Thermoplastic polyester elastomer closed-cell micro-foaming material, preparing method thereof and vibration absorbing usage

A thermoplastic polyester and elastomer technology, applied in coatings and other directions, can solve the problems of low service life, difficult to meet the requirements of shock absorption, poor shock absorption effect, etc., to achieve high yield, good shape memory function, and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]

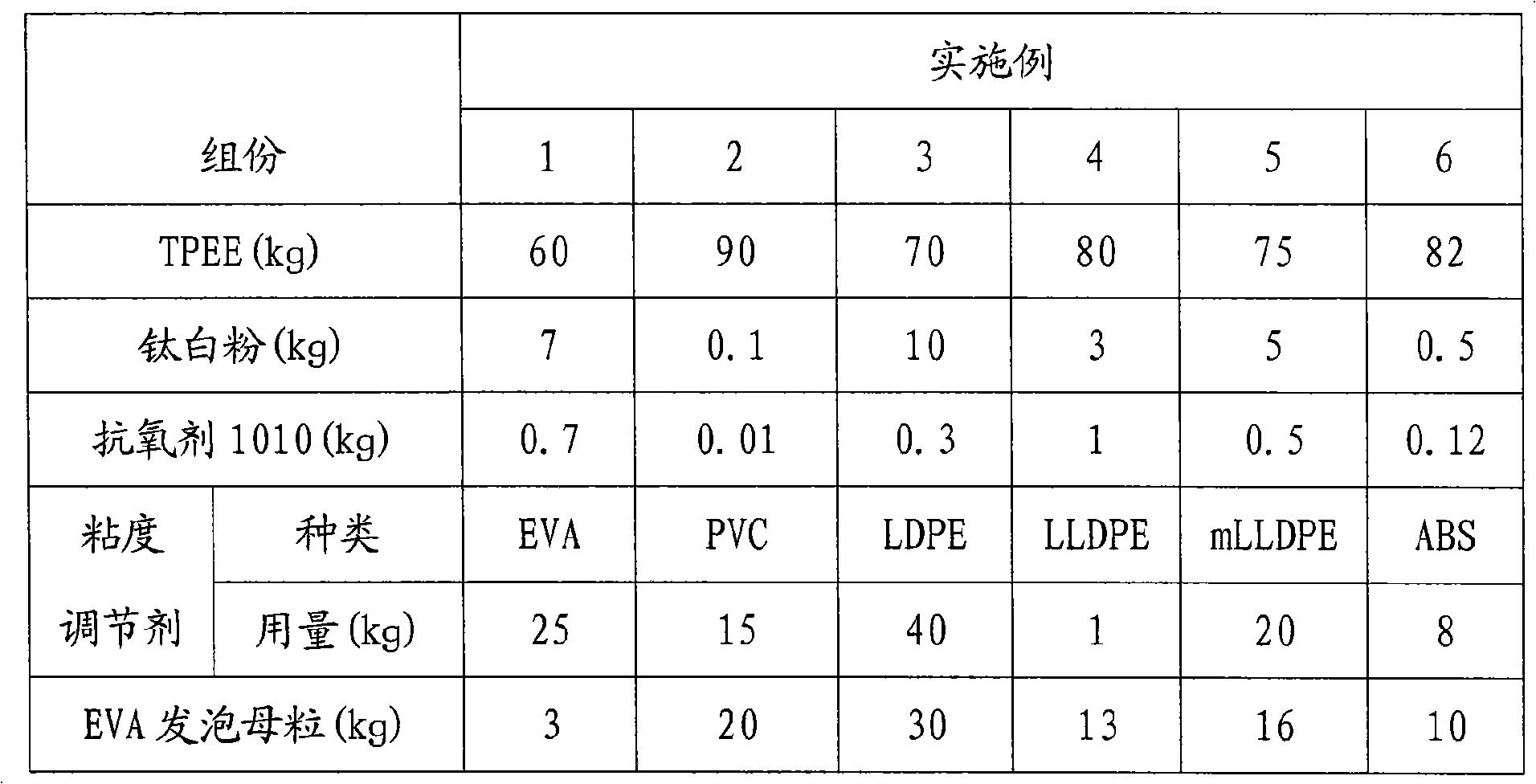

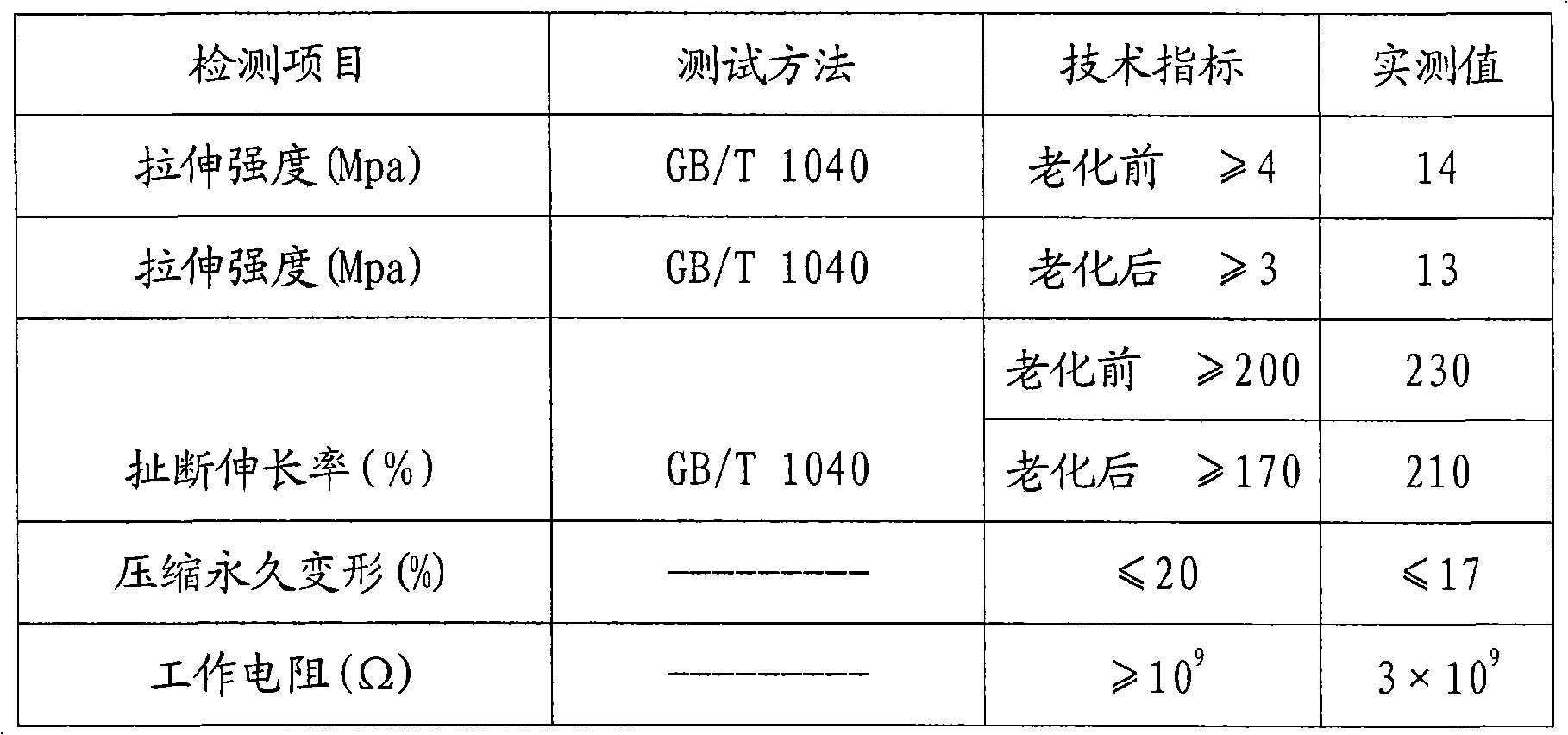

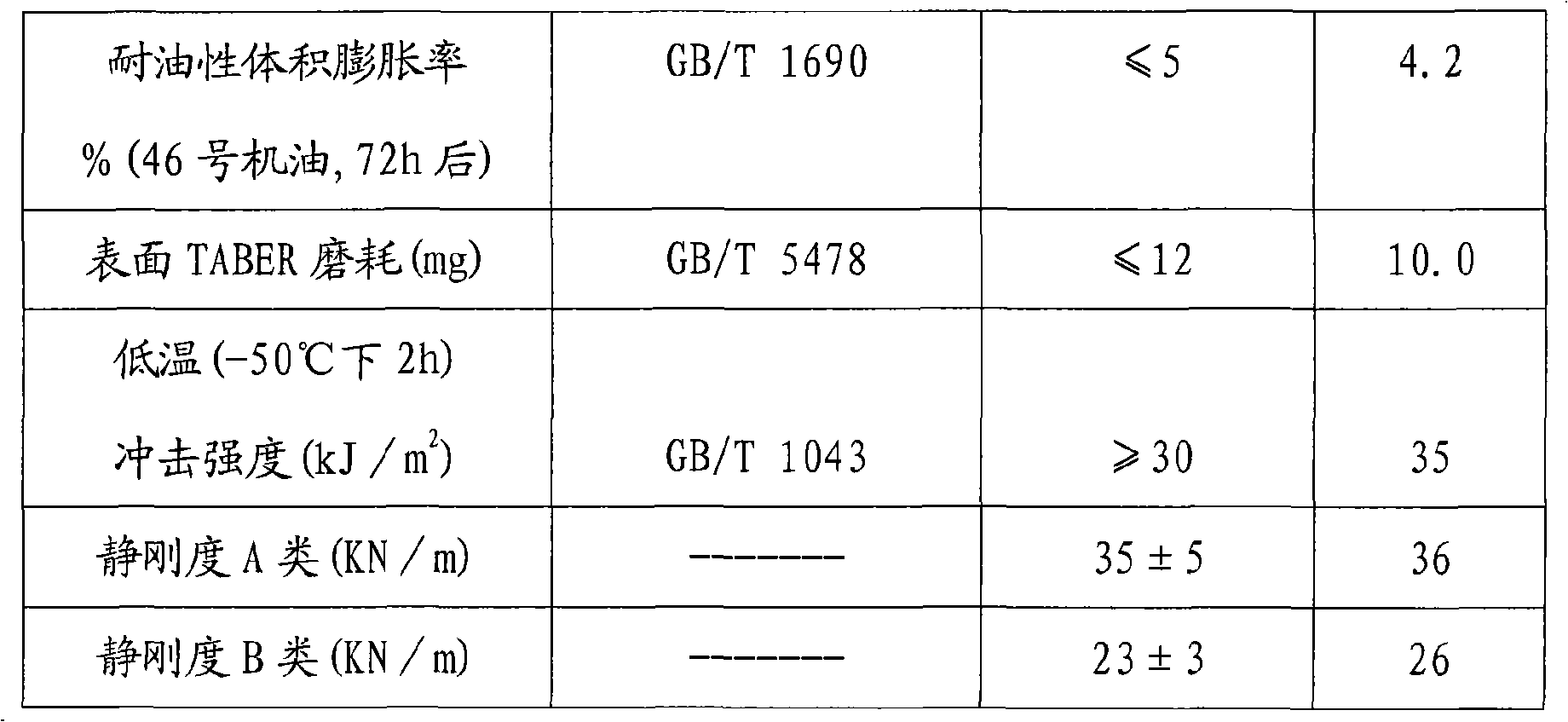

[0047] Embodiments 1-6 are respectively a kind of TPEE closed-cell micro-foaming material, and the composition of raw materials for making active ingredients is as shown in the above table.

[0048] The preparation method is to mix and granulate TPEE, titanium dioxide, antioxidant 1010, and a viscosity modifier to obtain a base material, and then mix the base material with EVA foaming master batches for injection molding and foaming to obtain a product. The obtained TPEE closed-cell micro-foaming material is used for processing shock-absorbing pads or / and shock-absorbing pads, especially rail tie pads and sleeper pads.

[0049] As the TPEE closed-cell micro-foaming material processing technology of embodiment 1 is:

[0050] (1) Prepare base material:

[0051] TPEE, titanium dioxide, antioxidant 1010, viscosity regulator mixing → twin-screw extrusion granulation → base material;

[0052] (2) Foaming:

[0053] The base material is mixed with EVA foam masterbatch →...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com