Window body component of composite heat insulating wall body and construction method thereof

A composite thermal insulation and wall technology, applied in the direction of walls, windows/doors, building components, etc., can solve the problems of difficult overall building thermal insulation, backward installation methods, poor thermal insulation performance, etc., to ensure project quality, simple process, and easy installation fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

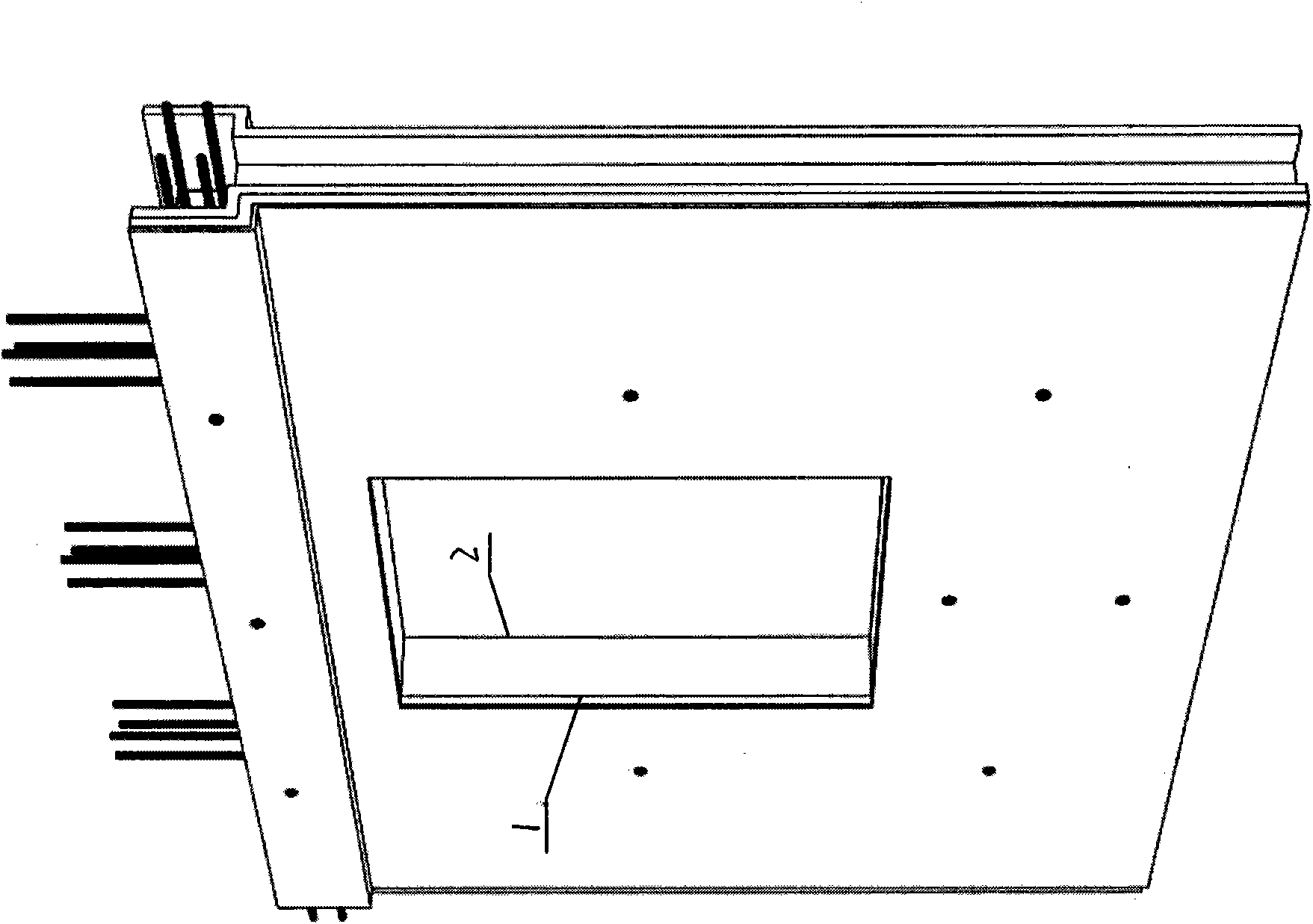

[0032] The present invention can be applied to the composite thermal insulation wall composed of the window that the applicant applied for before, the application number is 200810010118.7, and the title of the invention is "a composite thermal insulation wall composed of a window and its installation method";

[0033] The present invention is also applicable to common composite thermal insulation walls forming windows.

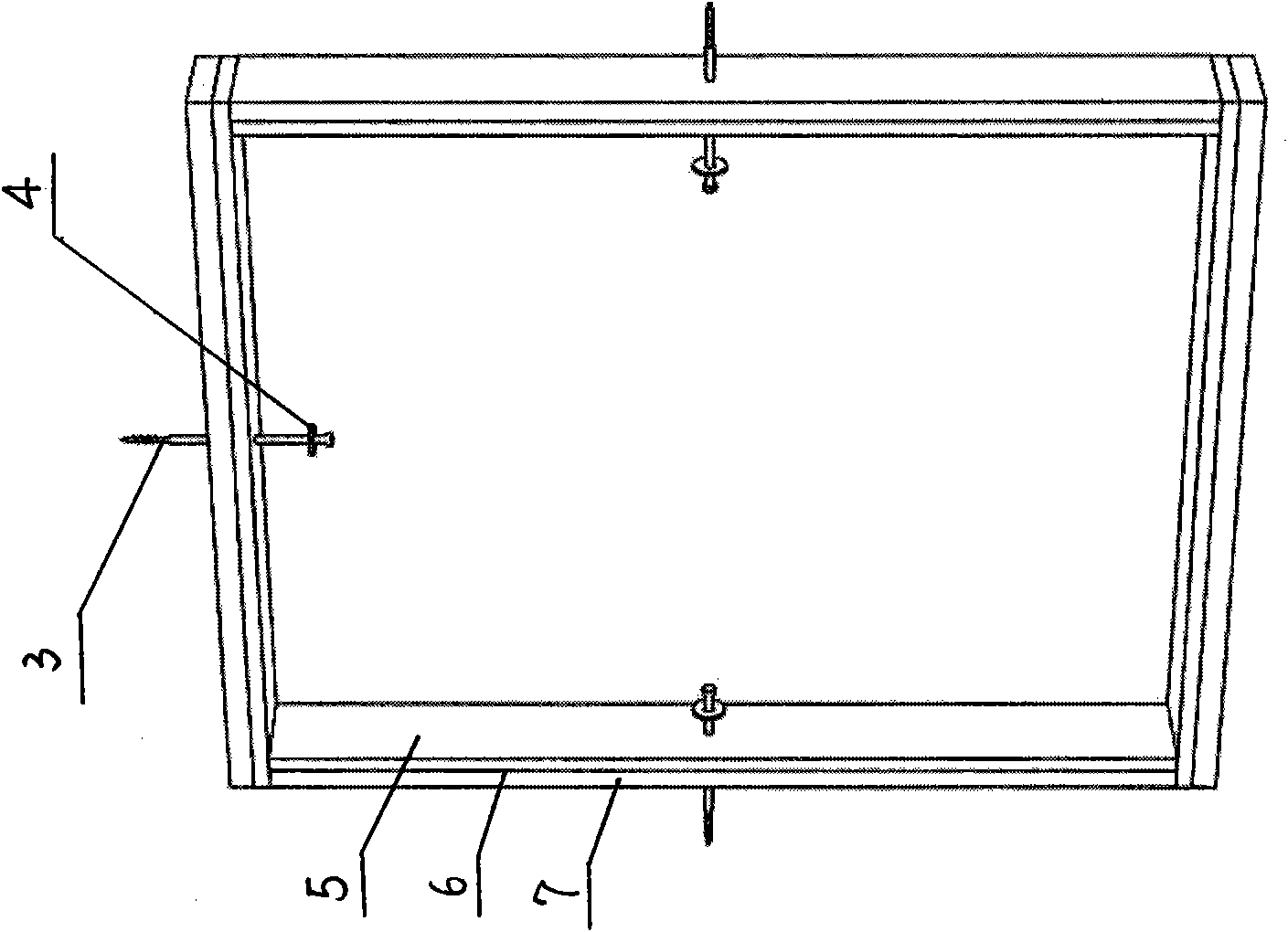

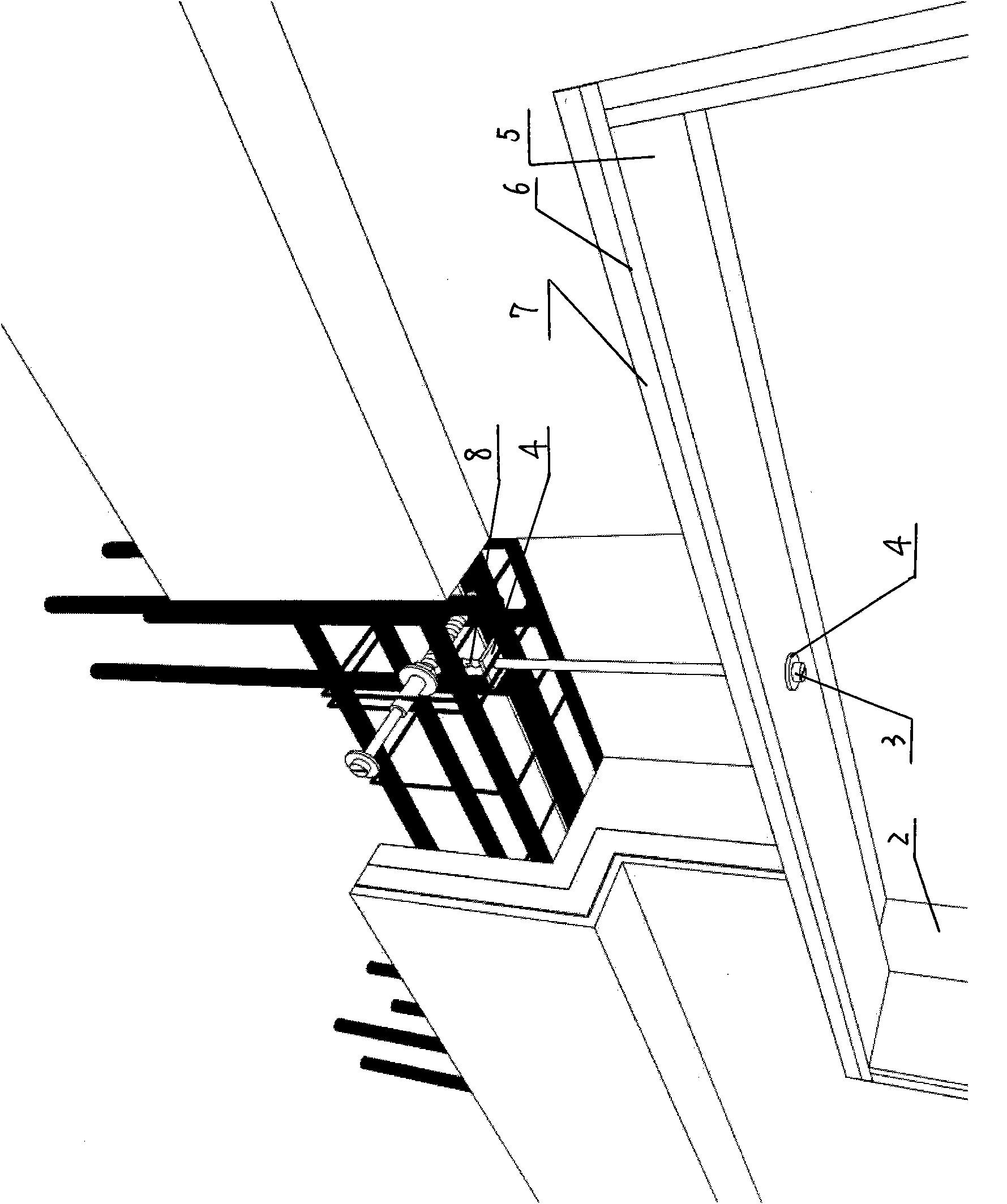

[0034] like Figure 1-16 As shown, the window assembly of the present invention includes an inner EPS board 10 and an outer guard plate. The outer guard plate is installed on the outside of the window 1 and consists of four plates, upper, lower, left, and right, and each plate is sequentially arranged from the outside to the inside. It is composed of a fireproof heat insulation layer 7, a fireproof heat insulation mold 6 and an impact plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com