Cast-in-place light solid composite wall body of light steel truss structure and construction method thereof

A composite wall and construction method technology, applied in the direction of walls, building components, buildings, etc., can solve problems such as unacceptable, heat preservation, anti-corrosion, fire prevention, and poor sound insulation effects, so as to overcome poor heat preservation and fire resistance, and high construction efficiency , the effect of short working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

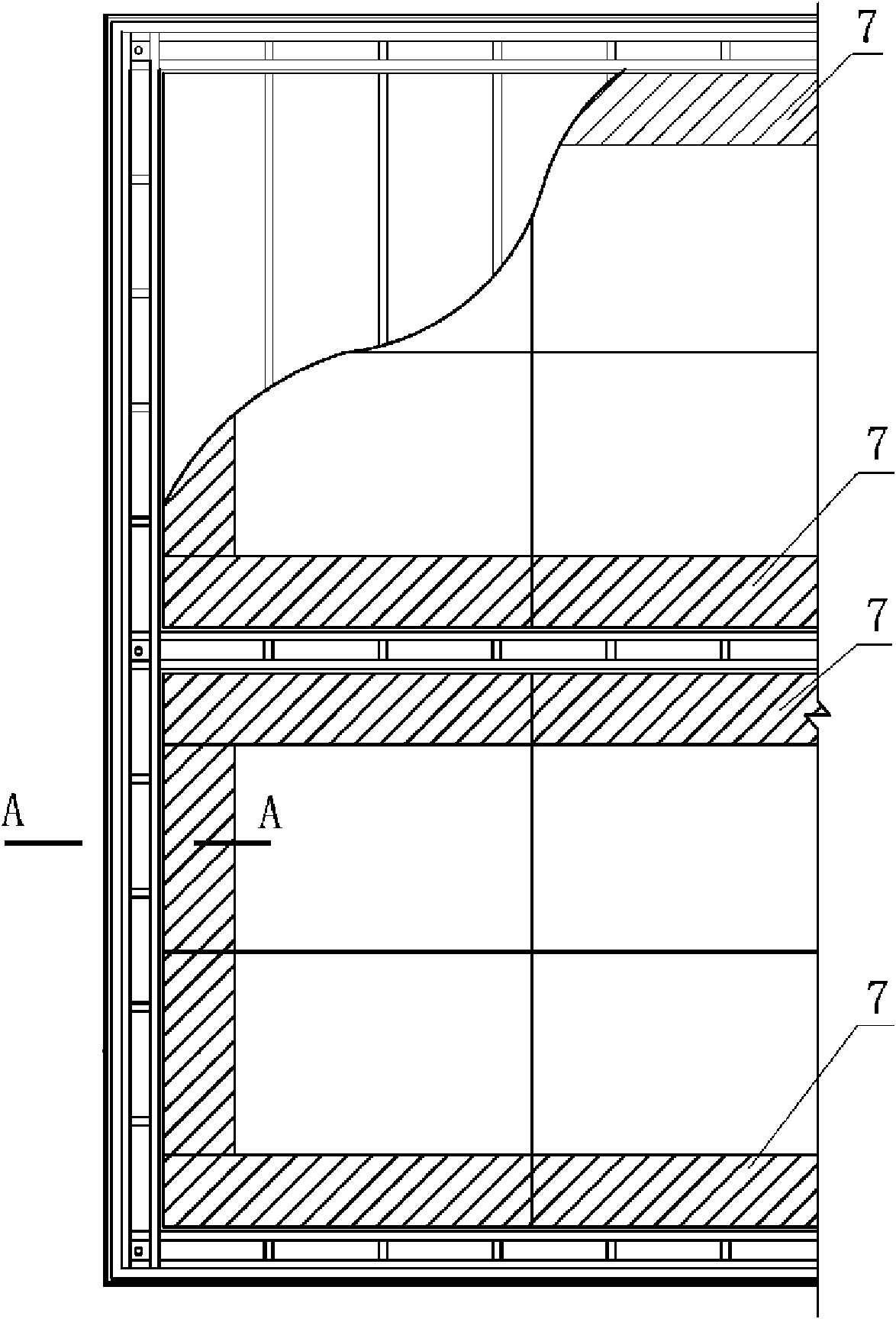

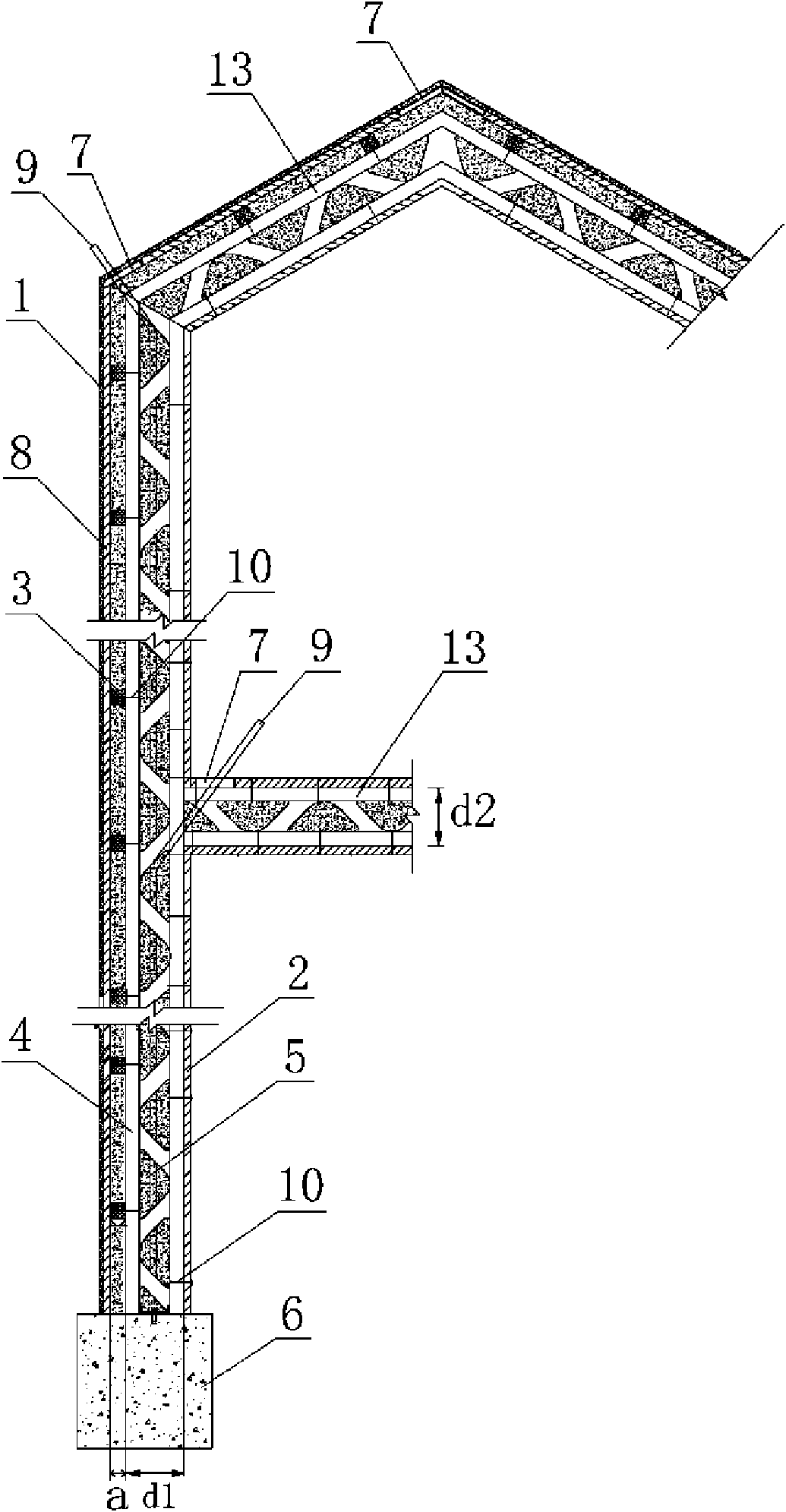

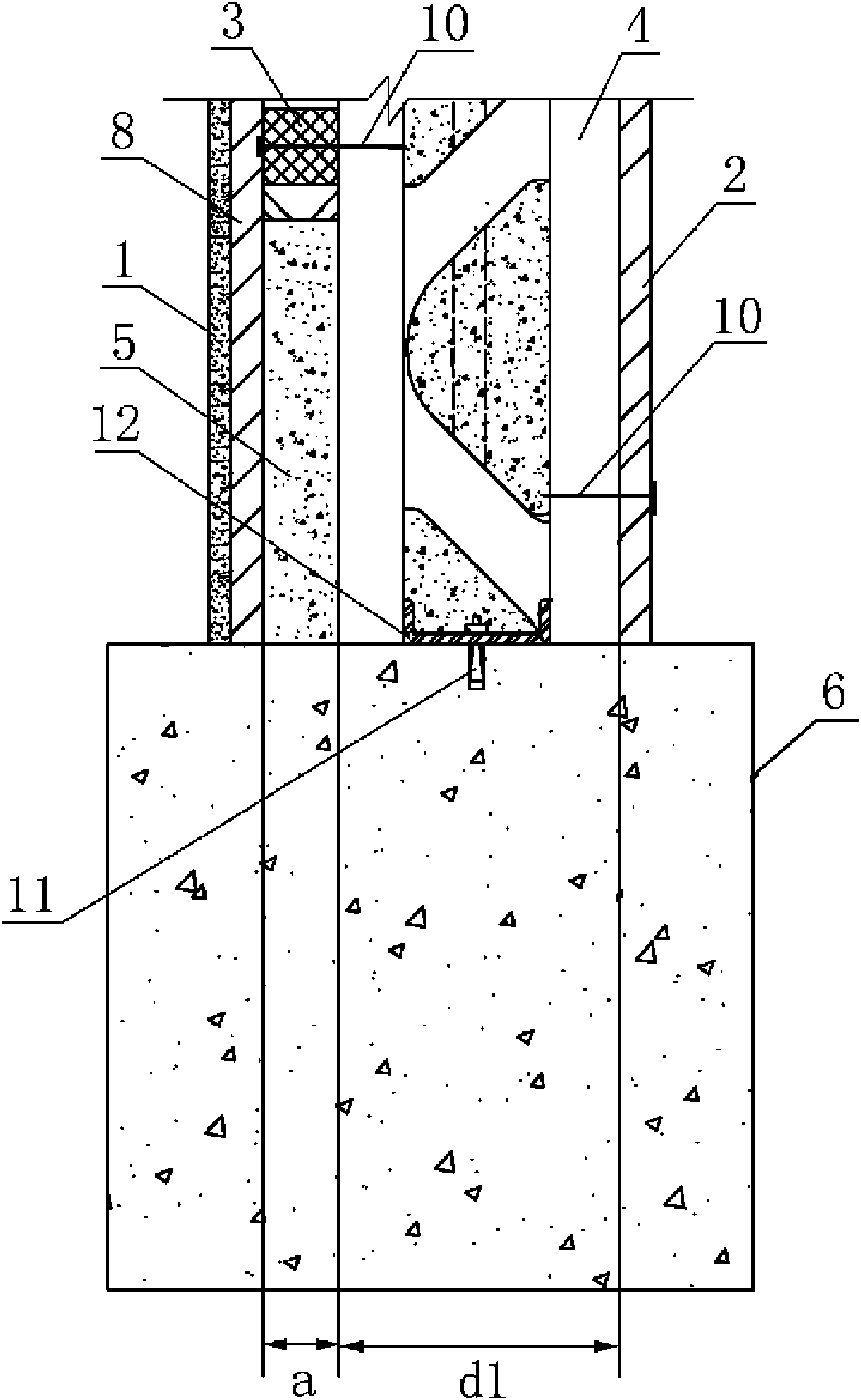

[0027] Examples see figure 1 , figure 2 As shown, the light steel truss cast-in-place lightweight solid composite wall has a skeleton of the wall light steel truss 4, and the wall light steel truss has two parallel chords and webs arranged in a continuous V shape between them. It is characterized in that: the wall light steel trusses 4 are vertically spaced in the composite wall, and the two chords are respectively located on the inner and outer sides of the wall. The outer side of the truss 4 is fixedly connected with pads 3 distributed in dots, the outer side of the pad 3 is covered with an outer prefabricated plate 8, and the gap between the inner prefabricated plate 2 and the outer prefabricated plate 8 and the light steel truss 4 is filled with thermal insulation filler material 5 The thermal insulation filling material 5 is foamed cement, perlite mortar, and ceramsite concrete; the bottom of the light steel truss 4 is fixedly connected to the concrete foundation 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com