Tool holder equipped with a damping means

A shock absorber, tool holder technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

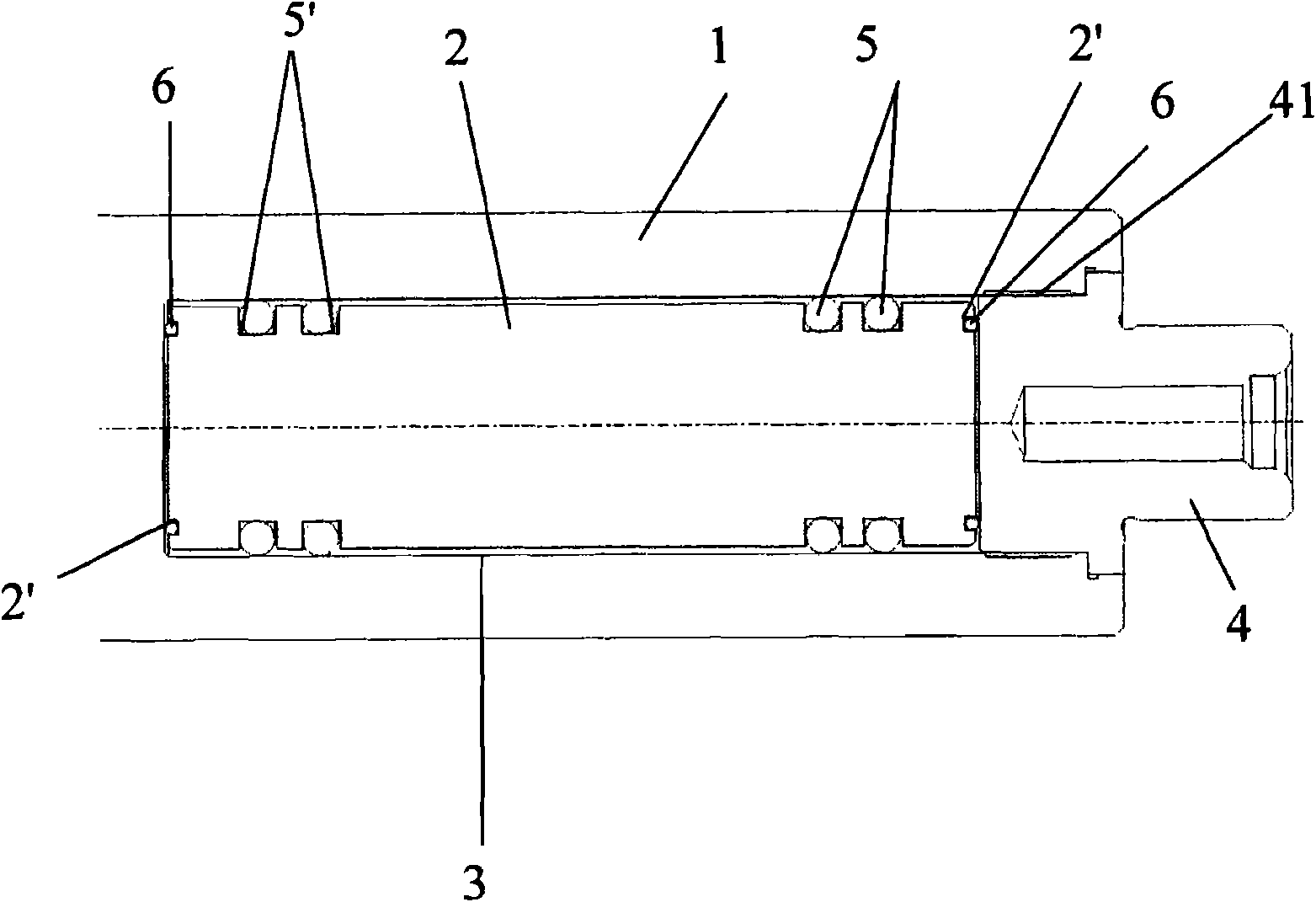

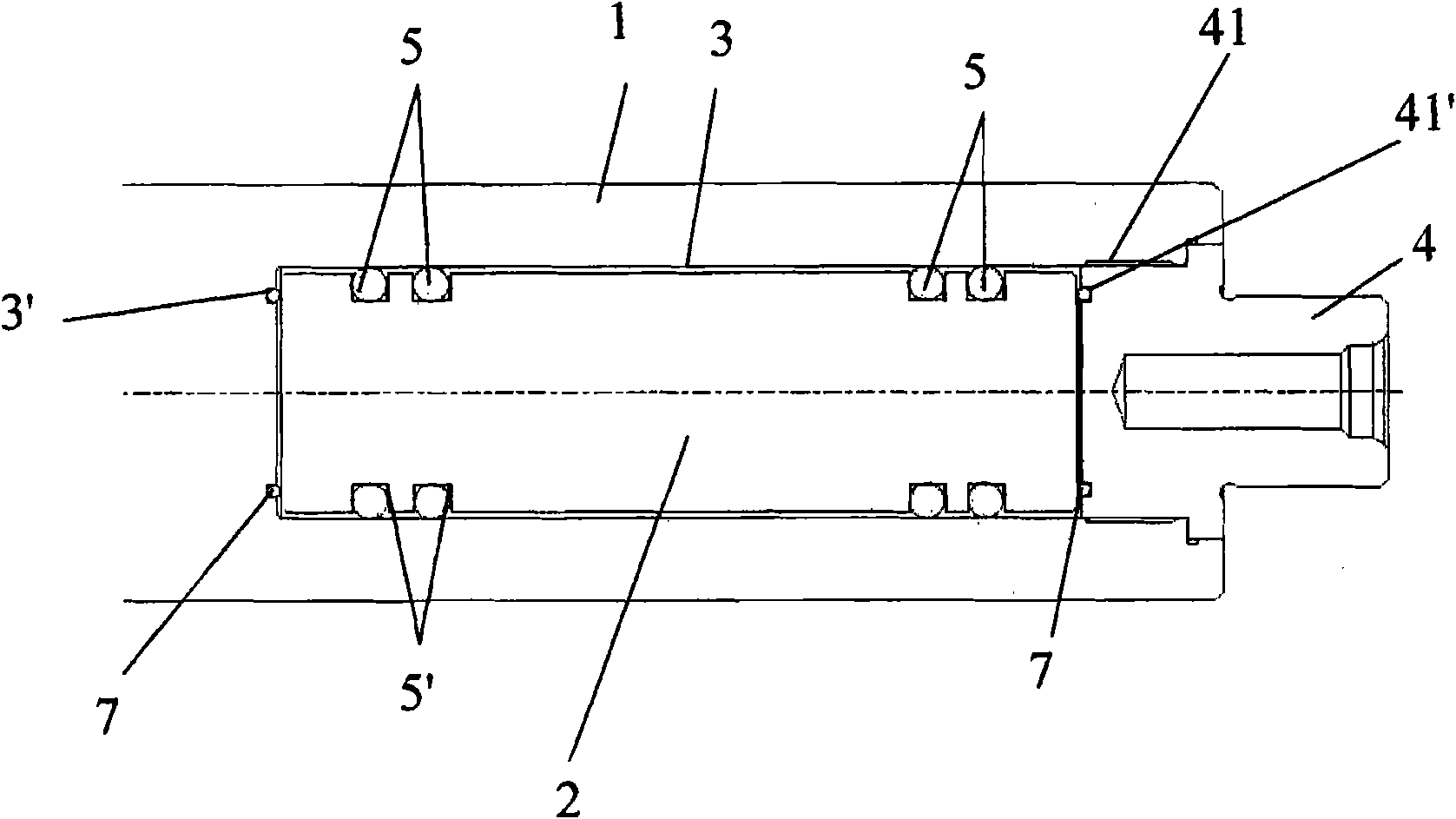

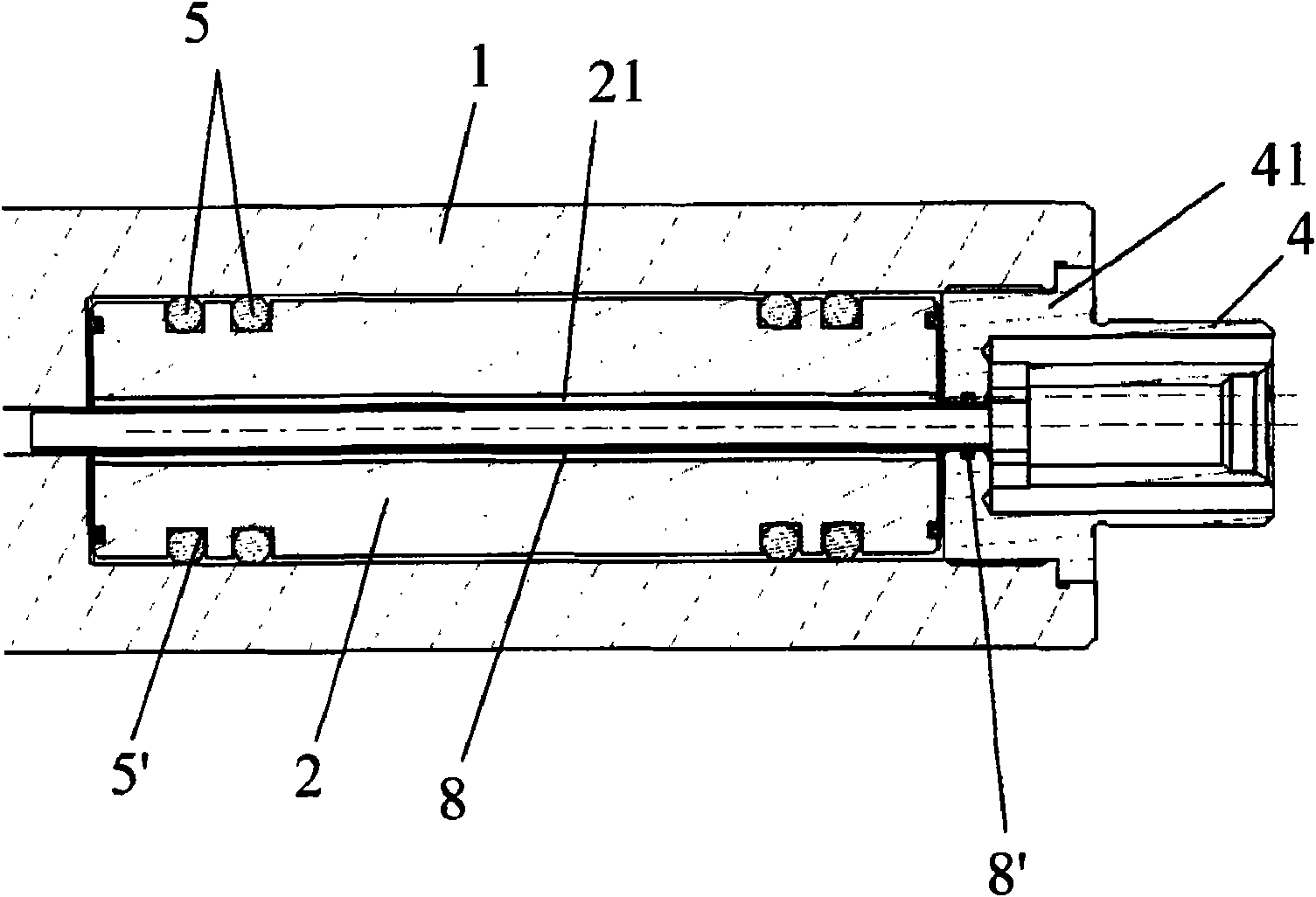

[0015] Figures 1 to 3 Shown as an example is a tool holder 1 in the form of a reaming head, which is provided with an elongated shock absorber 2 arranged in a housing 3 at the end of the tool holder 1, which has a corresponding shape and size and It is closed at its ends by a body 4 for receiving a reaming head. It is known that the end of the chamber 3 of the tool holder 1 is closed by directly screwing the body 4 for receiving the reaming head with the centering device 41, or by fitting the body 4 in the end of the chamber with screws to achieve. Figures 1 to 3 An example of an embodiment of the invention is shown, but it is obvious that the invention can also be applied, for example, in milling cutter holders.

[0016] It is known that the housing 3 of the tool holder 1 is made in such a way that, relative to a solid cylinder, at most only a 5% loss of static stiffness occurs and the depth of the housing is equal to twice the diameter of the tool holder 1. times. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com