Copper film shielded transposition wire and production method

A technology of transposition wires and shielding wires, which is applied in the field of transformers, can solve problems such as the reduction of shielding effects, and achieve the effects of improved winding manufacturability, high efficiency, and improved winding manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

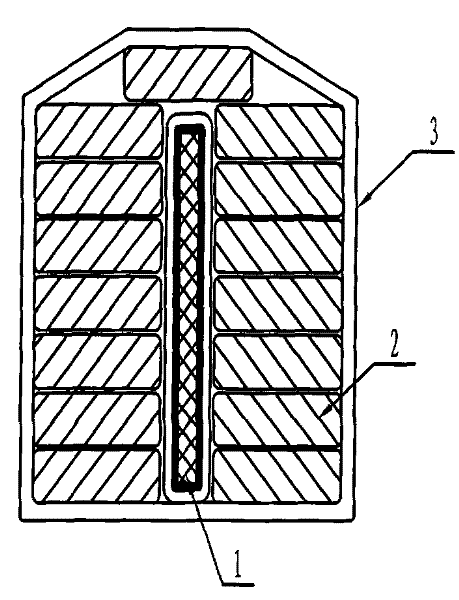

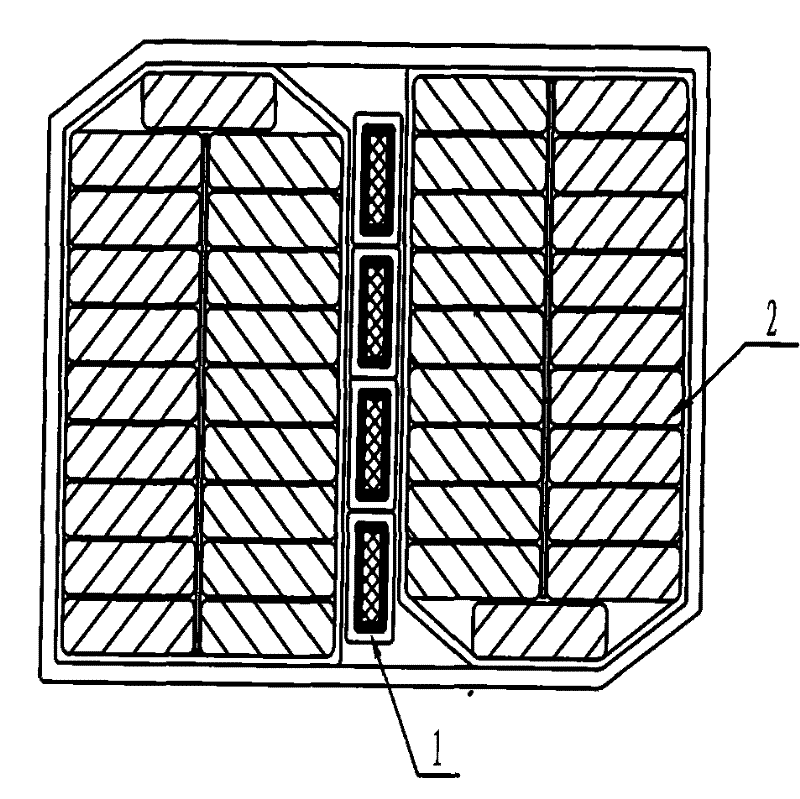

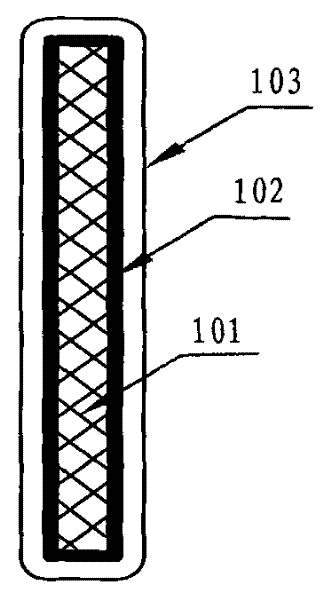

[0029] 1. See Figure 1 to Figure 6 , the copper film shielding transposition wire, the structure includes, inside a single transposition wire ( figure 1 ) or combined two conductors ( figure 2 ) is sandwiched between a shielded wire layer 1, and the single transposed wire is composed of two rows of multiple single flat wires 2 (thereby insulated with resin paint film or insulating backing paper, the structure can be the same as the prior art), the described The shielded wire layer 1 is copper film shielded wire layer, and there is one copper film shielded wire layer ( figure 1 ), or by 2 or more ( figure 2 ) The copper film shielding wire sheets are arranged in the direction of the sheet direction. The structure of the copper film shielding wire is: a copper film 102 is provided on the outside of the insulating plate skeleton 101, and an insulating material layer 103 is provided on the outside of the copper film 102. There is an inner insulating layer between the shielde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com