Multi-head equal-wall thickness anticorrosive screw pump

A technology of equal-wall-thickness screw pumps, applied in pumps, rotary piston pumps, pumps with flexible working elements, etc., can solve the problems of poor corrosion resistance of the stator shell, small displacement of the screw pump, and small diameter of the inner hole of the rotor, etc. problems, to achieve the effect of prolonging the inspection period of the pump, prolonging the service life and reducing the maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

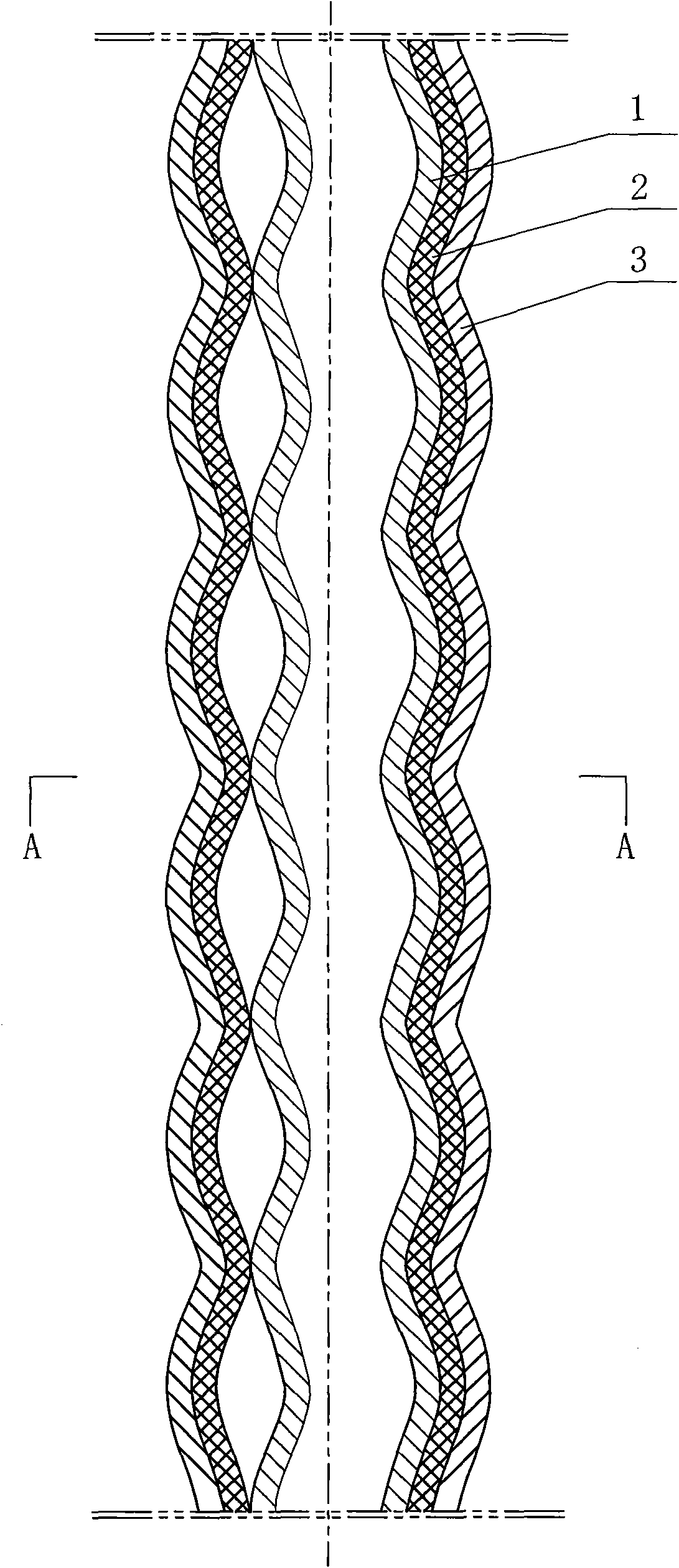

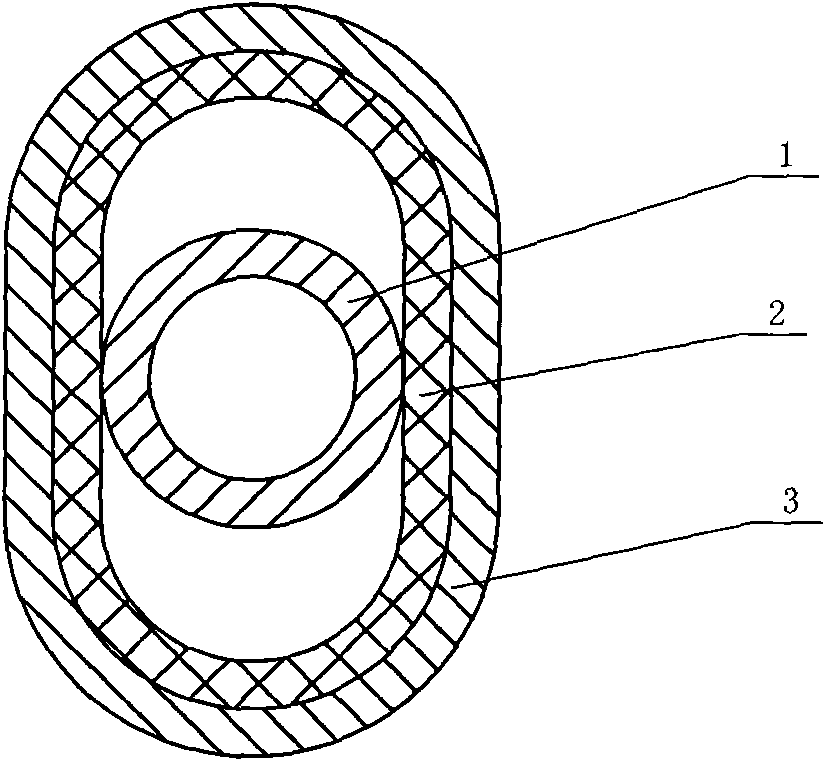

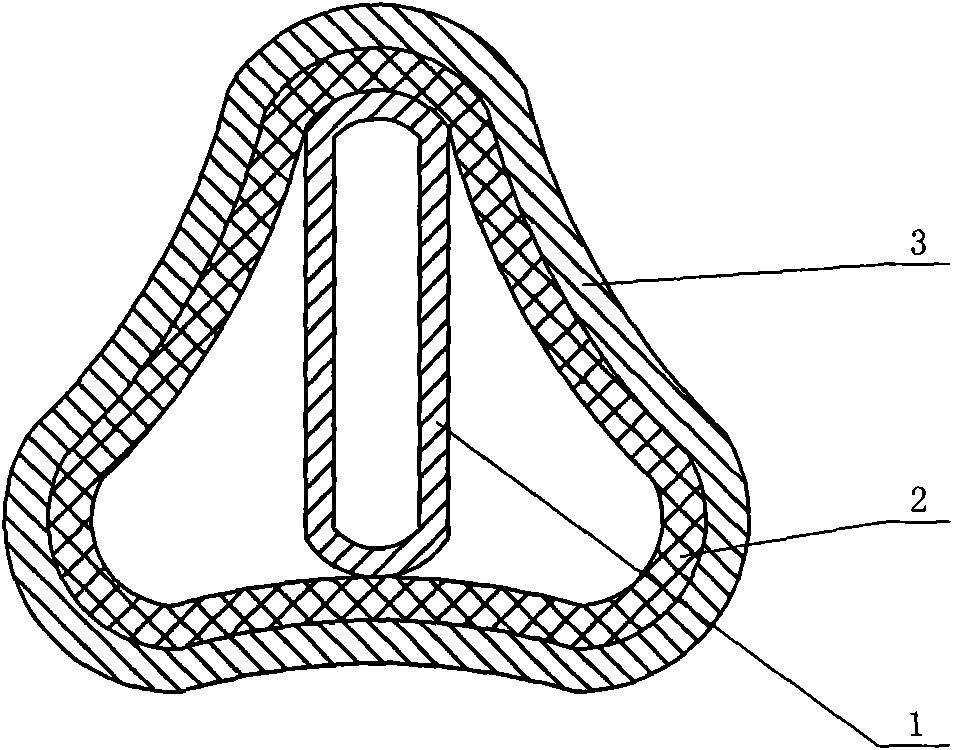

[0013] Such as figure 1 combine figure 2 As shown, the multi-head anti-corrosion screw pump with equal wall thickness includes a stator housing 3 with a rubber layer 2 inside and a hollow rotor 1. There is a rubber layer 2 in the stator housing 3, and a hollow rotor 1 is built in the rubber layer 2. The hollow rotor 1 is helical. The number of heads is 1, and the inner hole of the hollow rotor 1 is processed into a shape corresponding to the shape by using a special CNC machine tool, so that the wall thickness of the hollow rotor 1 is equal; the number of spiral heads of the stator housing 3 that matches the hollow rotor 1 is 2, using a special numerical control machine tool, process the inner hole of the stator housing 3 into a shape corresponding to the shape, so that the wall thickness of the stator housing 3 is equal, and cast a rubber layer 2 of equal thickness along...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap