Knitting method of tubular fabric and weft knitting machine

A technology of tubular knitting and flat knitting machines, applied to flat knitting machines with individual moving needles, weft knitting, knitting, etc., to achieve the effect of improving weaving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

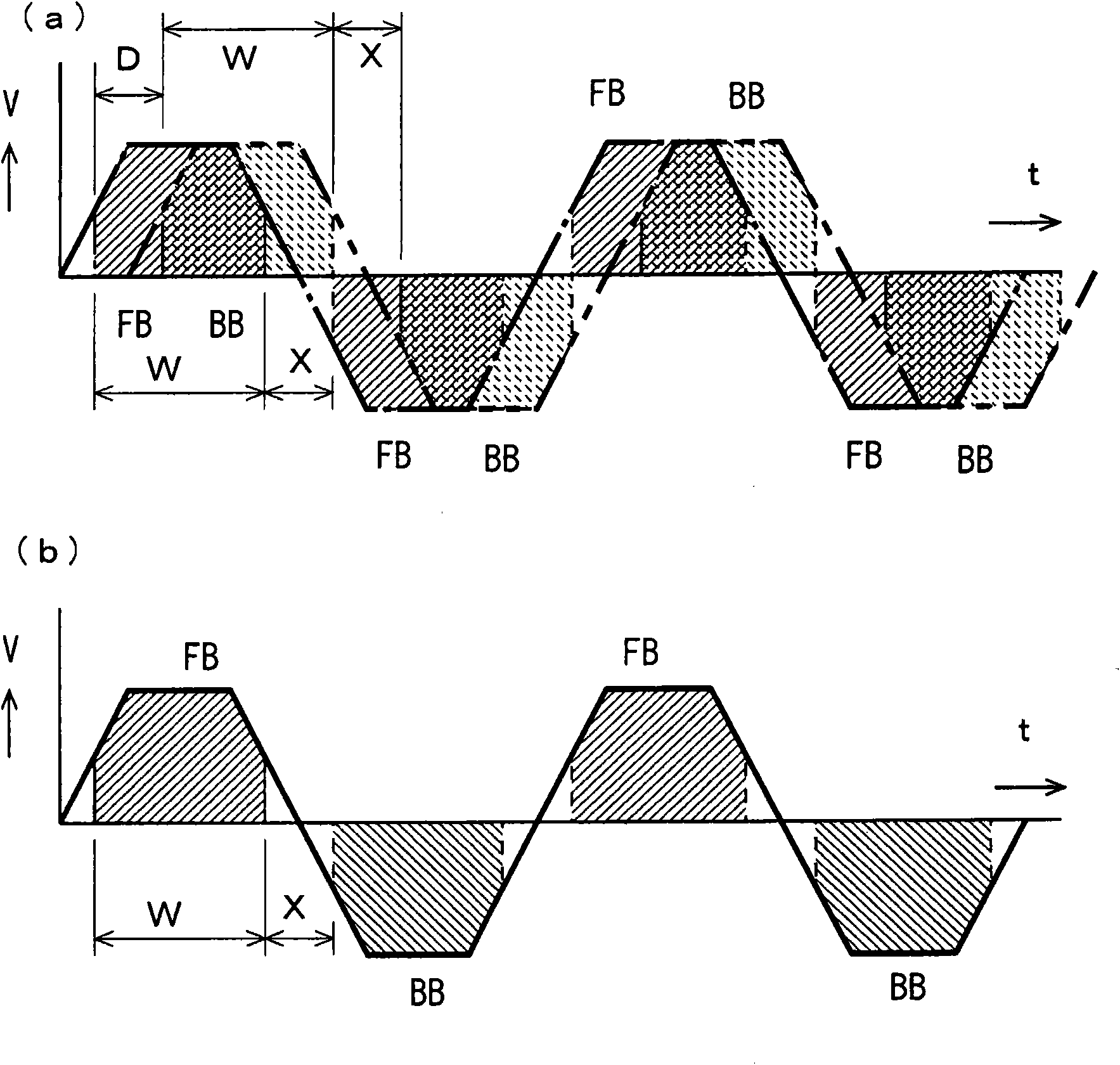

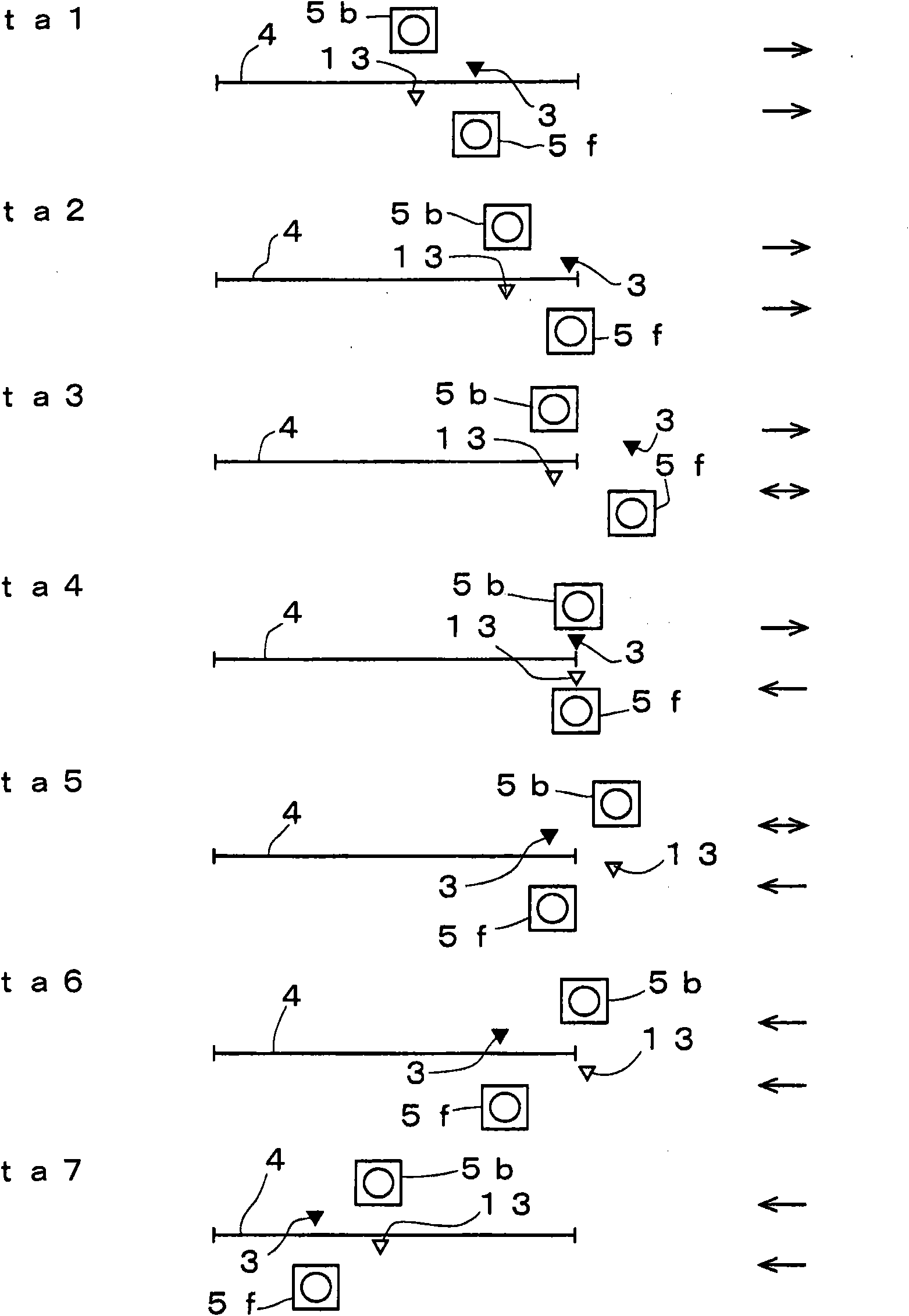

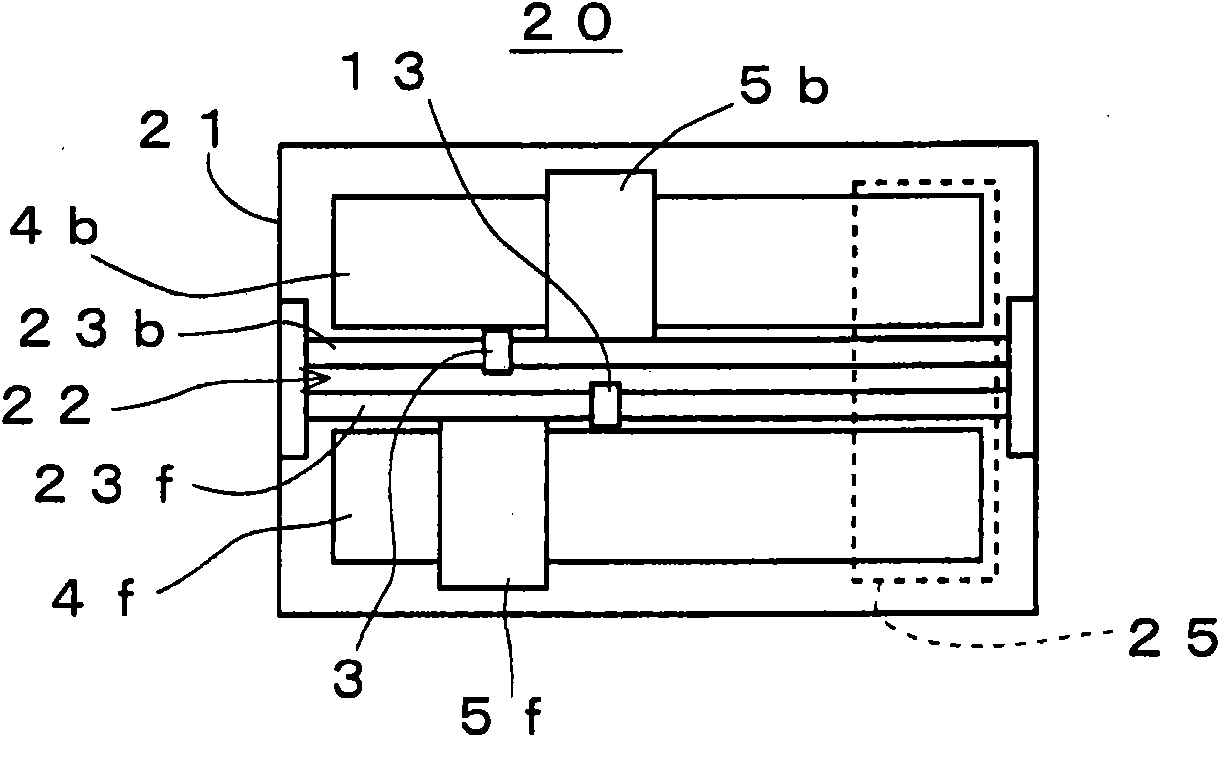

[0031] figure 1 The basic idea of the knitting method of the tubular knitted fabric as an embodiment of the present invention is shown in comparison with the knitting method of the tubular knitted fabric woven by the conventional endless knitting. That is, in the present invention, as in figure 1 As shown in (a) as the change of the moving speed V with time t, in a flatbed knitting machine having a pair of needle beds such as the front needle bed FB and the rear needle bed BB, as indicated by the one-dot chain line and the two-dot chain line shows, weaving with a phase difference corresponding to the time difference D of weaving start Figure 9 (a) The tubular knitted fabric 11 as shown. The phase difference is provided so that the knitting needles performing the knitting operation moving in and out of the needle bed from the front and rear needle beds are spaced so that they do not interfere with each other. The position where the knitting needles are driven to carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com