Reinforcing steel bar connecting device

A connection method and connection device technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of difficult screw connection strength, high equipment requirements, and large influence on the shape of steel bars, and achieve simple and convenient construction technology and a high degree of industrialization , The effect of simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

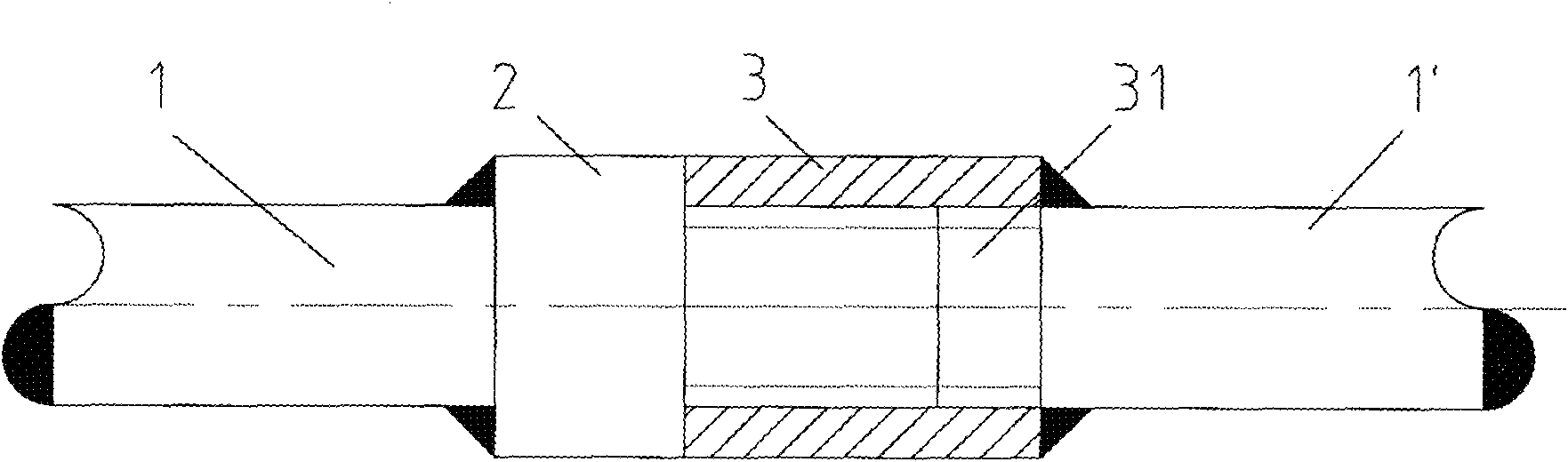

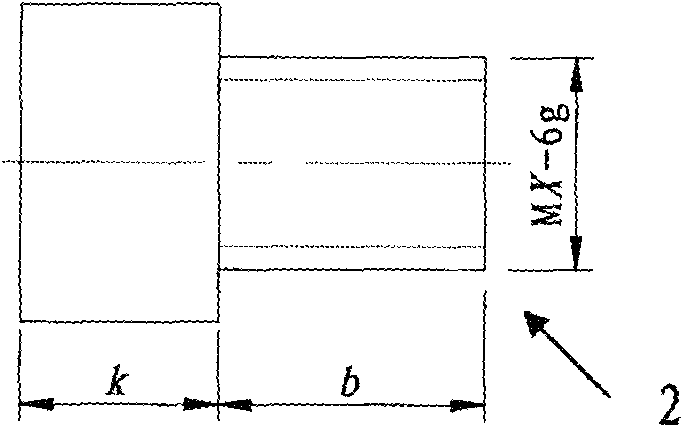

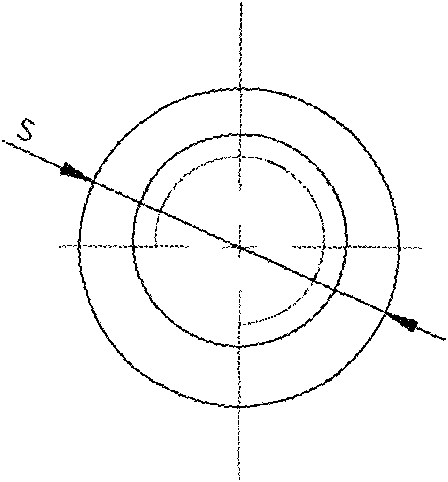

[0046] In this embodiment, a HRB335 type steel bar with a diameter of Φ20 needs to be extended with another steel bar of the same model and the same diameter. see figure 1 , this steel bar connection device includes a bolt connection pair for connecting two steel bars 1, 1' to be connected, the bolt connection pair includes a bolt 2 and a sleeve 3, and the bolt 2 and the sleeve 3 correspond to each other , and the bolt 2 and the sleeve 3 are respectively welded to the corresponding steel bars 1 and 1 ′, and the bolt 2 and the sleeve 3 are screwed together. In order to make the connection between the sleeve 3 and the reinforcing bar 1 ' fixed, a sleeve bottom screw rod 31 can be set at the inside of the sleeve 3 and the side connected with the reinforcing bar. As mentioned above, the external thread of the sleeve back cover screw 31 matches the internal thread of the sleeve.

[0047] This steel bar connection method adopting the above-mentioned steel bar connection device com...

Embodiment 2

[0074] see Figure 8 The difference between the reinforcing bar connecting device and method in the present embodiment and the reinforcing bar connecting device method in Embodiment 1 is that the bolt connecting pair includes two bolts 2, 2' and a sleeve 3, and the bolts 2, 2' Corresponding to the internal threads at both ends of the sleeve 3 respectively, and the bolts 2, 2' are welded to the corresponding steel bars 1, 1' respectively, and the bolts 2, 2' are respectively connected to the sleeve 3 Screw-in connection at both ends.

[0075] In addition, since the sleeve 3 is not welded together with the reinforcing bars 1, 1', the sleeve back cover screw can be unnecessary inside the sleeve.

Embodiment 3

[0077] see Figure 9 The difference between the reinforcing bar connecting device and method in the present embodiment and the reinforcing bar connecting device and method in Embodiment 1 is that: the bolt connecting pair includes a bolt 2 and two sleeves 3, 3 ', and the bolt 2 is two stud bolts whose ends are respectively corresponding to the sleeves 3, 3', and the sleeves 3, 3' are welded to the corresponding steel bars 1, 1' respectively, and the two ends of the bolt 2 are respectively connected to the The sleeves 3 and 3' are screwed together.

[0078] In addition, since the sleeves 3, 3' are welded together with the reinforcing bars 1, 1', the sleeves 3, 3' are provided with sleeve back-sealing screws 31, 31' to reinforce the sleeve 3 or 3' and the reinforcing bars. 1 or 1' for connection strength and stability.

[0079]In summary, the steel bar connection method of the present invention has the advantages of reliable connection strength, high degree of industrializatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com