Glass fiber reinforced plastic plate structure and method for preparing glass fiber reinforced plastic plate with same

A technology of glass fiber reinforced plastics and plates, applied in chemical instruments and methods, glass/slag layered products, lamination devices, etc., can solve the problems of heavy weight, high plate density, poor heat dissipation, etc., reduce material costs, and simple preparation method , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

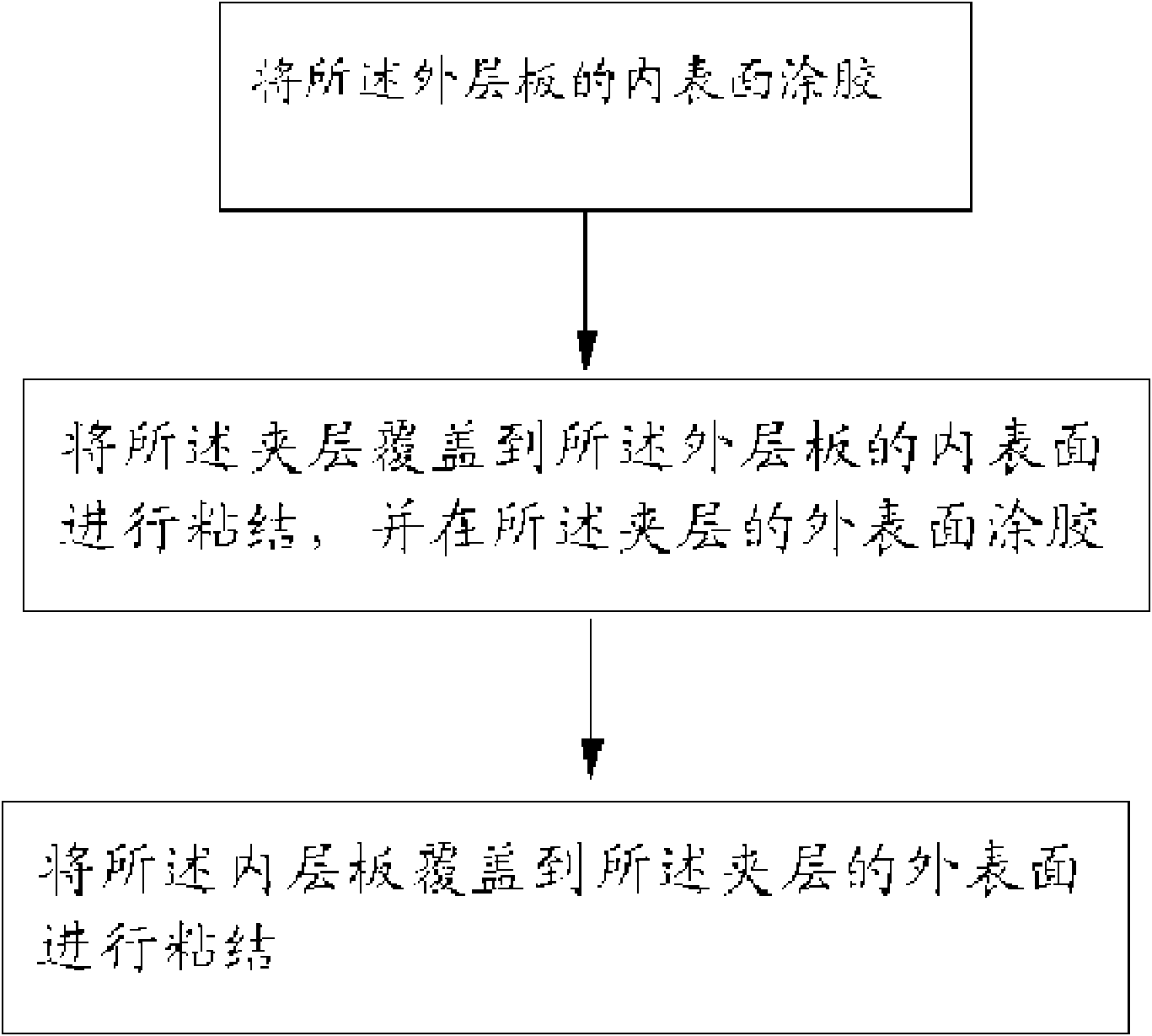

[0020] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

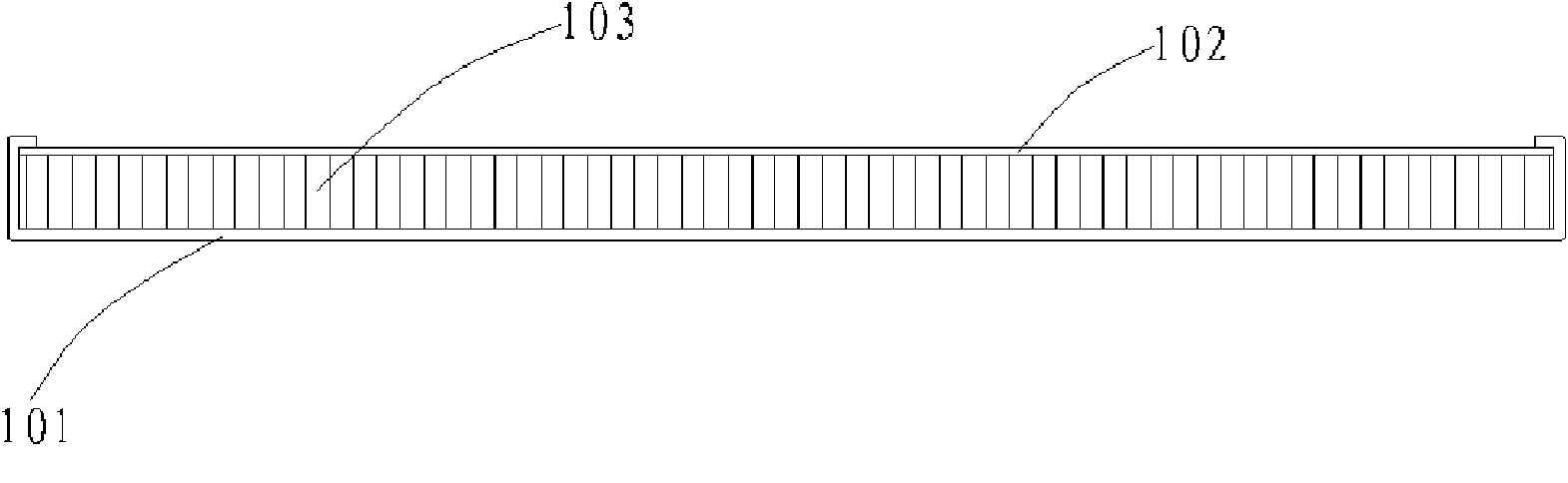

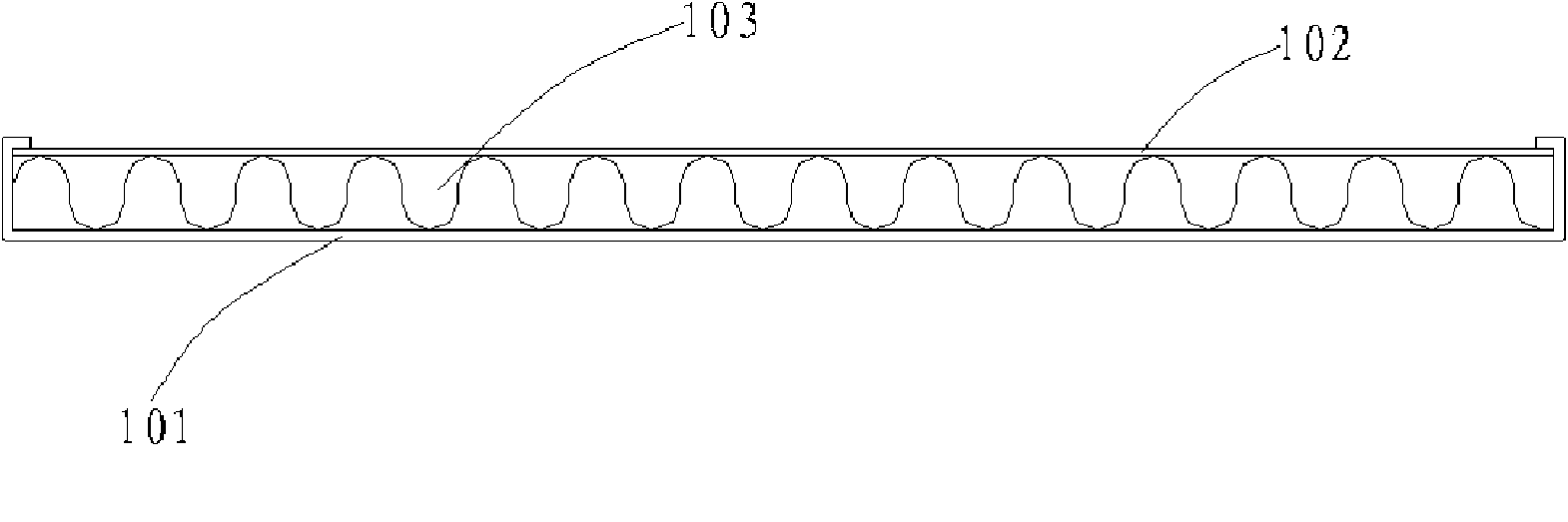

[0021] see figure 1 A glass steel plate structure of the present invention and the first structure schematic diagram of the glass steel plate in the glass steel plate preparation method of the structure and figure 2 A schematic diagram of a second structure of a glass steel plate in a glass steel plate structure of the present invention and a method for preparing the glass steel plate of the structure. As shown in the figure, the FRP plate structure includes at least three layers, which are an outer layer plate 101, an inner layer plate 102 and an interlayer 103, and the interlayer 103 is arranged on the outer layer plate 101 and the inner layer plate 102. In the middle, wherein, the interlayer 103 is one or more layers.

[0022] In the preferred technical solution of the present invention, the glass steel plate is a three-layer structure, including ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com