Hoist double-trolley electric hoist

An electric hoist, trolley-type technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of poor braking effect and low safety performance, achieve the effect of small space, improve safety, and meet the effect of safe braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

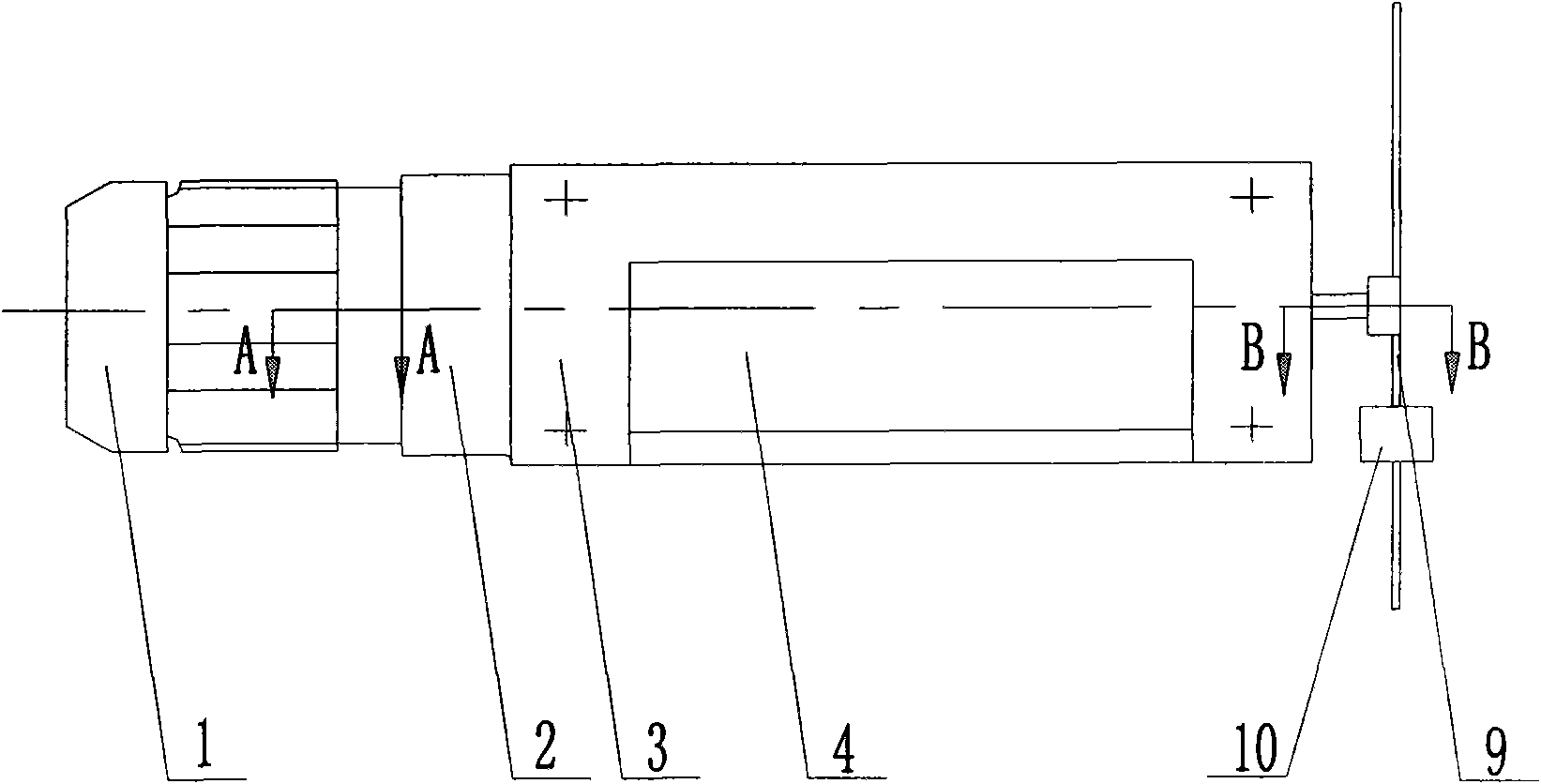

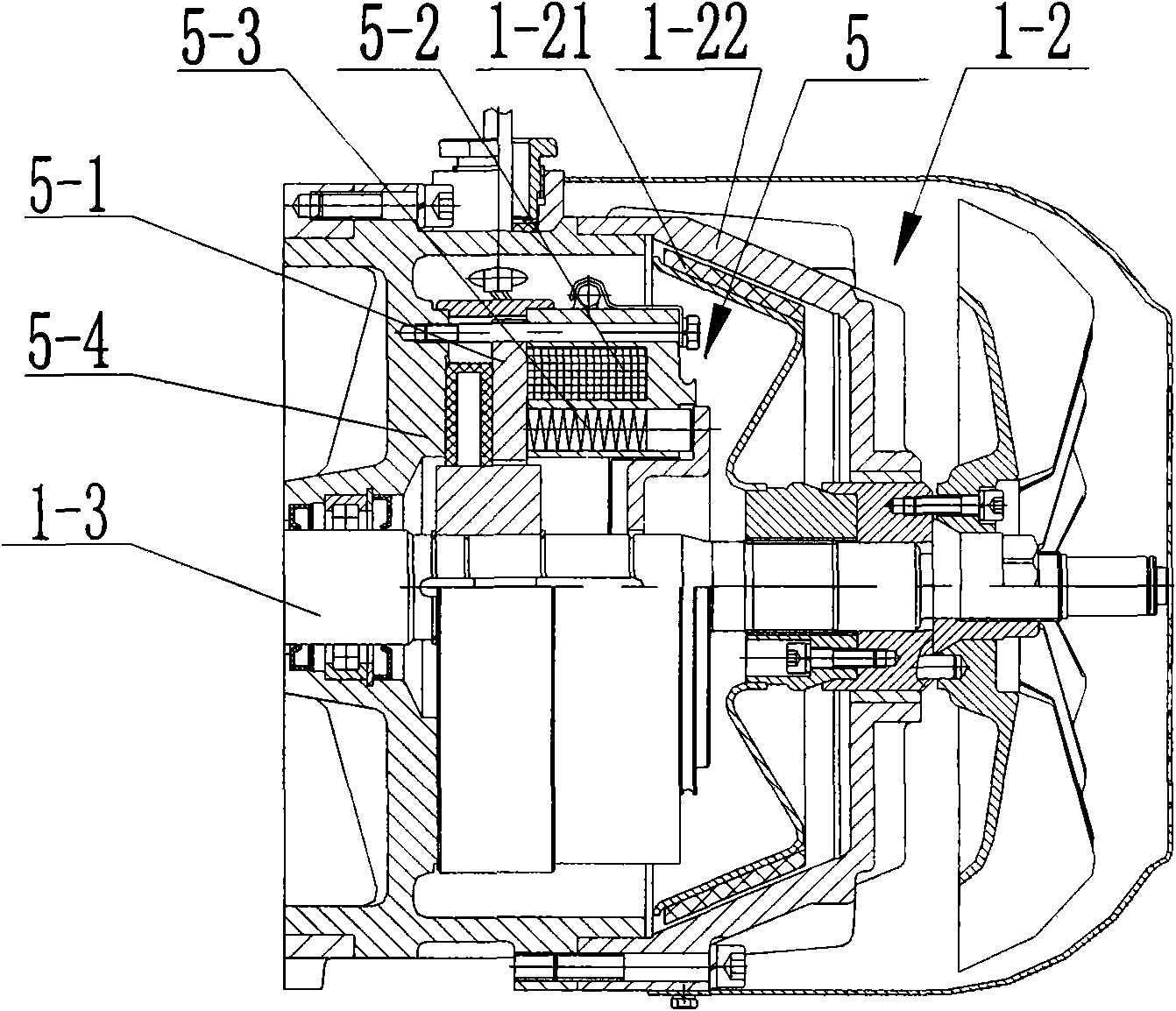

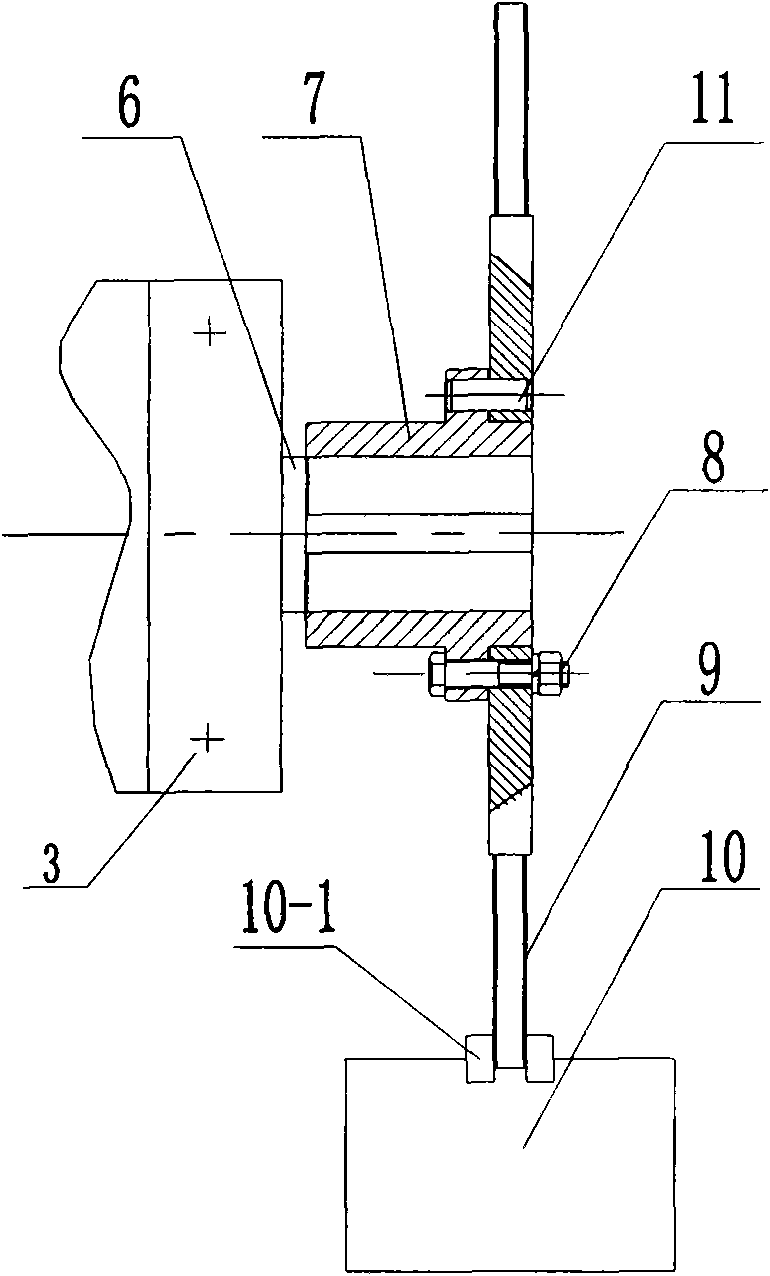

[0018] see Figure 1 to Figure 3 , a hoist double trolley type electric hoist, including a motor 1 with a brake, a reducer 2 installed on the output shaft of the motor, a bracket 3 and a reel device 4 installed on the bracket, wherein the built-in brake of the motor It is the first brake 1-2, which uses a conical AC brake. Its working principle: when the power is turned on, the motor shaft drives the first brake for axial displacement at the moment of rotation, the first brake is opened, and after the power is cut off, the motor shaft returns to its original position under the action of the pressure spring, and the brake discs 1-21 and The brake seat 1-22 generates friction, thereby playing the role of braking. The braking torque varies with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com