Frock clamp for turning flange spigot of complete machine motor

A technology of tooling fixtures and motors, which is applied in the field of tooling fixtures, can solve problems such as low machining accuracy, and achieve the effects of high production efficiency, high workpiece machining accuracy, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

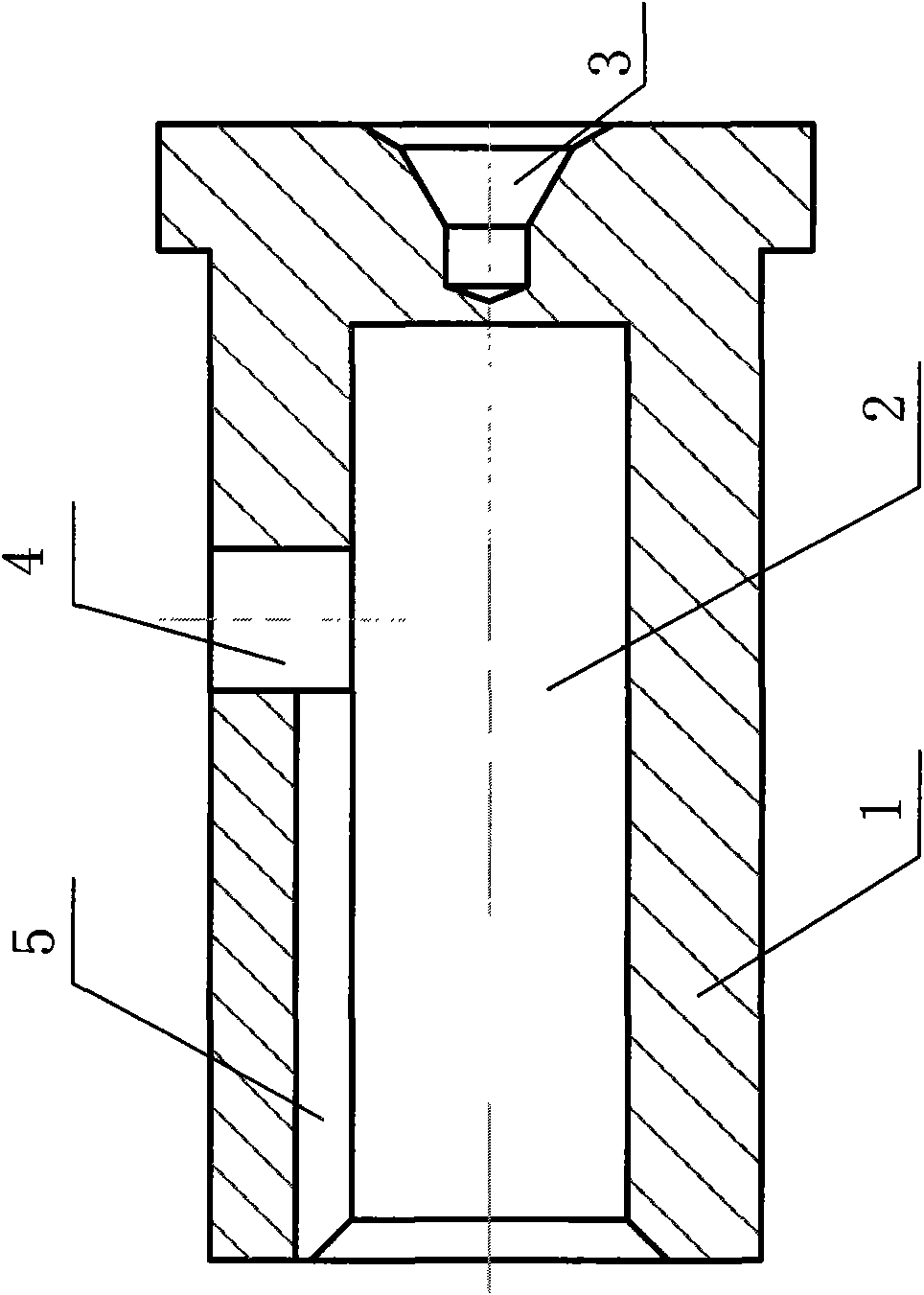

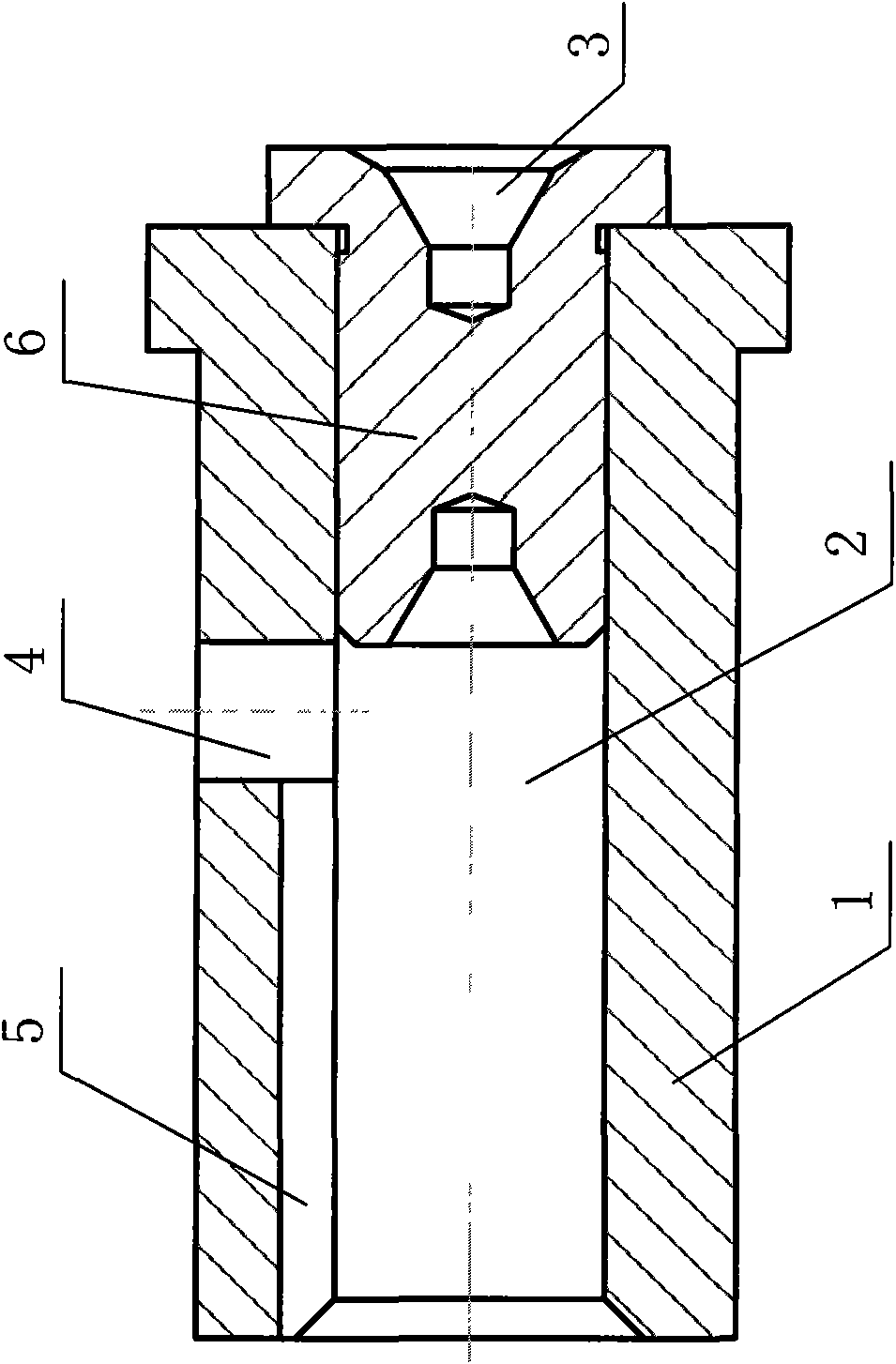

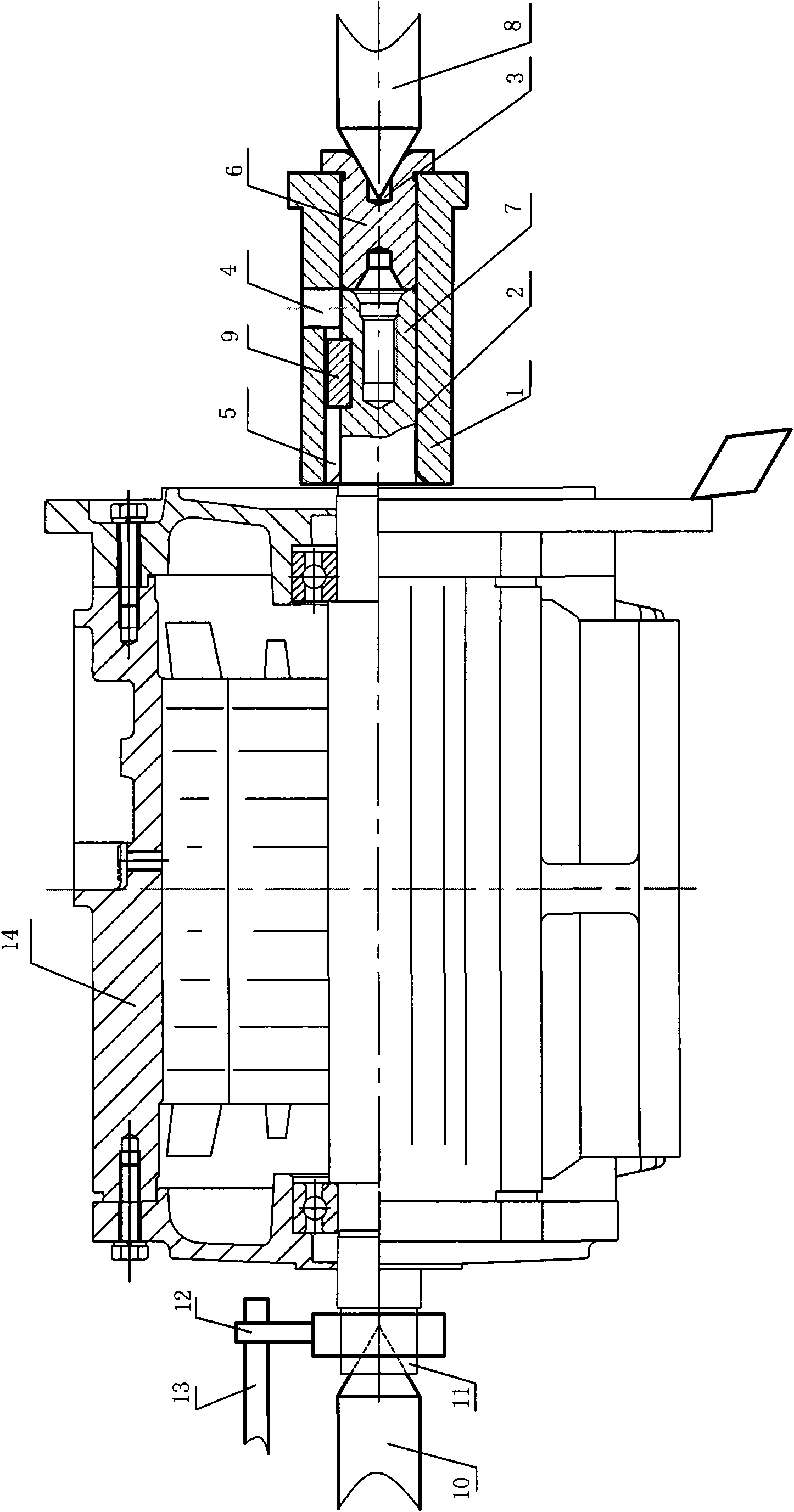

[0018] exist figure 1 Among them, a tooling fixture for turning the flange seam of a complete machine, including a positioning bushing 1 with an inner hole 1, the positioning bushing 1 is quenched and tempered by ordinary No. 45 steel.

[0019] Such as figure 1 As shown, a keyway 5 is opened on the hole wall of the inner hole 2 of the sleeve end of the positioning sleeve 1 .

[0020] The inner hole 2 of the sleeve end of the positioning sleeve 1 is matched with the shaft extension of the motor to be turned. The cooperation between the two adopts a small clearance fit with high precision. The matching clearance should ensure that the inner hole and the shaft extension of the motor are coated. After applying lubricating oil, screw the motor shaft into the inner hole by hand. If the gap is too small, it will be difficult to install; if the gap is too large, the machining accuracy of the flange seam cannot be guaranteed.

[0021] The purpose of opening the keyway 5 is to instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com