Vertical wind power generator with motor startup mode

A technology of wind power generator and starting method, which is applied in the direction of controlling the generator, controlling the generator and electrical components through the change of the magnetic field, and can solve the problems such as the difficulty of starting the generator, so as to improve the static stability, reduce the degree of failure loss, The effect of improving transient stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

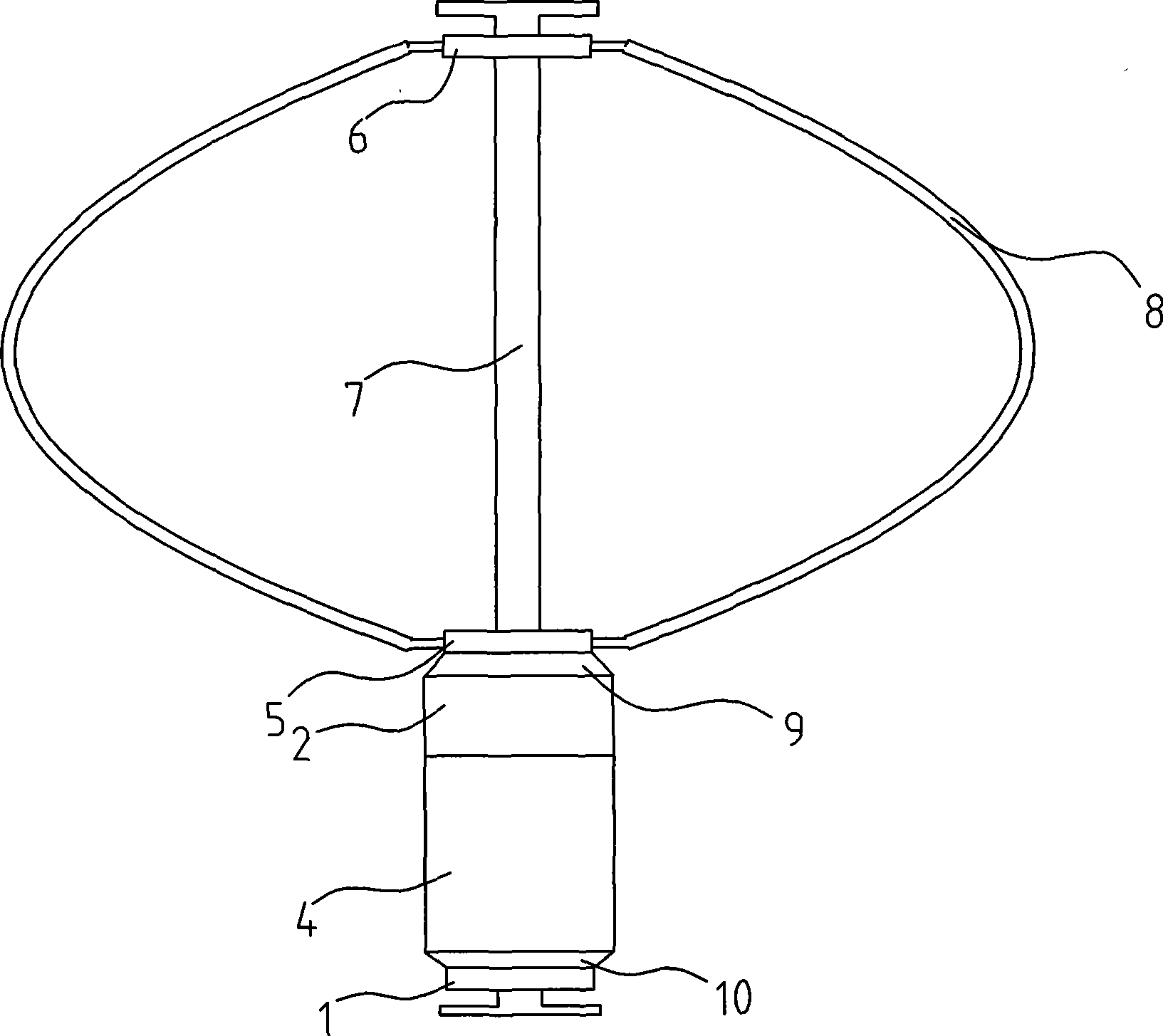

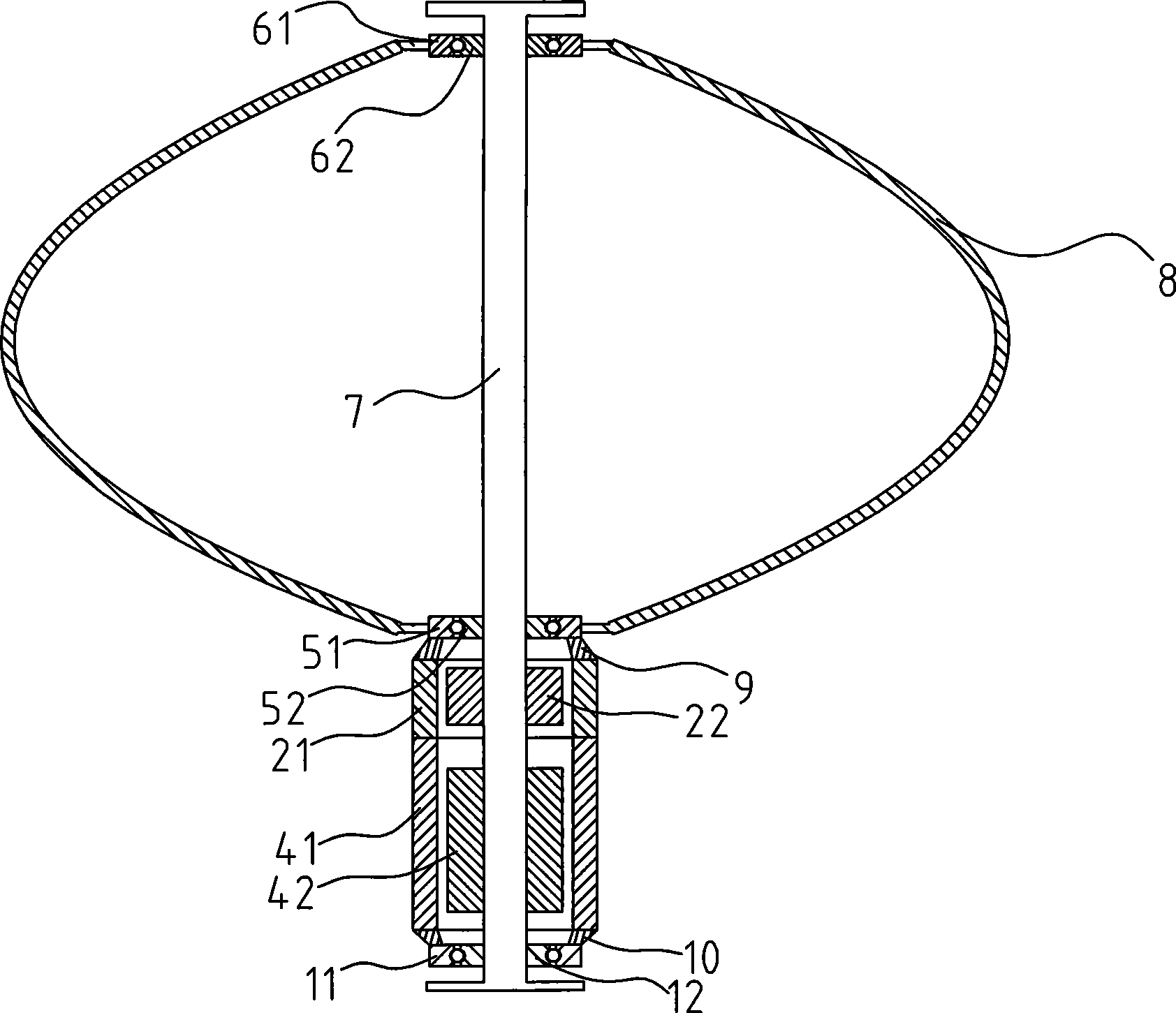

[0041] Such as figure 1 , 2 As shown, a vertical wind power generator with a motor starting method includes a tower column and a vertical wind power generation unit located on the tower column 7, and the vertical wind power generation unit includes a first bearing 1, a generator 4, a second bearing 5. The third bearing 6 and the blade 8. The first bearing 1 includes a first bearing outer ring 11 and a first bearing inner ring 12. The second bearing 5 includes a second bearing outer ring 51 and a second bearing inner ring 52. The third bearing 6 includes a first bearing outer ring 51 and a second bearing inner ring 52. Three bearing outer rings 61 and a third bearing inner ring 62 . The first bearing inner ring 12 , the second bearing inner ring 52 and the third bearing inner ring 62 are fixedly sleeved on the tower column 7 . The lower end of the blade 8 is fixedly connected to the second bearing outer ring 51 , and the upper end of the blade 8 is fixedly connected to the t...

Embodiment 2

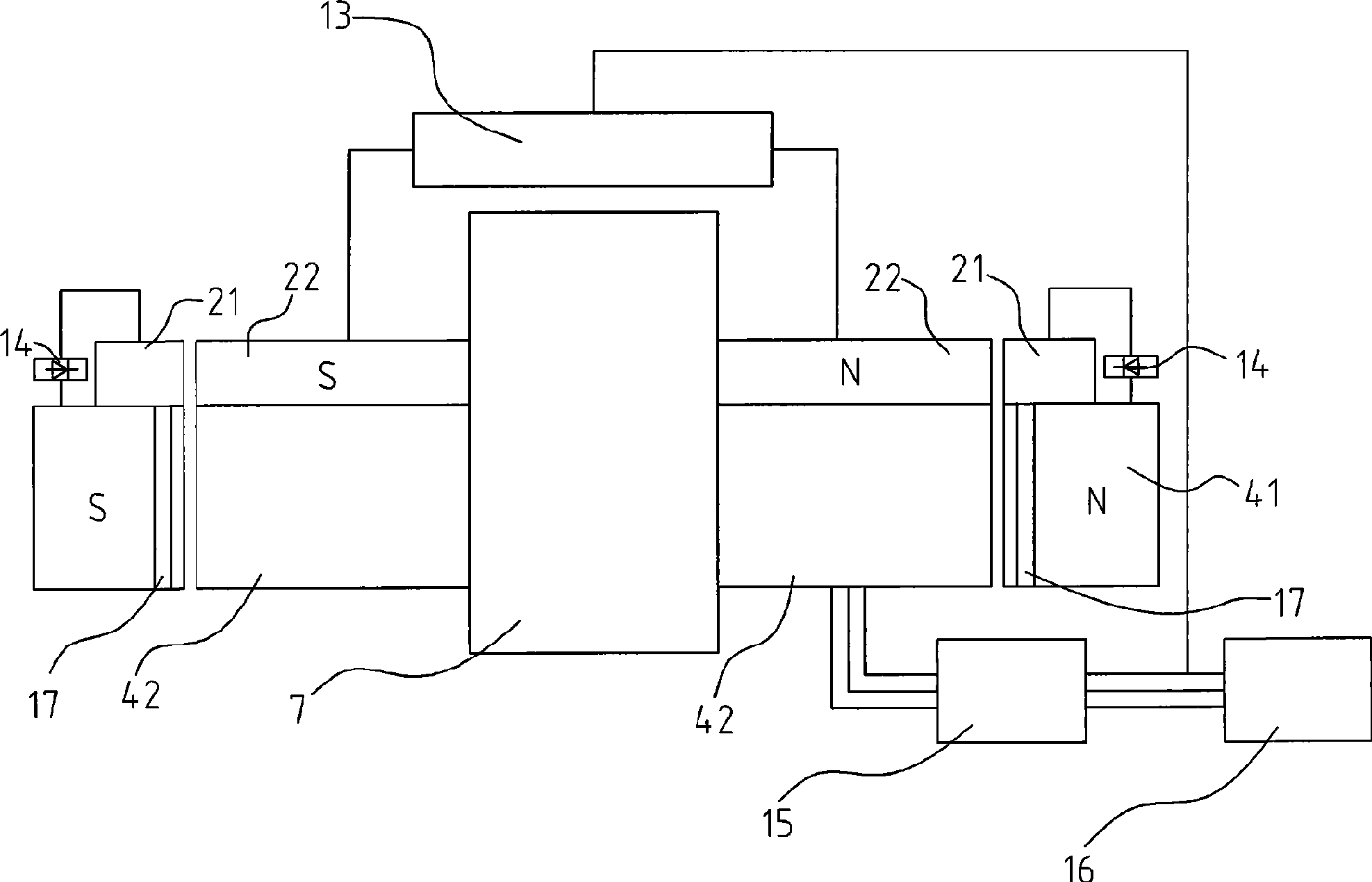

[0050] Such as Figures 4 to 6 As shown, a vertical wind power generator with a motor starting method includes a tower column 7 and two vertical wind power generation units located on the tower column 7, and the two vertical wind power generation units are vertically distributed up and down. The vertical wind power generation unit includes a first bearing 1 , a generator 4 , a second bearing 5 , a third bearing 6 , and blades 8 . The first bearing 1 includes a first bearing outer ring 11 and a first bearing inner ring 12. The second bearing 5 includes a second bearing outer ring 51 and a second bearing inner ring 52. The third bearing 6 includes a first bearing outer ring 51 and a second bearing inner ring 52. Three bearing outer rings 61 and a third bearing inner ring 62 . The lower end of the blade 8 is fixedly connected to the second bearing outer ring 51 , and the upper end of the blade 8 is fixedly connected to the third bearing outer ring 61 . The generator 4 is an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com