A liquid fertilizer containing biogas slurry and usage method thereof

A technology of liquid fertilizer and biogas slurry, which is applied in the field of liquid fertilizer to achieve the effect of rich and perfect nutrient composition, sufficient source of materials, and enlarged application area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

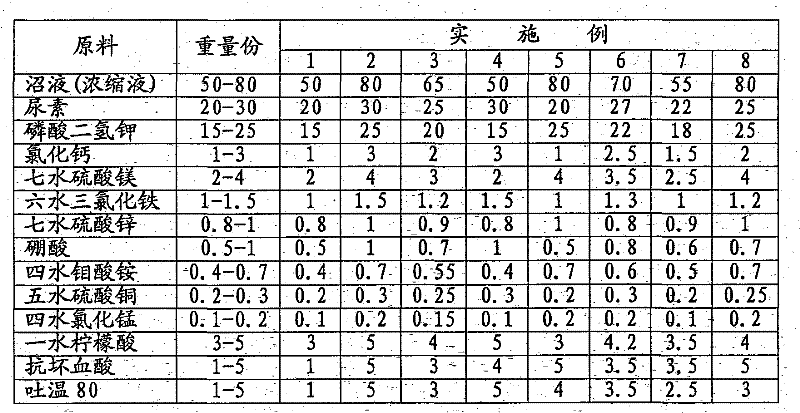

[0018] Embodiment 1 (with reference to the raw material corresponding to Embodiment 1 and parts by weight thereof in the table):

[0019] Get 50 parts by weight (the same below) biogas slurry concentrate, 20 parts of urea, 15 parts of KH 2 PO 4 , 1 part of CaCl 2 , 2 parts of MgSO 4 ·7H 2 O was put into the biogas slurry to fully dissolve and mix well, and then 1 part of FeCl 3 ·6H 2 O, 0.8 parts of ZnSO 4 ·7H 2 O, 0.5 parts of H 3 BO 3 , 0.4 parts (NH 4 ) 6 Mo 7 o 24 4H 2 O, 0.2 parts of CuSO 4 ·5H 2 O, 0.1 part of MnCl 2 4H 2 0, 3 parts of citric acid (monohydrate), 1 part of ascorbic acid are respectively dissolved in the solution, add 1 part of surfactant polysorbate 80, namely Tween 80, make liquid fertilizer stock solution after fully mixing, then use the stock solution weight 500-1000 times diluted with industrial water, with 1% H 2 SO 4 Or adjust the pH to 6 with 1% HCl to become the nutrient solution for soilless cultivation. Consider C1 - Excess...

Embodiment 2

[0020] Embodiment 2 (with reference to embodiment 2 corresponding raw material and weight portion thereof in the table):

[0021] Take 80 parts of biogas slurry concentrate, then add 30 parts of urea, 25 parts of KH 2 PO 4 , 3 parts of CaCl 2 , 40 parts of MgSO 4 ·7H 2 O was put into the biogas slurry to fully dissolve and mix well, and then 1.5 parts of FeCl 3 ·6H 2 O, 1 part ZnSO 4 ·7H 2 O, 1 H 3 BO 3 , 0.7 parts (NH 4 ) 6 Mo 7 o 24 4H 2 O, 0.3 parts of CuSO 4 ·5H 2 O, 0.2 parts of MnCl 2 4H 2 0, 5 parts of citric acid (monohydrate), 5 parts of ascorbic acid melt into the solution respectively, finally add 80 parts of surfactant polysorbates (Tween 80), make liquid fertilizer stock solution after fully mixing, and use The stock solution is diluted with 1000-2000 times the weight of industrial water, adjusted to pH 7 with 1% HCl, and then becomes a directly applicable foliar fertilizer for spraying.

Embodiment 3

[0022] Embodiment 3 (with reference to embodiment 3 corresponding raw material and weight portion value thereof in the table):

[0023] Take 65 parts of biogas slurry concentrate, then add 25 parts of urea, 20 parts of KH 2 PO 4 , 2 parts of CaCl 2 , 3 parts of MgSO 4 ·7H 2 O was put into the biogas slurry to fully dissolve and mix well, and then 1.2 parts of FeCl 3 ·6H 2 O, 0.9 parts of ZnSO 4 ·7H 2 O, 0.7 parts of H 3 BO 3 , 0.55 parts (NH 4 ) 6 Mo 7 o 24 4H 2 O, 2.5 parts of CuSO 4 ·5H 2 O, 1.5 parts of MnCl 2 4H 2 0, 4 parts of citric acid (monohydrate), 3 parts of ascorbic acid are dissolved in the solution respectively, add 3 parts of surfactant polysorbate 80 namely Tween 80, make the liquid fertilizer that pH is 7-8.5 after fully mixing Stock solution, short-term storage for future use. Dilute and adjust pH to 6.5 temporarily as needed just before application. Although commonly used chemical fertilizers and organic fertilizers are mostly alkaline fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com