc., can solve problems such as combustion stability and NOx emission performance are not ideal, to achieve the expansion of lean burn limit, improve combustion quality, The effect of speeding up the mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

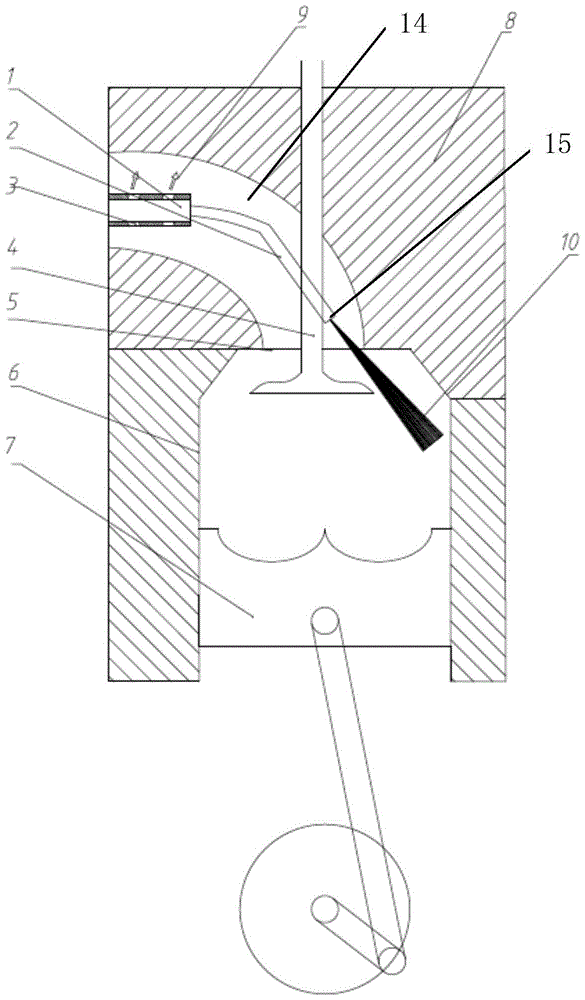

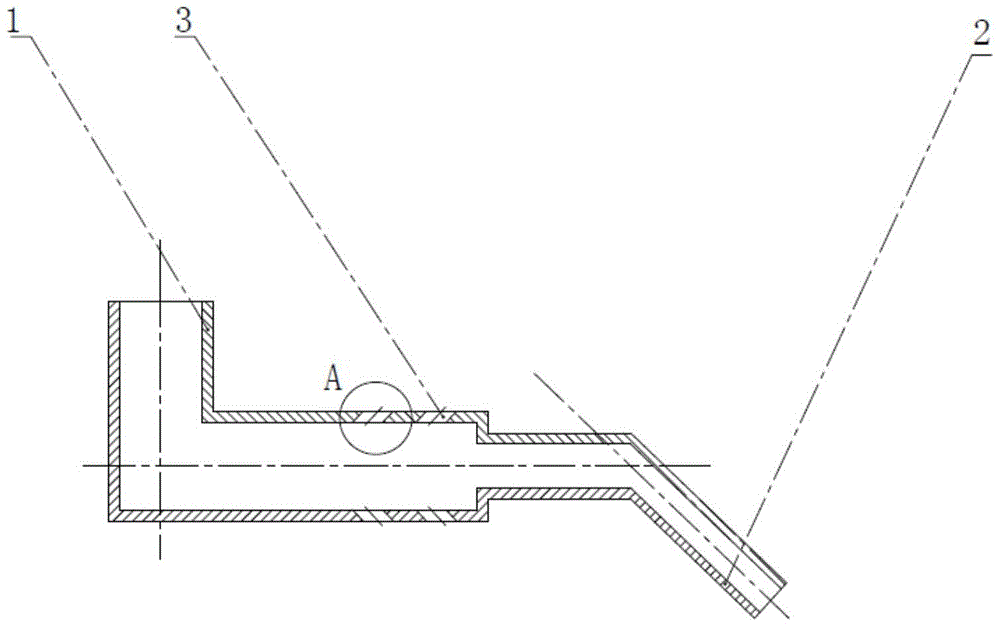

[0020] Implementation Case 1: Combining Figure 1 to Figure 7 , the present invention includes a cylinder head 8 and a cylinder body 6, the cylinder head 8 is provided with a manifold pipe 14, and a large-flow gas nozzle is also installed on the manifold pipe 14, and the large-flow gas nozzle includes an upper half Nozzle 1 and the lower half nozzle 2 fixedly connected with the upper half nozzle 1, the lower half nozzle 2 is an elbow, and the end of the lower half nozzle 2 is provided with a lower half air outlet 15, the gas passes through the lower half The first half of the air outlet 15 is sprayed into the cylinder main body 6 to form a gas pulse 10. The outer surface of the upper half of the nozzle 1 is provided with an upper half of the air outlet 3. The arrangement of the upper half of the air outlet 3 is: along the At least two air outlet groups are arranged in the length direction of the upper half nozzle, and each air hole group has at least four upper half air outlet...

Embodiment example 2

[0024] Embodiment 2: Based on the above embodiment, the present invention can also be: the diameter of the lower nozzle 2 is smaller than the diameter of the upper nozzle 1 , that is, the diameter of the lower nozzle 2 is smaller than that of the upper nozzle 1 .

Embodiment example 3

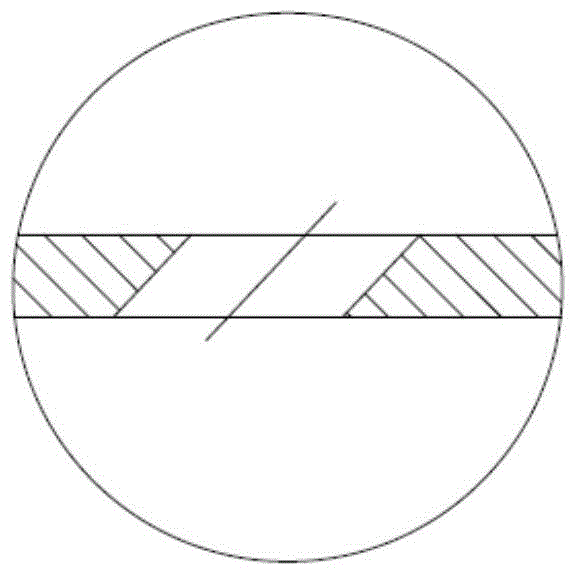

[0025] Embodiment 3: Based on the above-mentioned embodiment and in combination with Fig. 3(A) and Fig. 3(B), the present invention can also be: the clamp between the axis of the upper half of the air outlet 3 and the axis of the upper half of the nozzle 1 The angle is 90° or 45° or 135°. The air outlet 3 of the upper half is a through hole with a diameter of 1-3 mm, connecting the inner cavity of the upper nozzle 1 and the air inlet, and the axis of the upper air outlet 3 of the upper half and the air flow direction of the air inlet At a certain angle, there are currently three design schemes, (1) the axis of the air outlet 3 in the upper half of the upper half is 45° to the axis of the nozzle 1 in the upper half, and the ejected gas pulse 9 is consistent with the incoming flow direction of the intake air; (2) ) The axis of the air outlet 3 in the upper half of the upper half is 135° to the axis of the nozzle 1 in the upper half, and the ejected gas pulse 9 is opposite to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com