Backlight unit

A technology of backlight unit and light source, applied in optical elements, light guides, optics, etc., can solve the problems of diffuse light generation, brightness deterioration, deformation, and bending of the backlight unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

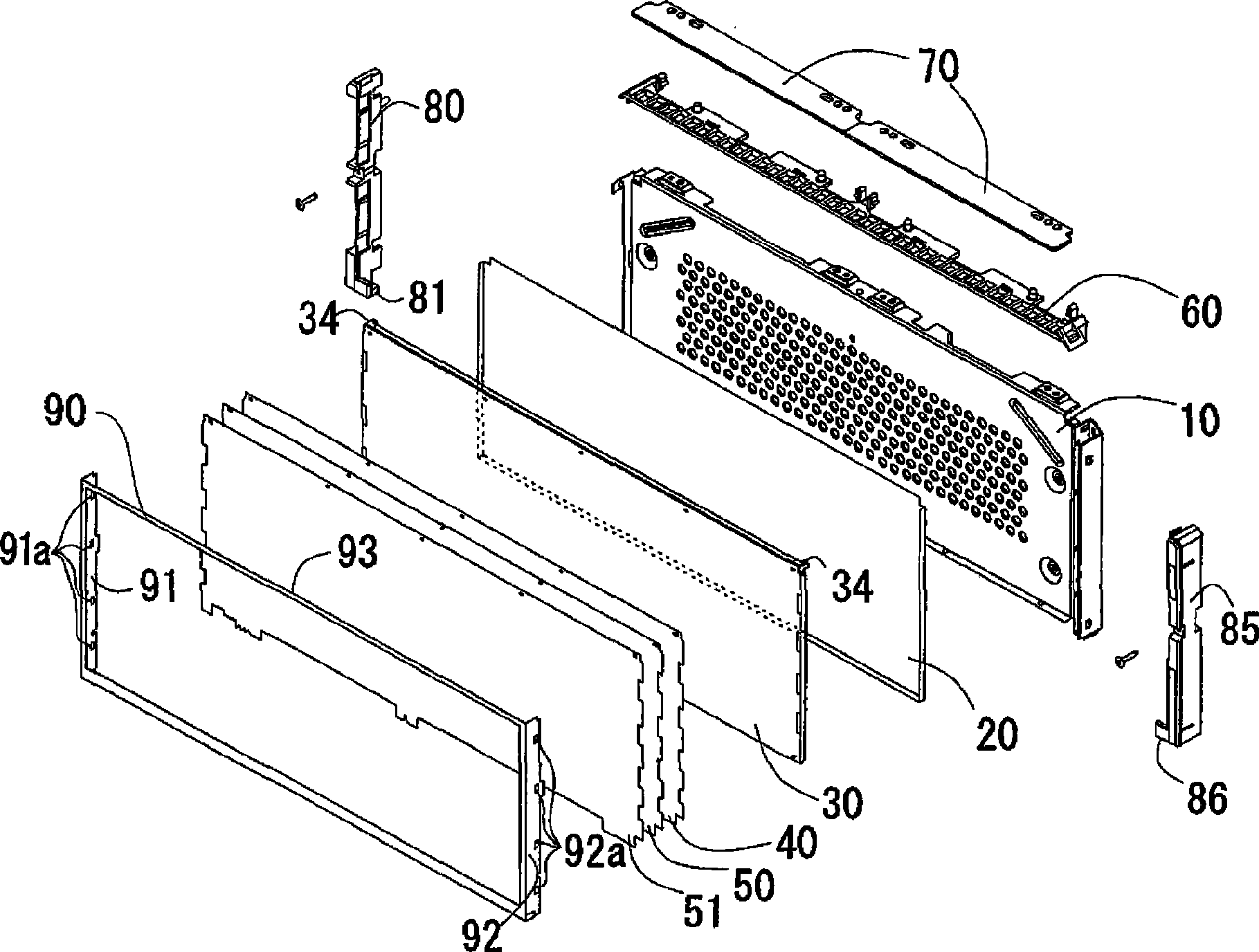

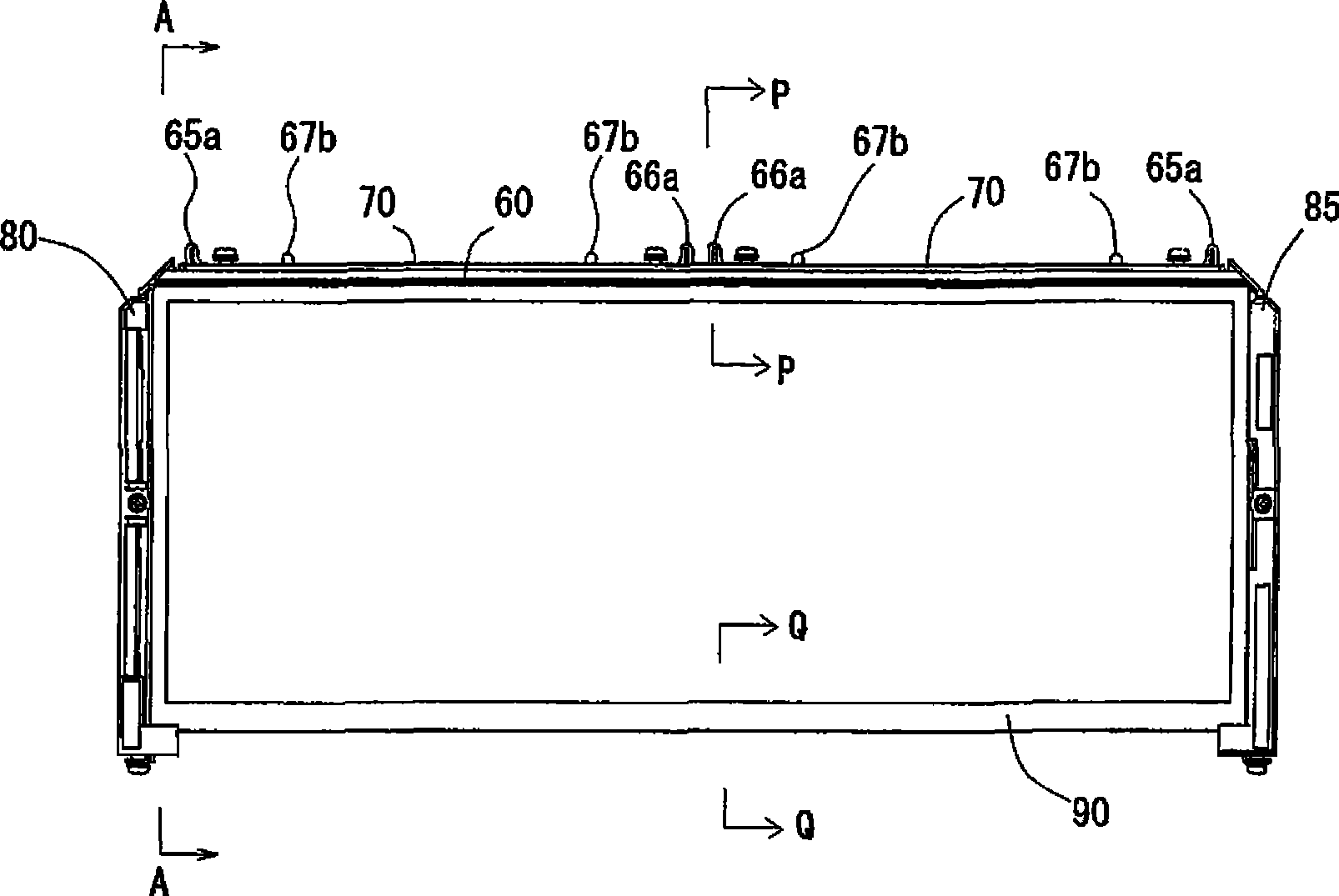

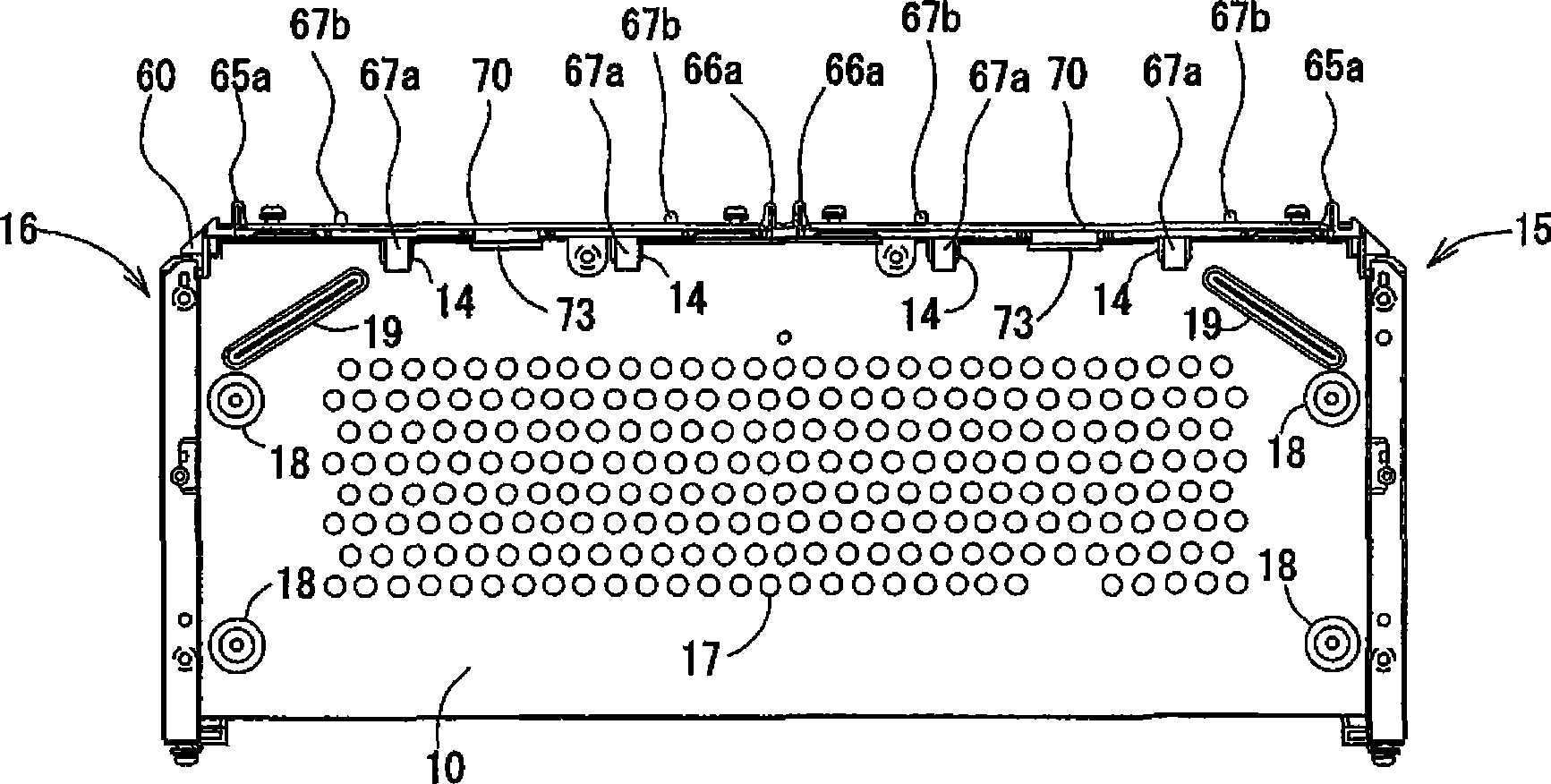

[0081] The present invention will be described in detail below with reference to the accompanying drawings. figure 1 is an exploded perspective view of the backlight unit 1 according to one embodiment of the present invention. Figure 2 to Figure 7 These are a front view, a rear view, a left view, a right view, a plan view and a bottom view of the backlight unit 1, respectively. The backlight unit 1 includes a shield cover (support plate) 10, a reflection sheet 20, a light guide (light guide plate) 30, a diffusion sheet 40, a vertical eye prism sheet 50, a horizontal eye prism sheet 51, an upper holder (maintaining member) 60, A printed circuit board assembly 70 , a left holder 80 , a right holder 85 , and a TFT holder (liquid crystal panel holding member) 90 . In the backlight unit 1 , the reflection sheet 20 , the light guide 30 , the diffusion sheet 40 , the vertical eye prism sheet 50 and the horizontal eye prism sheet 51 are sequentially stacked in the front of the shield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com