A cylindrical insulating riser base

A thermal insulation riser and cylindrical technology, which is applied in the direction of casting molding equipment, casting molds, cores, etc., can solve the problems of easy-cut sheet thickness limitation, limited process yield, and lack of heat insulation effect, etc., to reduce material Cost, good heat insulation effect, effect of improving refractoriness and heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

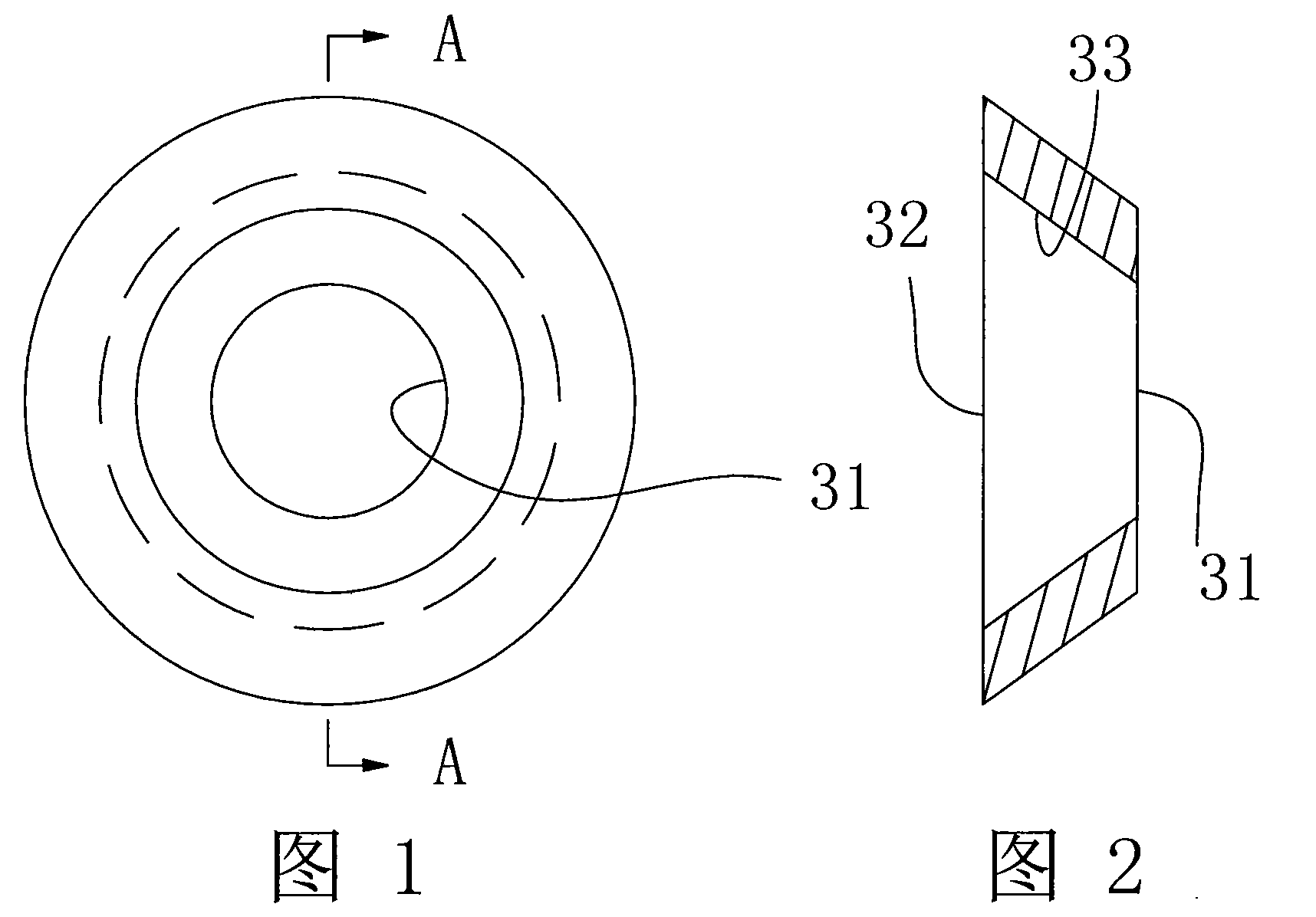

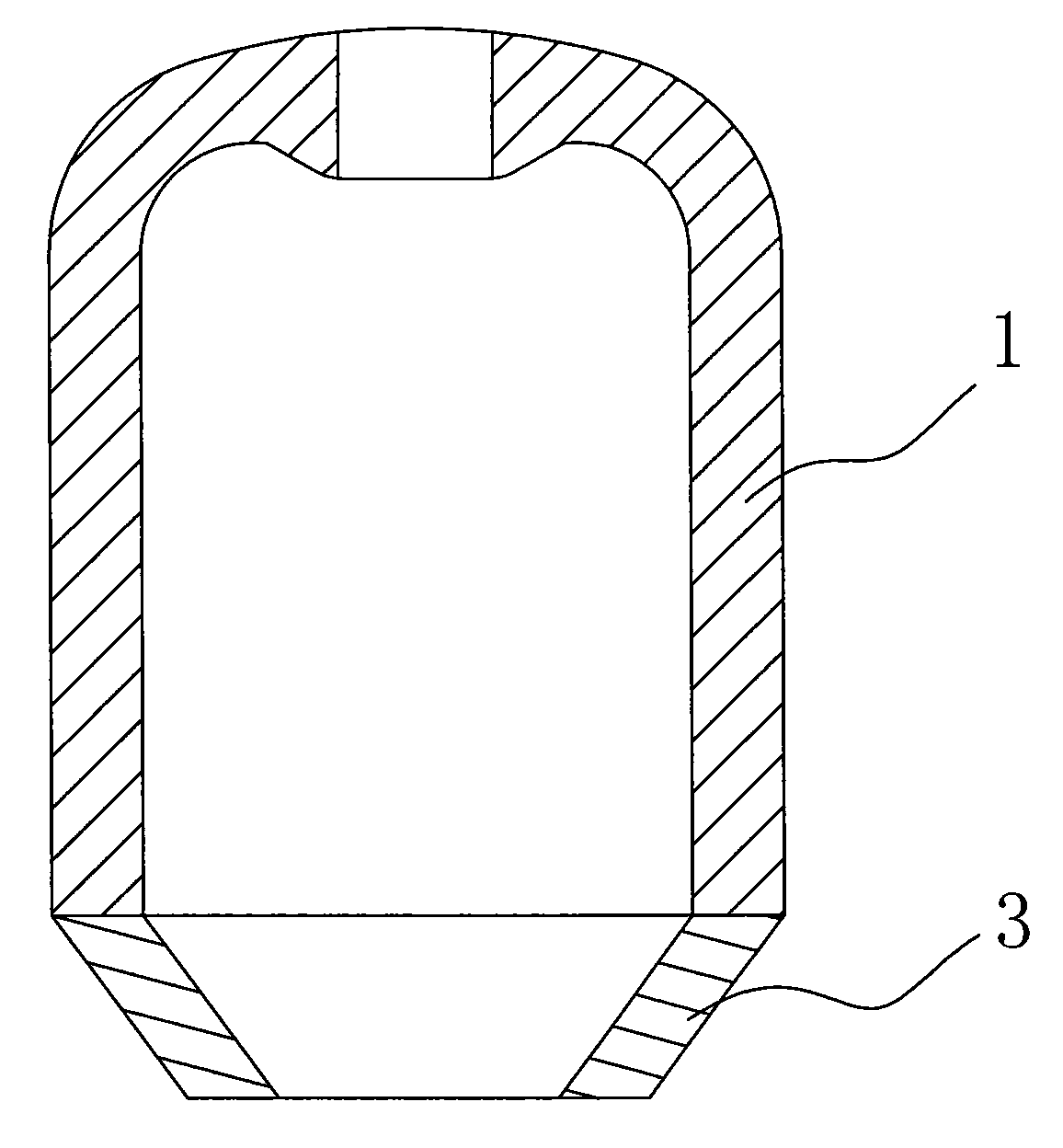

[0030] Such as figure 1 , figure 2 The base of a cylindrical thermal insulation riser shown is in the shape of a tapered sleeve with an inner conical surface 33 as a whole, the upper opening 32 of the inner conical surface 33 matches the bottom of the cylindrical thermal insulation riser, and the lower opening 32 of the inner conical surface 33 The radius of the opening 31 is less than the radius of the upper opening 32; the cone angle of the inner conical surface 33 is 90°, and the radius of the upper opening 32 of the inner conical surface 33 is twice the radius of the lower opening 31; it is an equal wall thickness structure.

[0031] The base is made as follows:

[0032] 30 kg of paper slag from waste paper, 40 kg of slag cotton, 40 kg of cornstarch, and coarse quartz powder or quartz stone with a fineness of 600-900 mesh are produced by water method and screened through a 600-mesh screen. 600-700 kg of quartz waste powder, according to the above proportions. Add appro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com