Electroforming metal film mesh plate for printing touch mesh spacing contacts

A metal film and touch screen technology, used in printing, printing presses, rotary printing presses, etc., can solve the problems of difficulty in controlling the size of screen spacing points, affecting the precision of graphic precision printing, and inability to achieve thin film printing, etc. Excellent solvent resistance and high printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

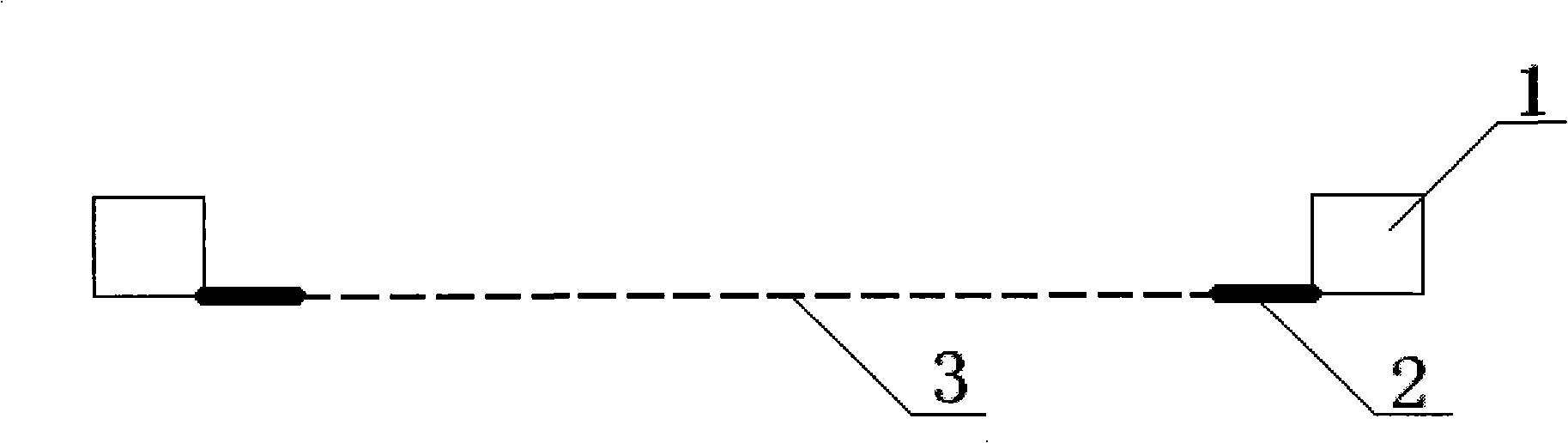

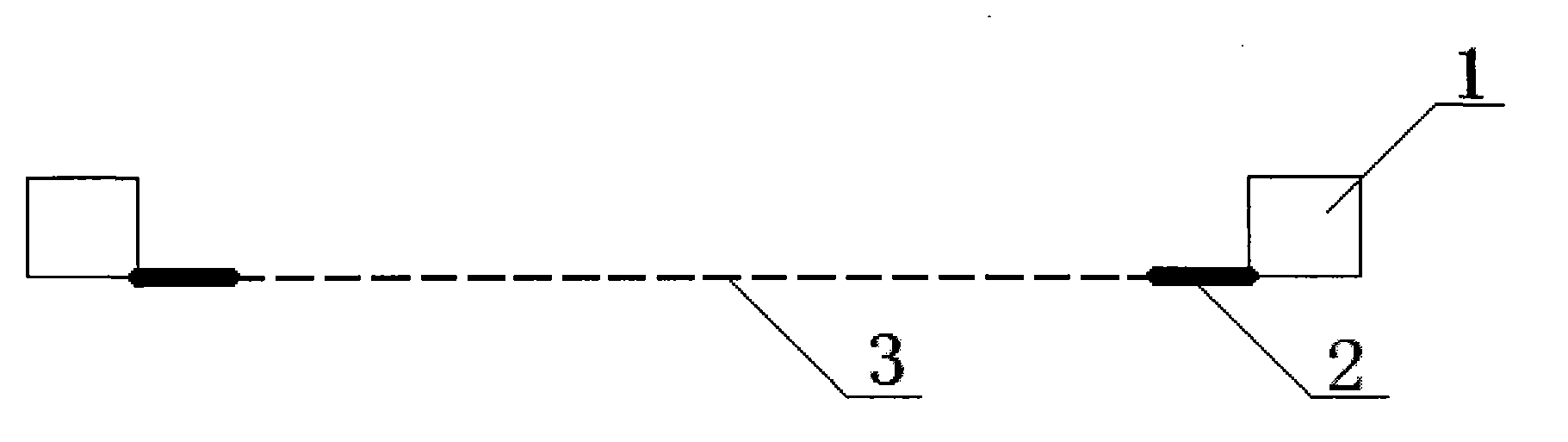

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The electroformed metal film screen plate for printed touch screen interval points of the present invention is structurally divided into three parts: an aluminum alloy profile screen frame 1, a nylon screen 2, and a metal film 3. The aluminum alloy profile screen frame 1 can be hollow, cross-reinforced or solid cast aluminum according to customer requirements, and the size and specifications can be set according to customer requirements. Nylon wire mesh 2 is used to connect aluminum alloy profile frame 1 and metal film 3 to maintain tension. The specifications range from 60 to 200 mesh. The junction of the metal film 3 is bonded with cured glue, so that the metal film 3 is flat and has a certain tension. The tension is 15-30N, which meets the needs of precision printing. The metal film 3 is formed by electroforming, with a hardness of 450-500 Hv and a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com