Array package substrate

An array packaging and substrate technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as solder balls falling off easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

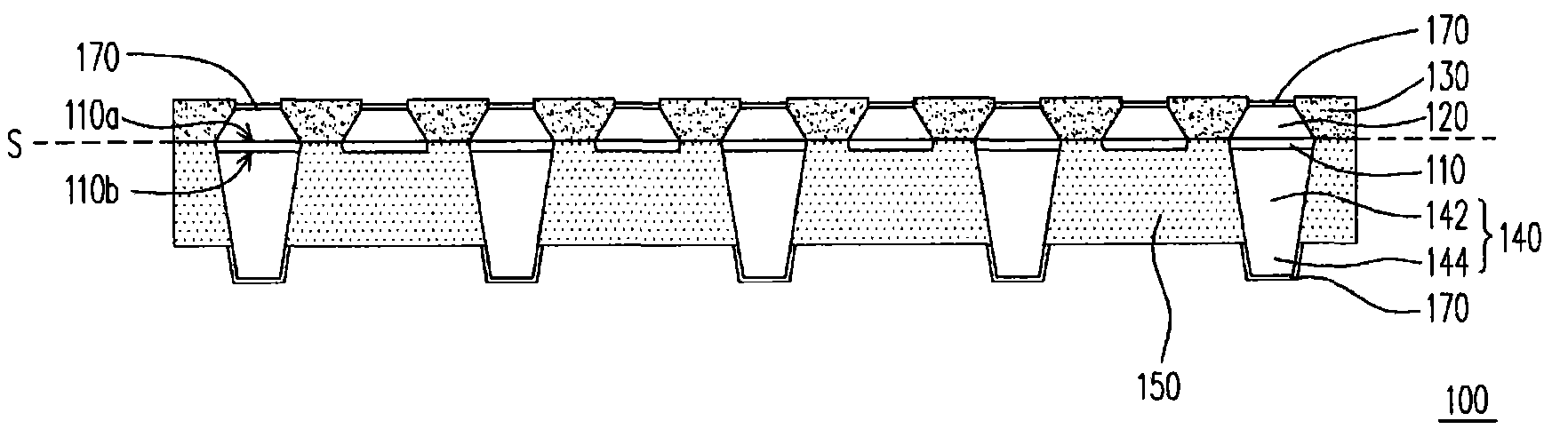

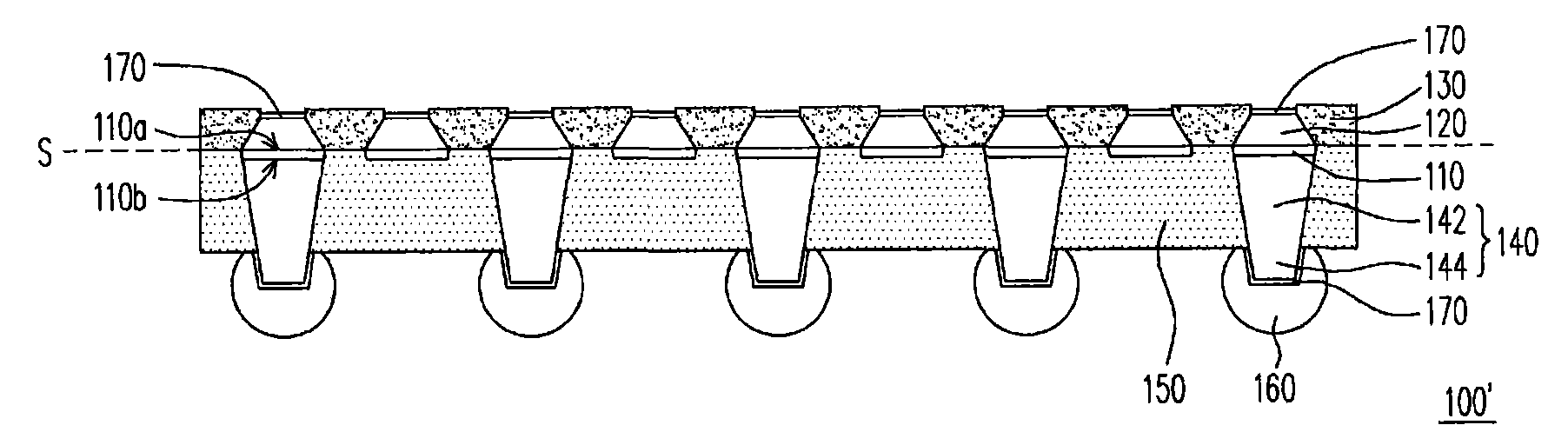

[0026] figure 1 A schematic diagram of an array packaging substrate according to an embodiment of the present invention is shown. Please refer to figure 1 , the array package substrate 100 of this embodiment is used to carry a semiconductor element such as a chip. The array package substrate 100 mainly includes a patterned metal connection layer 110 (patterned metal connection layer 110 is an etch barrier layer) made of nickel or nickel chrome, a plurality of pads 120 made of copper, a first The insulating layer 130 , a plurality of conductive studs 140 made of copper, for example, and the second insulating layer 150 . In this embodiment, the patterned metal connection layer 110 has a first surface 110a and a second surface 110b corresponding to the first surface 110a, the pads 120 are disposed on the first surface 110a, and the conductive bumps The post 140 is disposed on the second surface 110b. In this way, the conductive bumps 140 can be electrically connected to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com