Double-insulated cable

A double-layer insulation, cable technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of high accident rate, short circuit, flame retardant performance, electrical performance and radiation resistance performance can not be satisfied at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

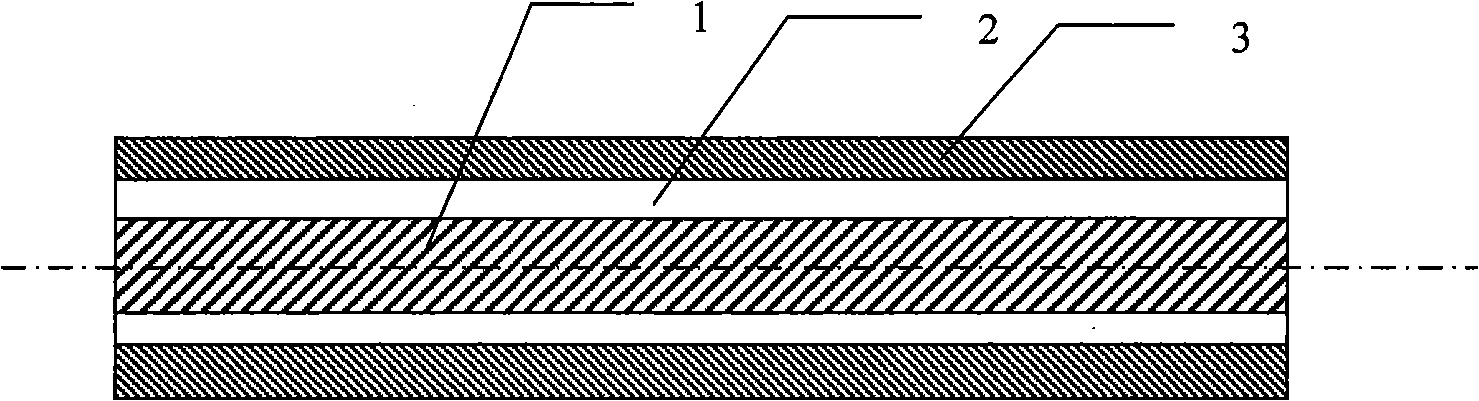

[0027] Double insulated cables, see figure 1 , there is an insulating layer inner layer 2 and an insulating layer outer layer 3 outside the conductive wire core 1. The inner and outer layers of the insulating layer are tightly bonded. The insulating inner layer 2 is made of low-smoke, halogen-free cross-linked polyethylene insulating material, and the insulating outer layer 3 is made of low-smoke, halogen-free, flame-retardant cross-linked polyolefin insulating material. The thickness of the inner layer 2 of the insulating layer is 0.15 mm, and the thickness of the outer layer 3 of the insulating layer is 0.45 mm.

[0028] The properties of inner and outer layer materials meet the following requirements:

[0029] Life expectancy ≥ 60 years;

[0030] Co with a dose of 25 Mrad 60 Radiation resistance;

[0031] Meet NES713 requirements, toxicity index ≤ 2.5;

[0032] Aging at 135±2℃ for 240 hours.

[0033] In addition, the insulation volume resistivity of the inner layer m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com