Method and apparatus for inspecting defect of laminated film

A technique for defect inspection, lamination of films, used in measuring devices, transportation and packaging, testing moving boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

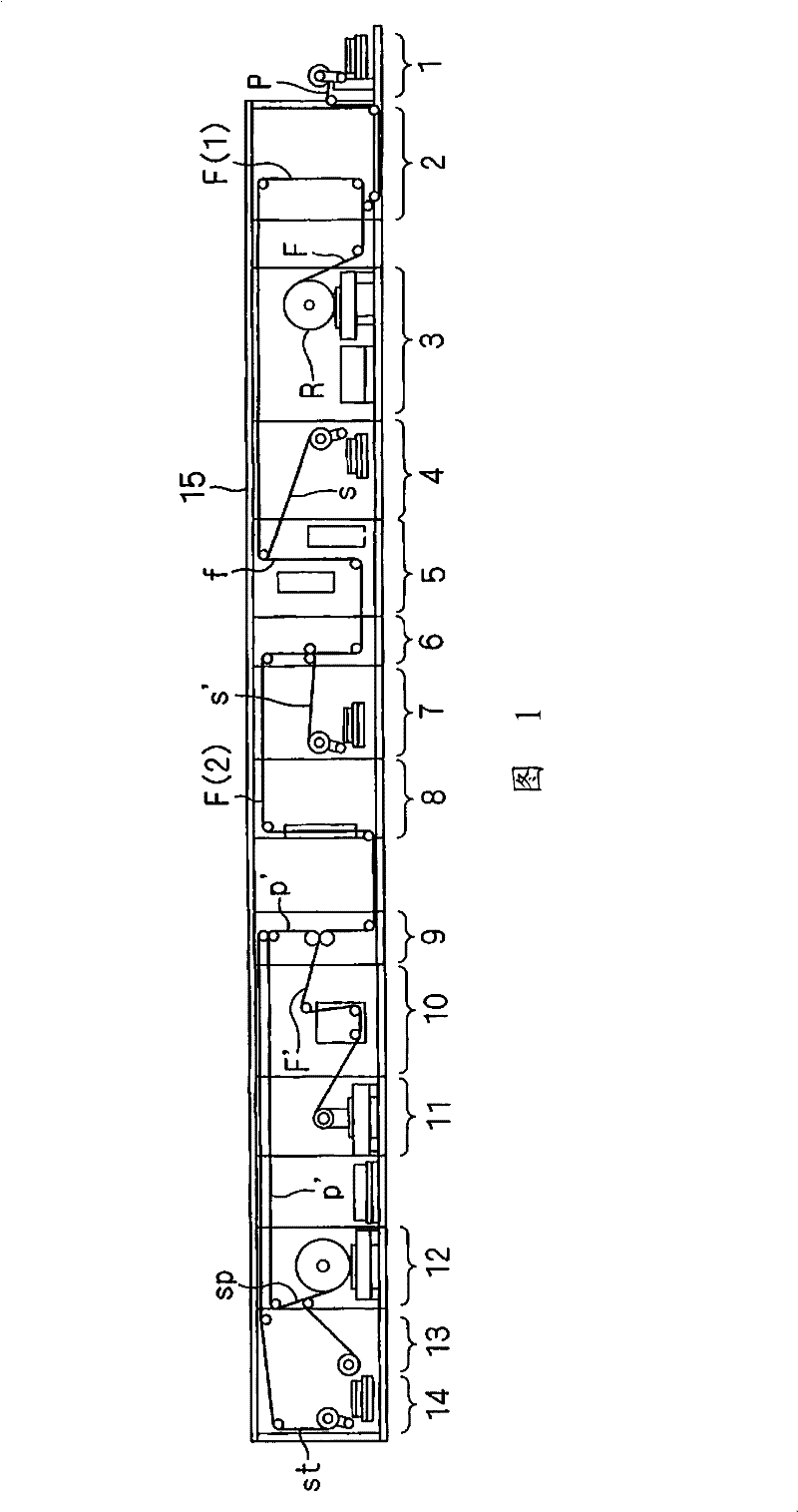

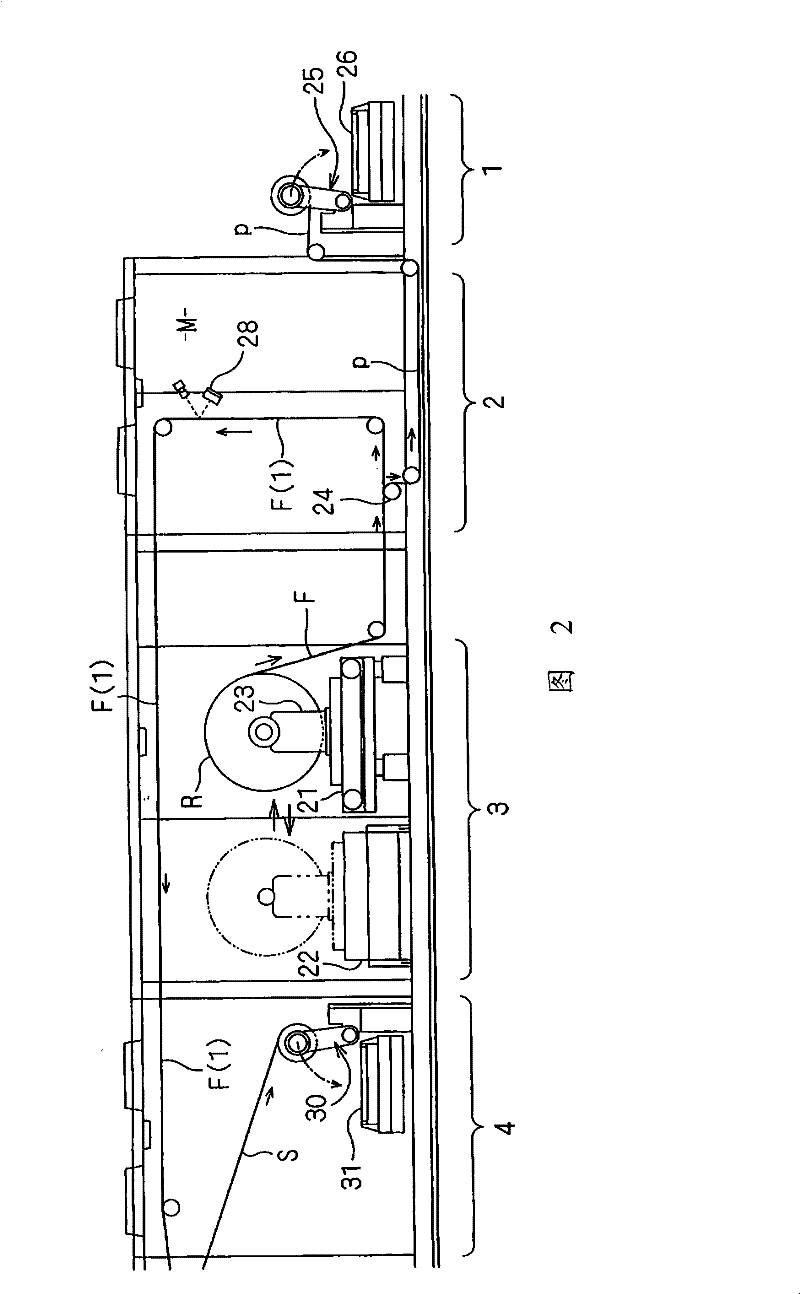

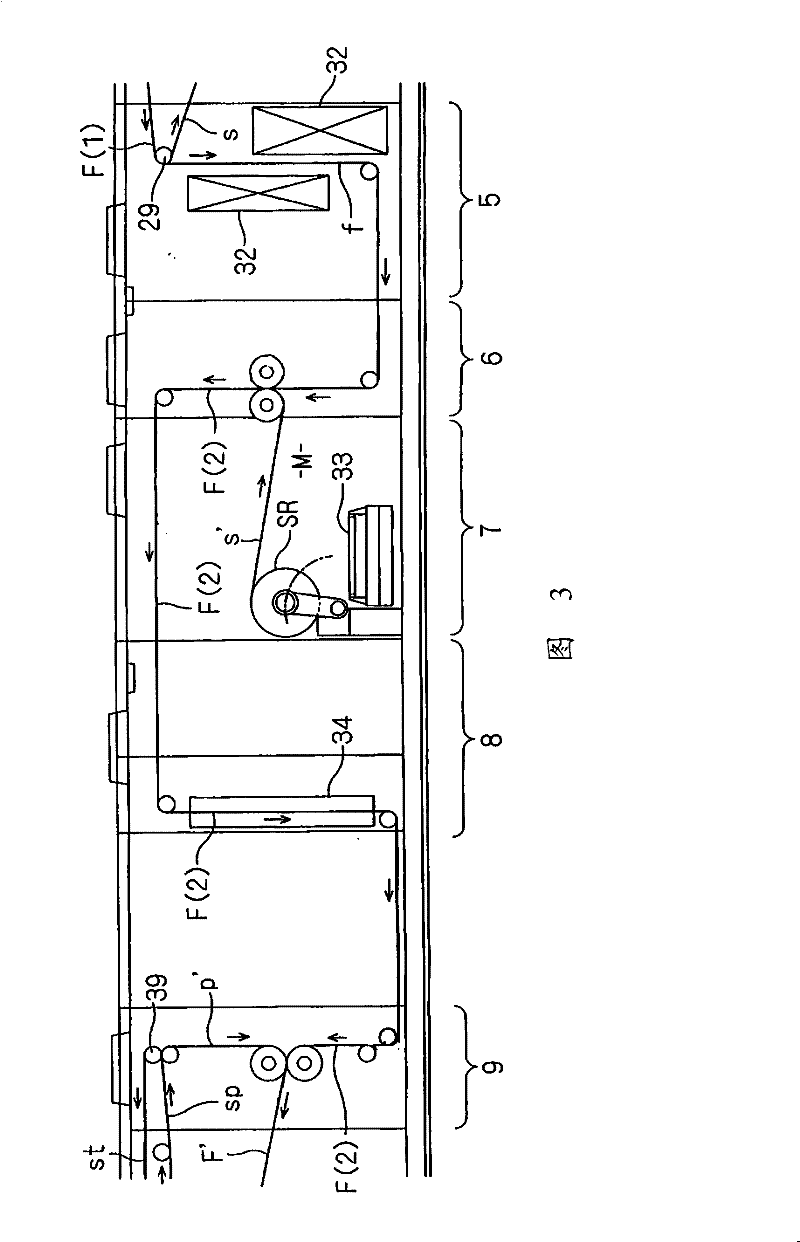

[0052] Next, an embodiment of the present invention will be described with reference to the drawings.

[0053] figure 1 Represents the whole defect inspection device implementing the method of the present invention, Figure 2 ~ Figure 4 Each part of the defect inspection device is shown enlarged. In this defect inspection device, from figure 1 On the right side in the middle, the protective film recovery unit 1, the first inspection unit 2, the laminated membrane supply unit 3, the separation membrane recovery unit 4, the second inspection unit 5, the separation membrane sticking unit 6, and the separation membrane supply unit are arranged in a row. 7. Marking section 8, protective film sticking section 9, data recording processing section 10, laminated film recovery section 11, protective film supply section 12, protective film edge recovery section 13 and protective film separation membrane recovery section 14, and, Each part except the protective film recovery part 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com