Antistatic styrenic polymer compositions and articles therefrom

A technology of styrene polymers and compositions, which can be used in transportation, packaging, thin material handling, etc., and can solve the problems of reduced mechanical properties, fragility, and low impact strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

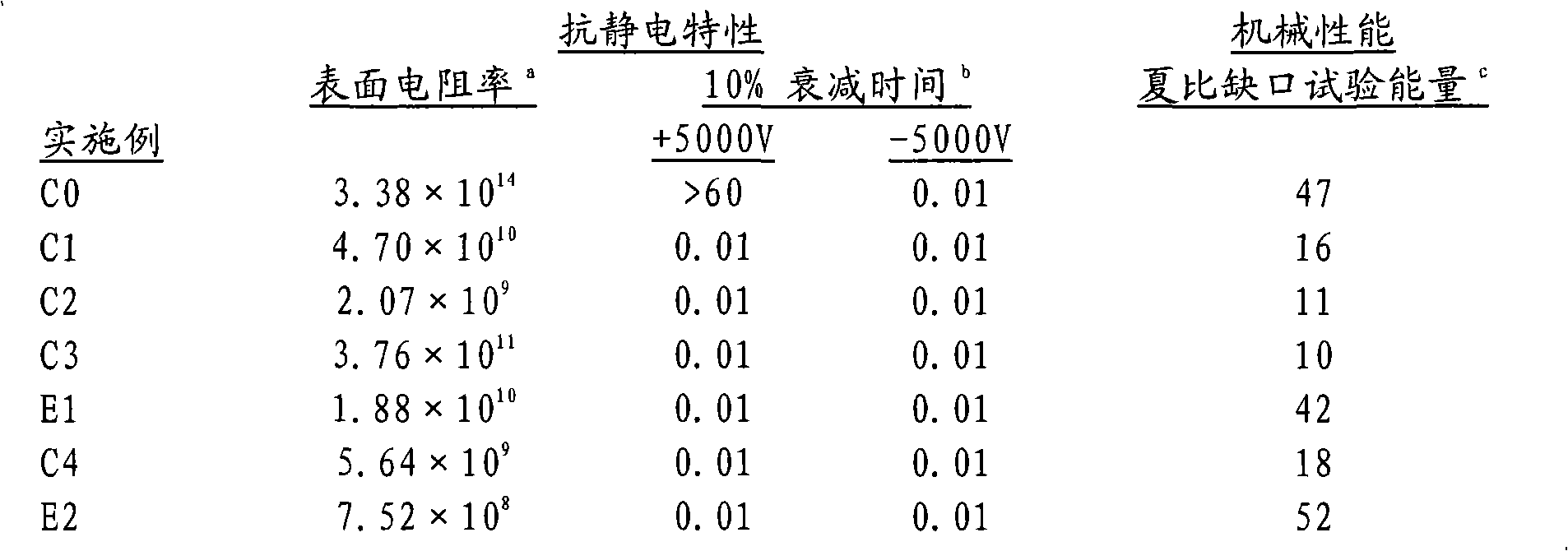

Examples

Embodiment

[0028] According to the invention, the polymer composition is prepared using:

[0029] Acrylonitrile Butadiene Styrene (ABS) : P2H-AT 792 from LANXESSAG.

[0030] KI (potassium ionomer) : Entira TM AS, available from DuPont, is an E / X / Y potassium ionomer, where E is ethylene, X is methacrylic acid (14.9% by weight), and Y is methyl acrylate (0.9% by weight); using K ions partially neutralized the mixed acid to 84.8%. MFI (melt flow index, measured at 190° C. and 2.16 kg) was 1.

[0031] KI-G : Available from Mitsui DuPont Poly Chemical Co., Ltd. It is a premix of glycerol and potassium ionomer consisting of (a) potassium ionomer consisting of E / X potassium ionomer, where E is ethylene and X is methacrylic acid (12.5% by weight ), the acid moiety is neutralized to 82% with potassium ions; and (b) a glycerol composition of 5% by weight. The MFI is 1.

[0032] KI-DG : a premix of diglycerol and potassium ionomer, prepared from (a) with the above-mentioned Entira...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com